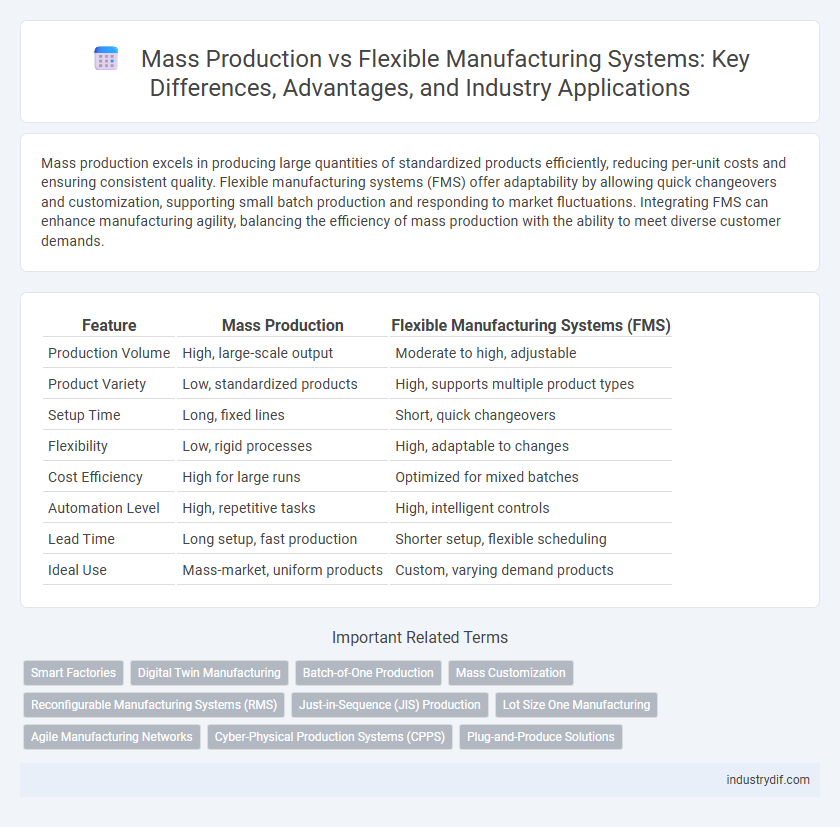

Mass production excels in producing large quantities of standardized products efficiently, reducing per-unit costs and ensuring consistent quality. Flexible manufacturing systems (FMS) offer adaptability by allowing quick changeovers and customization, supporting small batch production and responding to market fluctuations. Integrating FMS can enhance manufacturing agility, balancing the efficiency of mass production with the ability to meet diverse customer demands.

Table of Comparison

| Feature | Mass Production | Flexible Manufacturing Systems (FMS) |

|---|---|---|

| Production Volume | High, large-scale output | Moderate to high, adjustable |

| Product Variety | Low, standardized products | High, supports multiple product types |

| Setup Time | Long, fixed lines | Short, quick changeovers |

| Flexibility | Low, rigid processes | High, adaptable to changes |

| Cost Efficiency | High for large runs | Optimized for mixed batches |

| Automation Level | High, repetitive tasks | High, intelligent controls |

| Lead Time | Long setup, fast production | Shorter setup, flexible scheduling |

| Ideal Use | Mass-market, uniform products | Custom, varying demand products |

Introduction to Mass Production and Flexible Manufacturing Systems

Mass production involves the large-scale manufacturing of standardized products using assembly lines and specialized machinery to maximize efficiency and reduce costs. Flexible Manufacturing Systems (FMS) utilize computer-controlled machines and automated material handling to allow quick adjustments for producing a variety of products with minimal downtime. Both systems optimize production, but mass production emphasizes volume and consistency, while FMS prioritizes adaptability and customization.

Core Principles of Mass Production

Mass production relies on standardized processes, repetitive tasks, and high-volume output to achieve economy of scale and minimize per-unit cost. Core principles include assembly line operations, specialization of labor, and continuous flow production, which together optimize efficiency and consistency. This approach suits products with stable designs and predictable demand, enabling rapid manufacturing with minimal variation.

Key Features of Flexible Manufacturing Systems

Flexible Manufacturing Systems (FMS) integrate computer-controlled machines and automated material handling to enable rapid product changeovers and customization. Key features include high adaptability to varying product types, efficient resource utilization through real-time monitoring, and reduced downtime via automated scheduling and diagnostics. This technology supports small to medium batch sizes with agility, contrasting mass production's focus on high-volume, uniform output.

Historical Evolution of Manufacturing Approaches

Mass production, pioneered in the early 20th century with Henry Ford's assembly line, revolutionized manufacturing by enabling the large-scale production of standardized products with minimal costs. Flexible Manufacturing Systems (FMS), developed in the late 20th century, introduced automation and computer-controlled machinery to allow for adaptable production processes catering to customized outputs. The shift from rigid mass production to flexible systems reflects the industry's response to market demand for variety and rapid product changeovers.

Efficiency and Productivity Comparison

Mass production excels in efficiency through standardized processes and high-volume output, minimizing per-unit costs by leveraging assembly line automation. Flexible manufacturing systems (FMS) enhance productivity by rapidly adapting to product variations and reducing changeover times, enabling customized production without sacrificing speed. Comparing both, mass production achieves superior efficiency in uniform product runs, while FMS optimizes productivity in environments requiring diversity and quick responsiveness.

Customization Capabilities in Manufacturing

Flexible Manufacturing Systems (FMS) offer superior customization capabilities compared to Mass Production by enabling rapid changes in product design and batch sizes without significant downtime. FMS leverages automation and computerized controls to adapt quickly to customer-specific requirements, supporting a diverse product mix. This contrasts with traditional Mass Production, which prioritizes high-volume output but limits customization due to standardized processes and tooling.

Cost Implications and Scalability

Mass production offers lower unit costs due to economies of scale but requires higher initial capital investment and lacks flexibility for product variation. Flexible Manufacturing Systems (FMS) incur higher setup and technology costs but enable quick adaptation to market changes, reducing downtime and inventory expenses. Scalability in mass production is straightforward through volume increases, while FMS scales more efficiently by adjusting production types without significant additional costs.

Technology Integration in Modern Manufacturing

Mass production relies on standardized technology integration to achieve high output with minimal variation, emphasizing automation and assembly line processes. Flexible Manufacturing Systems (FMS) incorporate advanced robotics, computer-aided design (CAD), and real-time data analytics to enable rapid adaptation to product changes and customization. The integration of IoT sensors and AI-driven control systems in FMS enhances efficiency and responsiveness, bridging the gap between large-scale production and manufacturing versatility.

Quality Control and Consistency

Mass production ensures high quality control and consistency by utilizing standardized processes and automation to produce large volumes of identical products with minimal variation. Flexible manufacturing systems (FMS) enhance quality control by integrating advanced sensors and real-time monitoring, allowing swift adjustments to maintain product standards across diverse product types. Both systems employ rigorous inspection protocols, but mass production prioritizes uniformity while FMS emphasizes adaptability without compromising consistency.

Future Trends in Manufacturing Systems

Future trends in manufacturing systems emphasize increased adoption of flexible manufacturing systems (FMS) driven by advancements in automation, artificial intelligence, and IoT integration. Unlike traditional mass production, FMS offers scalable customization and rapid adaptation to market demands, reducing downtime and material waste. Enhanced data analytics and machine learning algorithms optimize production scheduling and quality control, propelling manufacturing toward smart, agile factories.

Related Important Terms

Smart Factories

Smart factories leverage flexible manufacturing systems (FMS) to optimize production agility, enabling rapid customization and real-time adjustments unlike traditional mass production that emphasizes high-volume, standardized output. Integration of IoT, AI, and robotics in FMS empowers smart factories to reduce downtime, enhance efficiency, and respond swiftly to market demand fluctuations.

Digital Twin Manufacturing

Digital Twin Manufacturing integrates virtual replicas of physical production systems, enabling real-time data analysis and simulation that enhance the adaptability of Flexible Manufacturing Systems (FMS) compared to traditional Mass Production methods. This digital framework improves operational efficiency, reduces downtime, and supports rapid customization by continuously monitoring and optimizing manufacturing processes.

Batch-of-One Production

Mass Production excels in high-volume, standardized output but lacks adaptability for Batch-of-One Production, which demands customized, low-volume manufacturing. Flexible Manufacturing Systems leverage automation and modular equipment to efficiently produce individualized products, reducing lead times and enhancing responsiveness to customer-specific requirements.

Mass Customization

Mass customization leverages flexible manufacturing systems to efficiently produce tailored products at near mass production speeds, combining product variety with high volume output. This approach enhances customer satisfaction by allowing personalized specifications without sacrificing cost-effectiveness or production efficiency.

Reconfigurable Manufacturing Systems (RMS)

Reconfigurable Manufacturing Systems (RMS) enhance flexibility by allowing rapid adjustments in hardware and software to meet changing product designs and volumes, unlike traditional mass production which emphasizes high-volume, inflexible output. RMS integrates modular components and scalable automation, optimizing both efficiency and customization for dynamic manufacturing environments.

Just-in-Sequence (JIS) Production

Just-in-Sequence (JIS) production enhances mass production efficiency by delivering components directly to the assembly line in the exact order of use, reducing inventory costs and minimizing work-in-progress. Flexible Manufacturing Systems complement JIS by enabling rapid adjustments to production sequences, supporting varied product customization without sacrificing the streamlined flow essential to JIS processes.

Lot Size One Manufacturing

Mass production excels at high-volume, standardized output but lacks adaptability for customized orders, making Lot Size One manufacturing more efficient within Flexible Manufacturing Systems that enable rapid product variation and minimal changeover times. Advanced automation and real-time data integration in Flexible Manufacturing Systems facilitate cost-effective single-unit production, meeting diverse customer demands without sacrificing speed or quality.

Agile Manufacturing Networks

Mass production emphasizes high-volume output with standardized processes, while flexible manufacturing systems (FMS) prioritize adaptability and efficiency through automated equipment and real-time data integration. Agile manufacturing networks leverage FMS to enable rapid response to market changes, optimize supply chain collaboration, and support customized production without sacrificing scale.

Cyber-Physical Production Systems (CPPS)

Cyber-Physical Production Systems (CPPS) integrate advanced IoT sensors, real-time data analytics, and adaptive automation to bridge the gap between mass production's high-volume efficiency and flexible manufacturing systems' customization capabilities. By enabling dynamic process adjustments and predictive maintenance, CPPS optimize production workflows, reduce downtime, and enhance product quality in modern industrial environments.

Plug-and-Produce Solutions

Plug-and-produce solutions in flexible manufacturing systems enable rapid integration of new equipment without extensive downtime, significantly enhancing production adaptability compared to traditional mass production lines. These systems leverage modular components and standardized interfaces, optimizing scalability and reducing time-to-market in dynamic manufacturing environments.

Mass Production vs Flexible Manufacturing Systems Infographic

industrydif.com

industrydif.com