Shop floor control systems enable real-time monitoring and management of manufacturing operations, enhancing production efficiency through data collection and workflow optimization. Digital twins create virtual replicas of physical assets or processes, allowing manufacturers to simulate, predict, and optimize performance before implementing changes on the actual shop floor. Integrating digital twins with shop floor control provides a powerful synergy, improving decision-making accuracy and reducing downtime by anticipating issues before they impact production.

Table of Comparison

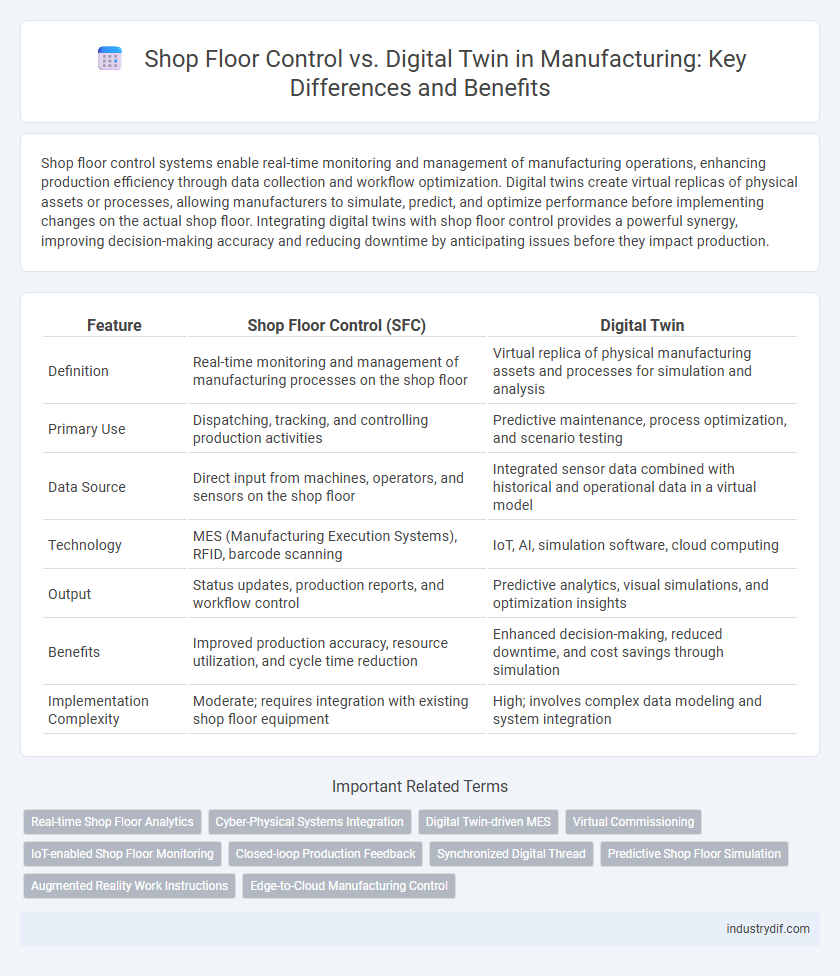

| Feature | Shop Floor Control (SFC) | Digital Twin |

|---|---|---|

| Definition | Real-time monitoring and management of manufacturing processes on the shop floor | Virtual replica of physical manufacturing assets and processes for simulation and analysis |

| Primary Use | Dispatching, tracking, and controlling production activities | Predictive maintenance, process optimization, and scenario testing |

| Data Source | Direct input from machines, operators, and sensors on the shop floor | Integrated sensor data combined with historical and operational data in a virtual model |

| Technology | MES (Manufacturing Execution Systems), RFID, barcode scanning | IoT, AI, simulation software, cloud computing |

| Output | Status updates, production reports, and workflow control | Predictive analytics, visual simulations, and optimization insights |

| Benefits | Improved production accuracy, resource utilization, and cycle time reduction | Enhanced decision-making, reduced downtime, and cost savings through simulation |

| Implementation Complexity | Moderate; requires integration with existing shop floor equipment | High; involves complex data modeling and system integration |

Introduction to Shop Floor Control and Digital Twin

Shop Floor Control (SFC) systems monitor and manage real-time production activities, optimizing workflow, resource allocation, and timely order completion on the manufacturing floor. Digital Twin technology creates a virtual replica of physical manufacturing processes, enabling simulation, predictive analytics, and enhanced decision-making. Integrating SFC with Digital Twin offers manufacturers improved operational visibility, reduced downtime, and accelerated response to production variances.

Key Differences Between Shop Floor Control and Digital Twin

Shop Floor Control (SFC) primarily focuses on real-time monitoring, scheduling, and management of manufacturing operations on the production floor, ensuring efficient task execution and resource allocation. In contrast, a Digital Twin creates a dynamic virtual replica of physical assets, processes, or systems, enabling simulation, analysis, and predictive maintenance to optimize production performance. Key differences lie in SFC's emphasis on operational control and workflow management, while Digital Twins provide comprehensive data integration and predictive insights for strategic decision-making.

Core Functions of Shop Floor Control Systems

Shop Floor Control systems primarily focus on monitoring, scheduling, and controlling production activities in real-time to optimize workflow and resource utilization. They track labor, machine status, and inventory levels to ensure timely execution and quality compliance on the manufacturing floor. Unlike Digital Twin technology that offers a virtual simulation of the entire production ecosystem, Shop Floor Control systems deliver hands-on operational management and immediate feedback for process adjustment.

Essential Features of Digital Twin Technology

Digital Twin technology in manufacturing integrates real-time data, simulation, and advanced analytics to create a dynamic virtual replica of physical shop floor operations. Essential features include predictive maintenance through continuous monitoring, process optimization using digital simulations, and enhanced decision-making powered by AI-driven insights. Compared to traditional Shop Floor Control, Digital Twin provides proactive control and deeper visibility into complex manufacturing systems.

Real-Time Data Collection and Analysis

Shop floor control systems enable real-time data collection directly from manufacturing equipment, enhancing immediate decision-making and operational efficiency. Digital twins utilize this real-time data to create dynamic virtual replicas of the shop floor, allowing for advanced simulation, predictive maintenance, and optimized resource allocation. Integration of these technologies improves overall production transparency and reduces downtime by leveraging continuous data analysis.

Integration with Manufacturing Execution Systems (MES)

Shop Floor Control systems provide real-time monitoring and management of production activities, enabling direct interaction with Manufacturing Execution Systems (MES) to optimize workflow and reduce downtime. Digital Twins offer a virtual replica of the manufacturing environment, allowing seamless integration with MES to simulate, analyze, and improve processes before physical implementation. Combining Shop Floor Control and Digital Twin integration with MES enhances decision-making, increases operational efficiency, and ensures synchronized production across all manufacturing stages.

Impact on Production Efficiency and Quality

Shop Floor Control systems provide real-time monitoring and management of production activities, enabling immediate response to disruptions and optimizing workflow efficiency. Digital Twin technology simulates physical assets and processes, allowing predictive analysis and proactive quality improvements before actual production. Integrating both enhances production efficiency by combining real-time operational control with advanced data-driven insights for superior quality assurance.

Scalability and Flexibility in Modern Manufacturing

Shop floor control systems provide real-time monitoring and management of production activities, enhancing operational scalability by streamlining workflows and reducing downtime. Digital twins offer a flexible virtual replica of manufacturing processes, enabling dynamic adjustments and predictive analysis to optimize scalability across different production scenarios. Integrating both technologies maximizes manufacturing adaptability, supporting rapid scaling and customization to meet evolving market demands.

Implementation Challenges and Considerations

Implementing Shop Floor Control (SFC) systems requires overcoming challenges such as real-time data integration from diverse machines, ensuring operator training, and maintaining system reliability to avoid production disruptions. Digital Twin technology demands high-quality, real-time sensor data, significant computational resources for accurate virtual modeling, and seamless integration with existing Enterprise Resource Planning (ERP) systems. Both approaches necessitate robust cybersecurity measures and scalable IT infrastructure to support ongoing data processing and analytics in complex manufacturing environments.

Future Trends: Shop Floor Control vs Digital Twin

Future trends in manufacturing emphasize the integration of Shop Floor Control systems with Digital Twin technology to enhance real-time monitoring, predictive maintenance, and process optimization. Digital Twins enable virtual replication of physical assets and workflows, allowing manufacturers to simulate production scenarios and anticipate issues before they occur. Shop Floor Control evolves by leveraging these simulations to improve decision-making, increase agility, and drive Industry 4.0 transformation.

Related Important Terms

Real-time Shop Floor Analytics

Real-time shop floor analytics leverage Digital Twin technology to create dynamic virtual models of manufacturing processes, enabling precise monitoring and optimization of production activities. Unlike traditional Shop Floor Control systems that rely on static data, Digital Twins provide continuous data integration and predictive insights, enhancing operational efficiency and reducing downtime.

Cyber-Physical Systems Integration

Shop Floor Control systems enable real-time monitoring and management of manufacturing processes, while Digital Twins provide a virtual replica to simulate, predict, and optimize cyber-physical systems integration. Combining these technologies enhances operational efficiency, reduces downtime, and improves decision-making through synchronized data exchange between physical assets and their digital counterparts.

Digital Twin-driven MES

Digital Twin-driven MES leverages real-time simulation and data integration to optimize shop floor control, enhancing production efficiency, predictive maintenance, and resource allocation. By creating a virtual replica of the manufacturing process, it enables precise monitoring, rapid decision-making, and continuous process improvement beyond traditional shop floor control methods.

Virtual Commissioning

Shop floor control systems manage real-time production activities, optimizing workflows and resource allocation on the manufacturing floor, while digital twins enable virtual commissioning by creating precise virtual replicas of machines and processes to simulate and validate operations before physical deployment. Virtual commissioning with digital twins reduces downtime, minimizes errors, and accelerates system integration compared to traditional shop floor control methods.

IoT-enabled Shop Floor Monitoring

IoT-enabled Shop Floor Monitoring integrates real-time sensor data for enhanced Shop Floor Control, enabling precise tracking of equipment performance, production status, and workflow optimization. Digital Twin technology complements this by creating virtual replicas of manufacturing processes, facilitating predictive maintenance and scenario simulations to improve operational efficiency.

Closed-loop Production Feedback

Shop floor control systems provide real-time data on production processes, enabling immediate adjustments to optimize efficiency, while digital twins simulate entire manufacturing setups for predictive analysis and strategic planning. Closed-loop production feedback integrates shop floor data with digital twin models to continuously refine operations, improve quality, and reduce downtime through precise, data-driven decision-making.

Synchronized Digital Thread

Shop Floor Control systems enable real-time monitoring and coordination of manufacturing activities, while Digital Twin technology creates a virtual replica of physical assets and processes for advanced analysis and optimization. Integrating these through a synchronized digital thread ensures seamless data flow and traceability across the production lifecycle, enhancing decision-making and operational efficiency.

Predictive Shop Floor Simulation

Shop Floor Control systems enhance manufacturing efficiency by monitoring real-time production data, while Digital Twin technology enables predictive shop floor simulation through virtual replicas that analyze potential process variations and optimize workflows before physical implementation. Integrating Digital Twins with Shop Floor Control facilitates proactive decision-making, reduces downtime, and improves resource allocation by forecasting production outcomes and identifying bottlenecks.

Augmented Reality Work Instructions

Augmented Reality work instructions enhance shop floor control by overlaying real-time, interactive guidance directly onto machinery, reducing errors and improving operator efficiency. Integrating digital twin technology enables dynamic simulations and immediate updates to AR instructions, ensuring precise adherence to manufacturing processes and minimizing downtime.

Edge-to-Cloud Manufacturing Control

Shop floor control systems enable real-time production monitoring and operational decision-making by collecting data directly from machines and operators, ensuring efficient workflow management at the edge. Digital twins extend this capability by creating dynamic virtual replicas of manufacturing processes that leverage edge-to-cloud integration for predictive analytics, allowing for proactive maintenance and optimized production scheduling across distributed facilities.

Shop Floor Control vs Digital Twin Infographic

industrydif.com

industrydif.com