Inventory management involves tracking stock levels, orders, and deliveries using periodic updates, which can lead to delays in identifying shortages or surpluses. Real-time inventory visibility offers continuous, up-to-the-minute insights into inventory status, enabling faster decision-making and reducing risks of stockouts or overstocking. Implementing real-time systems improves operational efficiency, enhances supply chain responsiveness, and supports just-in-time manufacturing practices.

Table of Comparison

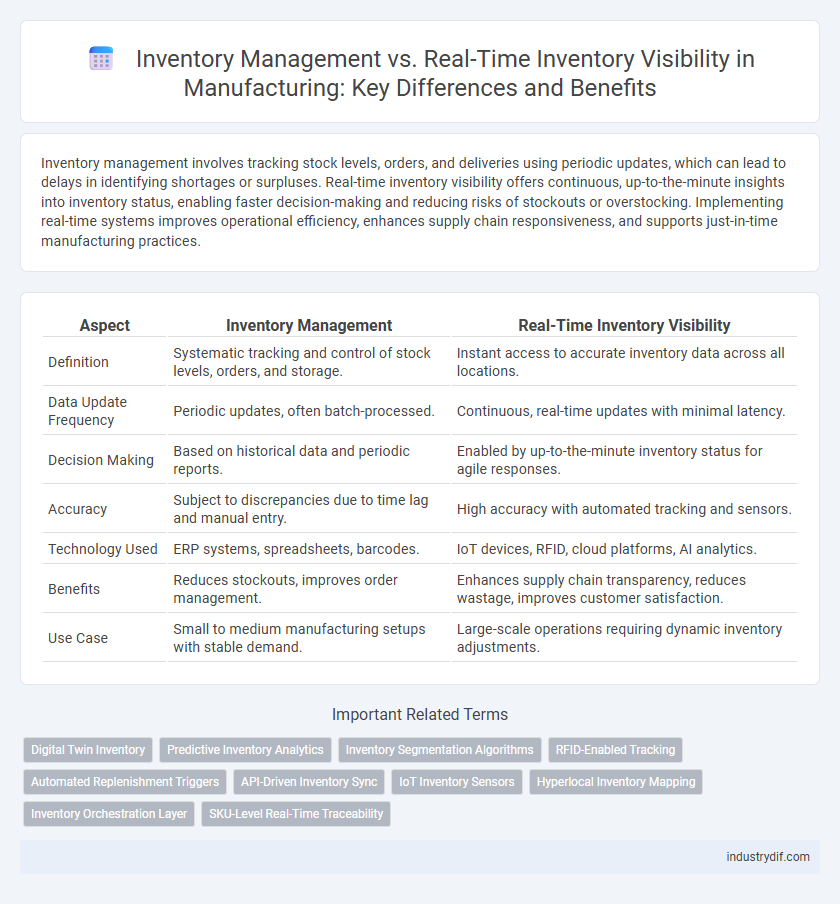

| Aspect | Inventory Management | Real-Time Inventory Visibility |

|---|---|---|

| Definition | Systematic tracking and control of stock levels, orders, and storage. | Instant access to accurate inventory data across all locations. |

| Data Update Frequency | Periodic updates, often batch-processed. | Continuous, real-time updates with minimal latency. |

| Decision Making | Based on historical data and periodic reports. | Enabled by up-to-the-minute inventory status for agile responses. |

| Accuracy | Subject to discrepancies due to time lag and manual entry. | High accuracy with automated tracking and sensors. |

| Technology Used | ERP systems, spreadsheets, barcodes. | IoT devices, RFID, cloud platforms, AI analytics. |

| Benefits | Reduces stockouts, improves order management. | Enhances supply chain transparency, reduces wastage, improves customer satisfaction. |

| Use Case | Small to medium manufacturing setups with stable demand. | Large-scale operations requiring dynamic inventory adjustments. |

Definition of Inventory Management

Inventory management involves the systematic process of ordering, storing, and using a company's inventory, including raw materials, components, and finished products. It ensures optimal stock levels to meet production demands while minimizing carrying costs and avoiding stockouts. Effective inventory management integrates demand forecasting, supplier coordination, and regular auditing to maintain operational efficiency and reduce waste.

Understanding Real-Time Inventory Visibility

Real-time inventory visibility enhances inventory management by providing up-to-the-minute data on stock levels, locations, and movement within the manufacturing process. This immediate insight reduces stockouts, minimizes excess inventory, and improves demand forecasting accuracy. Integration with IoT sensors and automated tracking systems enables manufacturers to achieve precise control over supply chain operations and production scheduling.

Key Differences Between Inventory Management and Real-Time Visibility

Inventory management involves tracking stock levels, orders, sales, and deliveries through periodic updates, whereas real-time inventory visibility provides instant, continuous data on inventory status across all locations. Key differences include the frequency of data updates, with inventory management often relying on batch processing and real-time visibility offering immediate access to inventory changes, enabling faster decision-making. Real-time visibility enhances accuracy and responsiveness in manufacturing operations by minimizing stockouts and overstock situations compared to traditional inventory management systems.

Benefits of Traditional Inventory Management Systems

Traditional inventory management systems offer structured control over stock levels through periodic audits and batch tracking, reducing the risk of overstocking and stockouts. These systems provide a solid foundation for forecasting demand and planning procurement cycles based on historical sales data. Their straightforward implementation and lower technological requirements make them cost-effective for businesses with stable inventory turnover rates.

Advantages of Real-Time Inventory Visibility Solutions

Real-time inventory visibility solutions provide accurate, up-to-the-minute data on stock levels, enabling manufacturers to reduce stockouts and overstock situations. These systems improve decision-making by integrating data from multiple locations, leading to enhanced operational efficiency and reduced carrying costs. Access to immediate inventory insights supports just-in-time manufacturing and faster response to market demand fluctuations.

Impact on Operational Efficiency

Inventory management systems organize and track stock levels, reducing errors and stockouts, which enhances operational efficiency by streamlining procurement and fulfillment processes. Real-time inventory visibility provides instant updates on inventory status across all locations, allowing for quicker decision-making and minimizing delays caused by inaccurate data. Together, these systems optimize supply chain responsiveness and resource allocation, driving significant improvements in manufacturing productivity and cost control.

Integration with Supply Chain Systems

Inventory management relies on periodic data updates, which can lead to discrepancies and delays in stock level information. Real-time inventory visibility integrates seamlessly with supply chain systems, providing instantaneous updates that enhance decision-making and operational efficiency. This integration enables synchronized demand forecasting, automated replenishment, and reduced stockouts across manufacturing processes.

Cost Implications and ROI Comparison

Inventory management systems optimize stock levels to reduce carrying costs and minimize stockouts, directly impacting overall manufacturing expenses. Real-time inventory visibility enhances decision-making accuracy, enabling faster response to demand fluctuations and lowering excess inventory costs, which increases ROI. Investing in real-time visibility solutions typically yields higher returns through improved operational efficiency and reduced financial risks compared to traditional inventory management methods.

Challenges in Implementing Real-Time Inventory Visibility

Challenges in implementing real-time inventory visibility in manufacturing include the integration of diverse legacy systems and IoT devices, which often lack standardized communication protocols. Data accuracy and synchronization across multiple locations present difficulties, leading to potential discrepancies and decision-making delays. High initial costs and the need for continuous maintenance and employee training also pose significant barriers to effective real-time inventory management.

Future Trends in Inventory Management Technologies

Inventory management is evolving with the integration of real-time inventory visibility, leveraging IoT sensors, AI-driven analytics, and blockchain for enhanced accuracy and transparency. Future trends emphasize automated replenishment systems, predictive demand forecasting, and cloud-based platforms to optimize inventory levels and reduce carrying costs. These technologies enable manufacturers to achieve just-in-time inventory, minimize stockouts, and improve overall supply chain responsiveness.

Related Important Terms

Digital Twin Inventory

Digital Twin Inventory leverages real-time data integration to create an accurate virtual replica of physical stock, enhancing inventory management by enabling immediate visibility and predictive analytics. This advanced approach reduces stockouts and overstock risks while optimizing supply chain efficiency through continuous synchronization between digital and physical assets.

Predictive Inventory Analytics

Predictive inventory analytics enhances real-time inventory visibility by using historical data and machine learning algorithms to forecast demand and optimize stock levels, reducing overstock and stockouts. Effective inventory management leverages these insights to streamline production schedules, minimize carrying costs, and improve supply chain responsiveness.

Inventory Segmentation Algorithms

Inventory segmentation algorithms enhance inventory management by categorizing stock based on demand patterns, turnover rates, and profitability, enabling more precise replenishment and reduced holding costs. Real-time inventory visibility leverages these algorithms to provide dynamic, up-to-date insights on stock levels across locations, optimizing supply chain responsiveness and minimizing stockouts.

RFID-Enabled Tracking

RFID-enabled tracking revolutionizes inventory management by providing real-time inventory visibility, eliminating manual counting errors and enabling instant stock level updates across manufacturing supply chains. This technology enhances demand forecasting accuracy, reduces stockouts, and optimizes warehouse operations through automated data capture and seamless integration with inventory management systems.

Automated Replenishment Triggers

Automated replenishment triggers in inventory management systems enable precise stock control by instantly updating inventory levels and initiating reorder processes based on real-time data, reducing stockouts and excess inventory. Leveraging real-time inventory visibility enhances decision-making by providing accurate, up-to-the-minute insights into product availability across all locations, improving supply chain responsiveness and operational efficiency.

API-Driven Inventory Sync

API-driven inventory sync enhances traditional inventory management by providing real-time inventory visibility, enabling manufacturers to update stock levels instantly across multiple sales channels and production systems. This seamless integration reduces discrepancies, improves order accuracy, and optimizes supply chain efficiency through automated, synchronized data exchange.

IoT Inventory Sensors

IoT inventory sensors enhance real-time inventory visibility by providing continuous, automated tracking of stock levels, reducing errors and minimizing stockouts. Unlike traditional inventory management systems that rely on periodic manual updates, IoT-enabled solutions deliver instant data analytics for optimized supply chain decision-making.

Hyperlocal Inventory Mapping

Hyperlocal inventory mapping enhances real-time inventory visibility by providing precise, location-based tracking of stock within manufacturing facilities, enabling efficient resource allocation and reducing lead times. Unlike traditional inventory management, this approach leverages IoT sensors and advanced analytics to deliver accurate, up-to-the-minute data on inventory levels, minimizing stockouts and overstock situations.

Inventory Orchestration Layer

The Inventory Orchestration Layer integrates data from multiple sources to optimize stock levels, reduce holding costs, and improve order fulfillment accuracy in manufacturing settings. Real-time inventory visibility enhances this process by providing up-to-the-minute data that supports dynamic decision-making and seamless synchronization between supply chain partners.

SKU-Level Real-Time Traceability

SKU-level real-time traceability enhances inventory management by providing precise, up-to-the-minute data on stock quantities and location, reducing errors and enabling faster decision-making. This granular visibility minimizes stockouts and overstock situations, optimizing supply chain efficiency and improving overall manufacturing productivity.

Inventory Management vs Real-Time Inventory Visibility Infographic

industrydif.com

industrydif.com