Kaizen emphasizes small, incremental changes driven by employee involvement to enhance manufacturing processes, fostering a culture of continuous, sustainable improvement. Continuous Improvement 4.0 integrates advanced digital technologies like IoT, AI, and data analytics to accelerate process optimization, enabling real-time decision-making and predictive maintenance. Together, Kaizen and Continuous Improvement 4.0 create a powerful synergy by combining human-centric practices with Industry 4.0 innovations for superior manufacturing efficiency.

Table of Comparison

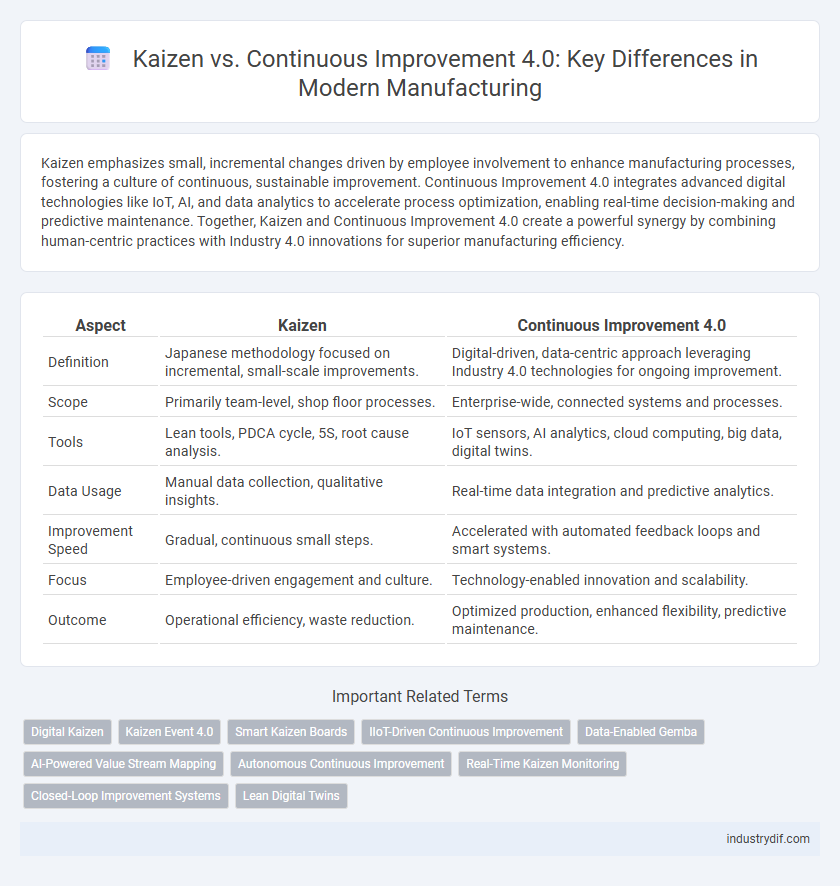

| Aspect | Kaizen | Continuous Improvement 4.0 |

|---|---|---|

| Definition | Japanese methodology focused on incremental, small-scale improvements. | Digital-driven, data-centric approach leveraging Industry 4.0 technologies for ongoing improvement. |

| Scope | Primarily team-level, shop floor processes. | Enterprise-wide, connected systems and processes. |

| Tools | Lean tools, PDCA cycle, 5S, root cause analysis. | IoT sensors, AI analytics, cloud computing, big data, digital twins. |

| Data Usage | Manual data collection, qualitative insights. | Real-time data integration and predictive analytics. |

| Improvement Speed | Gradual, continuous small steps. | Accelerated with automated feedback loops and smart systems. |

| Focus | Employee-driven engagement and culture. | Technology-enabled innovation and scalability. |

| Outcome | Operational efficiency, waste reduction. | Optimized production, enhanced flexibility, predictive maintenance. |

Introduction to Kaizen and Continuous Improvement 4.0

Kaizen, a Japanese philosophy emphasizing incremental, continuous improvements through employee involvement, enhances manufacturing efficiency and reduces waste. Continuous Improvement 4.0 integrates advanced Industry 4.0 technologies like IoT, AI, and big data analytics to accelerate process optimization and real-time decision-making. Combining traditional Kaizen principles with digital transformation drives agile, data-driven manufacturing excellence.

Historical Evolution: Kaizen and Its Foundations

Kaizen, originating in post-World War II Japan, laid the foundation for continuous improvement by emphasizing small, incremental changes driven by employee involvement and standardized processes. Rooted in Total Quality Management and Lean principles, it promotes a culture of ongoing enhancement and waste reduction. Continuous Improvement 4.0 builds on Kaizen's legacy by integrating advanced digital technologies such as IoT, AI, and data analytics to accelerate and optimize manufacturing processes in the Industry 4.0 era.

Overview of Continuous Improvement 4.0

Continuous Improvement 4.0 integrates advanced digital technologies such as IoT, AI, and big data analytics to enhance manufacturing processes, promoting real-time monitoring and data-driven decision-making. This approach builds on traditional Kaizen principles by emphasizing automation, predictive maintenance, and smart factory implementations, resulting in higher efficiency and reduced operational costs. Continuous Improvement 4.0 drives sustainable competitiveness through adaptive process optimization and seamless human-machine collaboration in Industry 4.0 environments.

Key Principles: Kaizen Methodology

Kaizen methodology emphasizes incremental, employee-driven improvements centered on the principles of standardization, waste elimination, and root cause analysis. It fosters a culture of ongoing small changes that collectively enhance productivity and quality without large capital investments. Unlike Continuous Improvement 4.0, which integrates advanced digital tools and data analytics, Kaizen relies on direct workforce engagement and simple, systematic problem-solving techniques.

Core Concepts of Continuous Improvement 4.0

Continuous Improvement 4.0 integrates advanced digital technologies such as IoT, AI, and big data analytics to enhance manufacturing processes by enabling real-time monitoring and predictive maintenance. Unlike traditional Kaizen, which relies on incremental employee-driven changes, Continuous Improvement 4.0 leverages automation and smart systems to accelerate decision-making and optimize operations. Core concepts include data-driven insights, seamless connectivity, and adaptive feedback loops that foster agility and operational excellence in Industry 4.0 environments.

Technology Integration: Industry 4.0 in Continuous Improvement

Continuous Improvement 4.0 leverages Industry 4.0 technologies such as IoT, AI, and big data analytics to enhance manufacturing processes by enabling real-time monitoring, predictive maintenance, and data-driven decision-making. Unlike traditional Kaizen, which emphasizes incremental human-driven improvements, Continuous Improvement 4.0 integrates digital tools to automate workflows and optimize efficiency at scale. This technology integration drives more agile and adaptive production systems, resulting in increased productivity and reduced waste.

Benefits and Outcomes in Modern Manufacturing

Kaizen emphasizes incremental, employee-driven improvements fostering a culture of continuous, small-scale enhancements, while Continuous Improvement 4.0 integrates advanced digital technologies such as IoT, AI, and data analytics for dynamic, real-time optimization. The benefits of Kaizen include enhanced team collaboration, waste reduction, and steady quality improvements, whereas Continuous Improvement 4.0 delivers accelerated decision-making, predictive maintenance, and greater agility in production processes. Modern manufacturing leveraging these approaches achieves higher operational efficiency, reduced downtime, and sustained competitive advantage through both human-centric and technology-driven innovation.

Challenges in Adopting Kaizen vs Continuous Improvement 4.0

Challenges in adopting Kaizen stem from its reliance on cultural change and employee engagement in traditional manufacturing environments, which can be resistant to new practices. Continuous Improvement 4.0 faces obstacles integrating advanced digital technologies like IoT, AI, and big data analytics with legacy systems, requiring substantial investment and technical expertise. Both approaches demand sustained commitment but differ in scalability and adaptation to Industry 4.0's fast-paced innovation cycles.

Case Studies: Real-World Applications

Kaizen emphasizes incremental daily improvements driven by employee involvement, demonstrated in Toyota's production system which reduced waste and improved efficiency significantly. Continuous Improvement 4.0 integrates advanced technologies such as IoT, AI, and big data analytics, enabling companies like Siemens to achieve predictive maintenance and real-time process optimization. Case studies reveal that blending traditional Kaizen principles with digital tools leads to superior operational performance and sustainable competitive advantage.

Future Trends in Manufacturing Improvements

Kaizen emphasizes incremental, small-scale improvements driven by employee participation, while Continuous Improvement 4.0 integrates advanced technologies such as AI, IoT, and big data analytics to enable real-time, data-driven manufacturing optimizations. Future trends in manufacturing improvements will increasingly leverage digital twins, predictive maintenance, and augmented reality to enhance process efficiency and quality control. The convergence of traditional Kaizen principles with Industry 4.0 technologies is poised to create a hybrid approach, maximizing operational agility and sustainability in smart factories.

Related Important Terms

Digital Kaizen

Digital Kaizen integrates IoT, AI, and real-time data analytics to enhance traditional Kaizen processes, driving faster iterations and adaptive problem-solving in manufacturing. Continuous Improvement 4.0 extends this by leveraging smart automation and advanced machine learning to enable predictive maintenance and holistic operational efficiency.

Kaizen Event 4.0

Kaizen Event 4.0 integrates digital technologies like IoT, AI, and big data analytics to accelerate real-time problem-solving and process optimization in manufacturing environments. This evolution of traditional Kaizen emphasizes rapid, data-driven improvements aligned with Industry 4.0 principles, enhancing efficiency, quality, and workforce engagement.

Smart Kaizen Boards

Smart Kaizen Boards enhance manufacturing efficiency by integrating real-time data analytics and IoT connectivity, enabling more precise tracking of continuous improvement 4.0 initiatives. These digital platforms streamline Kaizen processes through automated performance metrics, fostering rapid problem-solving and sustained operational excellence.

IIoT-Driven Continuous Improvement

IIoT-driven Continuous Improvement 4.0 leverages real-time data from interconnected manufacturing devices to identify inefficiencies and optimize processes faster than traditional Kaizen methods, which rely on incremental, employee-led changes. Advanced analytics and machine learning within IIoT frameworks enable predictive maintenance and adaptive production adjustments, significantly enhancing productivity and reducing downtime in smart factories.

Data-Enabled Gemba

Kaizen emphasizes incremental improvements driven by frontline employees, while Continuous Improvement 4.0 integrates advanced data analytics and IoT technologies to enable real-time, data-enabled Gemba walks that identify inefficiencies and optimize manufacturing processes. Leveraging sensor data and digital twins, Continuous Improvement 4.0 enhances decision-making accuracy, accelerates problem-solving, and fosters a culture of proactive operational excellence.

AI-Powered Value Stream Mapping

Kaizen emphasizes incremental, employee-driven improvements focused on waste reduction, while Continuous Improvement 4.0 integrates AI-powered value stream mapping to analyze real-time production data, identify bottlenecks, and optimize workflows dynamically. Leveraging machine learning algorithms, AI enhances predictive maintenance, reduces downtime, and accelerates the decision-making process for smarter manufacturing operations.

Autonomous Continuous Improvement

Autonomous Continuous Improvement in Manufacturing 4.0 integrates AI-driven analytics and real-time data feedback loops to enable machines and systems to self-optimize production processes without human intervention. Unlike traditional Kaizen, which relies on incremental employee-led improvements, Autonomous Continuous Improvement leverages advanced automation and IoT connectivity to achieve faster, adaptive, and scalable operational enhancements.

Real-Time Kaizen Monitoring

Real-Time Kaizen Monitoring leverages IoT sensors and AI analytics to identify inefficiencies instantly, enabling immediate corrective actions within manufacturing processes. Continuous Improvement 4.0 integrates these technologies to create dynamic feedback loops, enhancing productivity and minimizing downtime compared to traditional Kaizen methods.

Closed-Loop Improvement Systems

Kaizen emphasizes incremental, employee-driven improvements within a structured daily routine, while Continuous Improvement 4.0 integrates advanced digital technologies and real-time data analytics to enable Closed-Loop Improvement Systems that accelerate feedback cycles and enhance decision-making accuracy. Closed-Loop Improvement Systems leverage IoT sensors, AI algorithms, and machine learning to continuously monitor manufacturing processes, automatically identify inefficiencies, and implement corrective actions, driving superior operational performance and reducing downtime.

Lean Digital Twins

Kaizen emphasizes incremental, employee-driven improvements, while Continuous Improvement 4.0 leverages Lean Digital Twins to simulate and optimize manufacturing processes in real-time, enhancing operational efficiency and reducing waste. Integrating Lean Digital Twins enables data-driven decision-making and predictive analysis, transforming traditional Kaizen practices into a smart, agile manufacturing strategy.

Kaizen vs Continuous Improvement 4.0 Infographic

industrydif.com

industrydif.com