Traditional quality control relies heavily on manual inspection, which can be time-consuming and prone to human error. Machine vision inspection uses advanced cameras and AI algorithms to detect defects with higher accuracy and consistency. This technology enhances production efficiency by enabling real-time analysis and reducing the risk of defective products reaching customers.

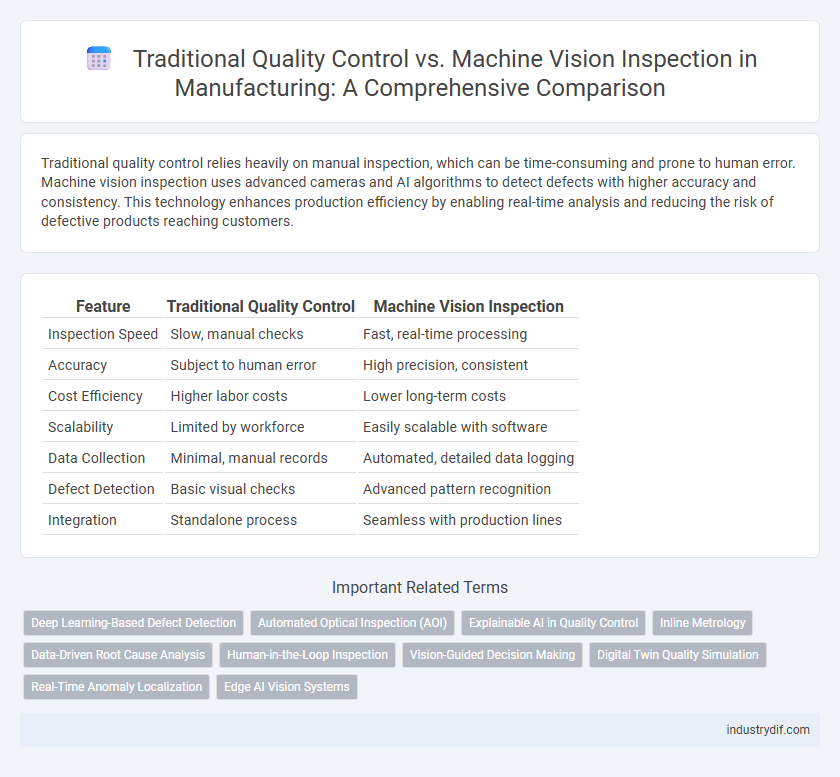

Table of Comparison

| Feature | Traditional Quality Control | Machine Vision Inspection |

|---|---|---|

| Inspection Speed | Slow, manual checks | Fast, real-time processing |

| Accuracy | Subject to human error | High precision, consistent |

| Cost Efficiency | Higher labor costs | Lower long-term costs |

| Scalability | Limited by workforce | Easily scalable with software |

| Data Collection | Minimal, manual records | Automated, detailed data logging |

| Defect Detection | Basic visual checks | Advanced pattern recognition |

| Integration | Standalone process | Seamless with production lines |

Introduction to Quality Control in Manufacturing

Quality control in manufacturing ensures that products meet specified standards and customer expectations through systematic inspection and testing. Traditional quality control relies on manual sampling and visual inspection, which can be time-consuming and prone to human error. Machine vision inspection automates defect detection using high-resolution cameras and AI algorithms, enhancing accuracy and efficiency in production lines.

Overview of Traditional Quality Control Methods

Traditional quality control methods in manufacturing rely heavily on manual inspection and measurement techniques to ensure product compliance with specifications. These processes involve trained inspectors performing visual checks, using gauges, calipers, and other physical measurement tools to detect defects or deviations. While effective, traditional methods tend to be time-consuming, prone to human error, and less efficient for high-volume production environments.

Fundamentals of Machine Vision Inspection

Machine vision inspection utilizes high-resolution cameras and advanced image processing algorithms to detect defects and deviations in manufacturing processes with precision and speed. Unlike traditional quality control methods relying on manual inspection, this technology enables consistent, real-time monitoring and analysis of product quality on the production line. Integration of machine vision systems enhances defect detection rates, reduces human error, and accelerates decision-making for quality assurance in manufacturing environments.

Key Differences Between Traditional and Machine Vision Approaches

Traditional Quality Control relies heavily on manual inspections, which can lead to variability in defect detection and slower throughput rates. Machine Vision Inspection employs automated cameras and AI algorithms to consistently identify defects with higher accuracy and faster processing speeds. Machine Vision systems also enable real-time data analysis and integration with manufacturing execution systems, enhancing traceability and process optimization.

Accuracy and Reliability: Manual Inspection vs. Automated Vision

Traditional quality control relies on manual inspection, which often suffers from human error and inconsistencies, leading to variable accuracy and reliability in defect detection. Machine vision inspection utilizes advanced cameras and artificial intelligence algorithms to deliver consistent, high-precision analysis, significantly reducing false positives and missed defects. Automated vision systems increase throughput and enable continuous monitoring, enhancing the overall quality assurance process compared to manual methods.

Speed and Throughput in Quality Assurance

Machine vision inspection significantly enhances speed and throughput in quality assurance by processing images and identifying defects in milliseconds, outperforming traditional quality control methods that rely on slower, manual inspections. Automated vision systems enable continuous, high-volume production line monitoring without fatigue, leading to increased throughput and consistent quality standards. This efficiency reduces downtime and accelerates decision-making, driving higher productivity in manufacturing environments.

Cost Implications: Labor vs. Automation Investments

Traditional quality control relies heavily on manual labor, resulting in high ongoing labor costs and susceptibility to human error. Machine vision inspection requires significant upfront investment in automation technology but reduces long-term expenses through consistent, high-speed defect detection and minimal labor requirements. Over time, automation offers considerable cost savings by lowering operational costs and improving production efficiency.

Scalability and Flexibility in Production Lines

Traditional quality control methods often struggle with scalability, as manual inspection becomes time-consuming and inconsistent when production volumes increase. Machine vision inspection offers enhanced flexibility by adapting quickly to different product types and inspection criteria through programmable algorithms and modular hardware. This technology enables manufacturers to maintain high accuracy and throughput across varying production scales, improving overall productivity and reducing operational costs.

Data Collection and Process Traceability

Traditional quality control relies on manual data collection, which is often prone to human error and limited traceability. Machine vision inspection enables automated, high-precision data capture in real time, enhancing process traceability and enabling comprehensive defect tracking. This shift allows manufacturers to implement more robust quality assurance protocols and improve overall production efficiency.

Future Trends: Integrating AI with Machine Vision Inspection

Integrating AI with machine vision inspection in manufacturing enhances defect detection accuracy by leveraging deep learning algorithms to identify complex patterns beyond human capability. Future trends highlight increased adoption of real-time data analytics and adaptive learning systems to continuously improve quality control processes. This combination drives higher efficiency, reduced operational costs, and proactive maintenance through predictive insights.

Related Important Terms

Deep Learning-Based Defect Detection

Deep learning-based defect detection leverages convolutional neural networks to identify complex patterns and anomalies in manufacturing processes, significantly outperforming traditional quality control methods that rely on manual inspection and rule-based algorithms. This approach enables real-time, high-precision defect detection with reduced human error and increased scalability across diverse industrial applications.

Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) leverages high-resolution cameras and image processing software to detect defects and inconsistencies in manufacturing lines faster and with higher accuracy than traditional quality control methods relying on manual inspection. Machine vision inspection systems minimize human error, increase throughput, and enable real-time monitoring, significantly improving overall product quality and reducing production costs in industries such as electronics and automotive manufacturing.

Explainable AI in Quality Control

Explainable AI in quality control enhances traditional manufacturing inspection by providing transparent decision-making processes, enabling operators to understand and trust automated defect detection in machine vision systems. This transparency improves fault diagnosis accuracy and reduces human error, leading to more consistent product quality and streamlined production workflows.

Inline Metrology

Traditional quality control relies on manual sampling and tactile measurements, which can be time-consuming and prone to human error, while machine vision inspection with inline metrology offers real-time, non-contact dimensional analysis using high-resolution cameras and AI algorithms. Inline metrology enhances production efficiency by providing continuous feedback for process adjustments, ensuring consistent product quality and reducing scrap rates in manufacturing environments.

Data-Driven Root Cause Analysis

Machine vision inspection enables real-time data collection and advanced analytics, facilitating precise root cause analysis by identifying defects and process variations more accurately than traditional quality control methods. This data-driven approach enhances manufacturing efficiency, reduces downtime, and supports continuous improvement by providing actionable insights derived from high-resolution images and automated pattern recognition.

Human-in-the-Loop Inspection

Human-in-the-loop inspection integrates machine vision systems with human expertise to enhance defect detection accuracy and decision-making efficiency in manufacturing quality control. This hybrid approach leverages automated image analysis for rapid screening while enabling skilled inspectors to evaluate ambiguous cases, reducing error rates and improving overall product reliability.

Vision-Guided Decision Making

Traditional quality control relies on manual inspection methods that are time-consuming and prone to human error, whereas machine vision inspection utilizes AI-driven cameras and algorithms to deliver rapid, objective, and highly accurate defect detection. Vision-guided decision making enhances manufacturing efficiency and consistency by enabling real-time analysis and automated corrective actions based on precise visual data.

Digital Twin Quality Simulation

Machine vision inspection enhances traditional quality control by integrating with digital twin quality simulation, enabling real-time defect detection and predictive analysis on virtual replicas of manufacturing processes. This fusion reduces inspection time, improves accuracy, and facilitates proactive adjustments, ensuring higher product quality and operational efficiency.

Real-Time Anomaly Localization

Machine vision inspection enables real-time anomaly localization with high precision by analyzing visual data instantly, surpassing the slower, subjective detection methods of traditional quality control. This technology reduces defect rates and increases production efficiency through automated, consistent monitoring and immediate identification of faults on manufacturing lines.

Edge AI Vision Systems

Edge AI vision systems revolutionize traditional quality control by enabling real-time defect detection and analysis directly on the manufacturing floor, significantly reducing latency and reliance on centralized processing. These systems leverage advanced machine learning algorithms embedded in edge devices to improve inspection accuracy, enhance throughput, and facilitate predictive maintenance in diverse industrial applications.

Traditional Quality Control vs Machine Vision Inspection Infographic

industrydif.com

industrydif.com