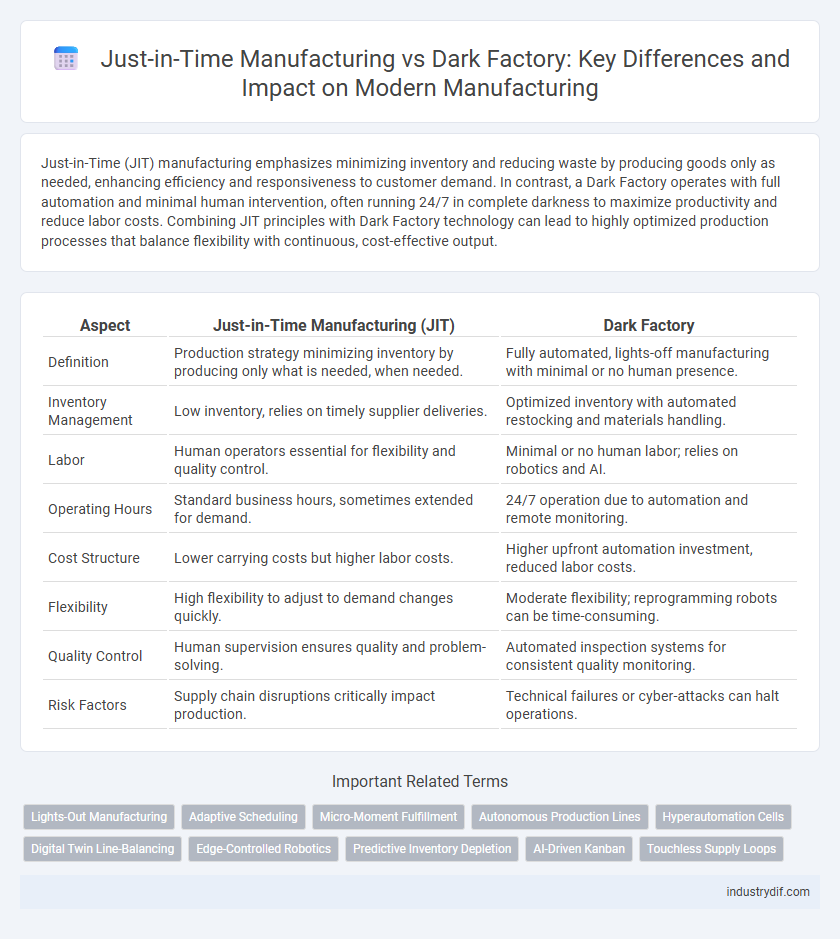

Just-in-Time (JIT) manufacturing emphasizes minimizing inventory and reducing waste by producing goods only as needed, enhancing efficiency and responsiveness to customer demand. In contrast, a Dark Factory operates with full automation and minimal human intervention, often running 24/7 in complete darkness to maximize productivity and reduce labor costs. Combining JIT principles with Dark Factory technology can lead to highly optimized production processes that balance flexibility with continuous, cost-effective output.

Table of Comparison

| Aspect | Just-in-Time Manufacturing (JIT) | Dark Factory |

|---|---|---|

| Definition | Production strategy minimizing inventory by producing only what is needed, when needed. | Fully automated, lights-off manufacturing with minimal or no human presence. |

| Inventory Management | Low inventory, relies on timely supplier deliveries. | Optimized inventory with automated restocking and materials handling. |

| Labor | Human operators essential for flexibility and quality control. | Minimal or no human labor; relies on robotics and AI. |

| Operating Hours | Standard business hours, sometimes extended for demand. | 24/7 operation due to automation and remote monitoring. |

| Cost Structure | Lower carrying costs but higher labor costs. | Higher upfront automation investment, reduced labor costs. |

| Flexibility | High flexibility to adjust to demand changes quickly. | Moderate flexibility; reprogramming robots can be time-consuming. |

| Quality Control | Human supervision ensures quality and problem-solving. | Automated inspection systems for consistent quality monitoring. |

| Risk Factors | Supply chain disruptions critically impact production. | Technical failures or cyber-attacks can halt operations. |

Introduction to Just-in-Time Manufacturing and Dark Factory

Just-in-Time (JIT) Manufacturing is a production strategy that minimizes inventory by delivering materials precisely when needed, reducing waste and enhancing efficiency. Dark Factory refers to fully automated manufacturing facilities that operate without human presence, utilizing robotics and AI for continuous production. Both methods aim to optimize manufacturing efficiency but differ significantly in operational approach and technological integration.

Core Principles of Just-in-Time Manufacturing

Just-in-Time Manufacturing centers on minimizing inventory by producing goods only as they are needed, reducing waste and increasing efficiency. It relies heavily on precise demand forecasting, streamlined supply chain coordination, and continuous improvement to align production closely with customer demand. This methodology contrasts with Dark Factories, which emphasize automation and minimal human intervention for uninterrupted operations.

Fundamental Concepts Behind Dark Factory Operations

Dark factory operations leverage fully automated systems operating without human presence, optimizing production efficiency and reducing labor costs. Unlike just-in-time manufacturing, which focuses on minimizing inventory and synchronizing supply chains, dark factories emphasize continuous, 24/7 operation through robotics and AI-driven machinery. Key concepts include autonomous equipment management, real-time monitoring through IoT sensors, and predictive maintenance to ensure uninterrupted workflows in manufacturing processes.

Key Technological Enablers for Just-in-Time Systems

Just-in-Time (JIT) manufacturing relies heavily on real-time data analytics, automated inventory management, and advanced robotics to streamline production and reduce waste. Internet of Things (IoT) sensors and integrated supply chain software enable precise demand forecasting and seamless coordination between suppliers and manufacturers. These technological enablers contrast with Dark Factory automation, which emphasizes fully autonomous operations with minimal human intervention.

Automation and Robotics in Dark Factory Manufacturing

Dark factory manufacturing leverages advanced automation and robotics to operate without human intervention, enabling continuous, 24/7 production with minimal error rates and enhanced efficiency. Unlike Just-in-Time manufacturing, which depends on precise inventory management and human coordination to reduce waste, dark factories utilize autonomous systems for real-time monitoring, predictive maintenance, and adaptive production processes. This shift toward fully automated environments minimizes labor costs and optimizes resource utilization, ultimately accelerating manufacturing cycles and improving product consistency.

Efficiency Metrics: Comparing JIT and Dark Factories

Just-in-Time (JIT) manufacturing excels in reducing inventory costs and minimizing waste by synchronizing production closely with demand, leading to high inventory turnover rates and shorter lead times. Dark factories leverage automation and AI to operate 24/7 without human intervention, significantly increasing machine utilization rates and labor efficiency. Comparing efficiency metrics, JIT reduces operational expenses through demand-driven workflows, while dark factories enhance throughput and consistency, offering superior scalability in high-volume production environments.

Inventory Management Differences: JIT vs Dark Factory

Just-in-Time (JIT) manufacturing emphasizes minimizing inventory by receiving materials only as they are needed in the production process, drastically reducing storage costs and waste. In contrast, a Dark Factory operates with fully automated systems and robotics, enabling continuous production with minimal human intervention and often maintaining higher inventory levels through predictive stocking to ensure uninterrupted workflow. The inventory management in JIT relies heavily on precise supplier coordination, whereas Dark Factory inventory management integrates advanced sensors and AI for real-time stock monitoring and replenishment.

Workforce Implications and Skill Requirements

Just-in-time manufacturing relies heavily on a flexible, skilled workforce capable of quick adjustments to production schedules, emphasizing collaboration and real-time problem-solving skills. In contrast, dark factories operate with minimal human presence, requiring fewer operators but a workforce with advanced technical skills in automation, robotics, and system maintenance to ensure uninterrupted, autonomous production. Both models necessitate continuous upskilling, but the dark factory shifts focus towards high-level digital proficiency and remote monitoring capabilities.

Risk Factors and Mitigation Strategies

Just-in-Time (JIT) manufacturing faces risks such as supply chain disruptions and demand variability, which can lead to production delays and inventory shortages. Dark factories mitigate risks of labor dependency and operational costs by utilizing automated systems for continuous operations but face challenges related to system malfunctions and cybersecurity threats. Effective strategies include diversifying suppliers and implementing predictive analytics for JIT, while dark factories require robust maintenance protocols and advanced cybersecurity measures to ensure uninterrupted performance.

Future Trends in Manufacturing: Integrating JIT and Dark Factory Approaches

Future manufacturing trends emphasize integrating Just-in-Time (JIT) strategies with Dark Factory automation to enhance efficiency and reduce operational costs. By combining JIT's inventory minimization with fully automated, sensor-driven Dark Factories, manufacturers achieve real-time responsiveness and continuous production without human intervention. This fusion supports agile supply chains, predictive maintenance, and sustainable resource management essential for Industry 4.0 advancements.

Related Important Terms

Lights-Out Manufacturing

Just-in-time manufacturing minimizes inventory costs by synchronizing production closely with demand, enhancing efficiency and reducing waste. Lights-out manufacturing, a key feature of dark factories, leverages fully automated processes and robotics to operate without human intervention, maximizing uptime and reducing labor expenses.

Adaptive Scheduling

Just-in-Time (JIT) manufacturing relies on adaptive scheduling to minimize inventory costs by synchronizing production closely with demand, enhancing efficiency and reducing waste. In contrast, dark factories employ advanced adaptive scheduling algorithms integrated with automation and AI to maintain continuous, unattended production, optimizing throughput and machine utilization without human intervention.

Micro-Moment Fulfillment

Just-in-Time (JIT) manufacturing emphasizes precise inventory control and minimal waste by producing goods only as needed, enhancing micro-moment fulfillment through timely resource allocation and real-time demand responsiveness. In contrast, Dark Factories leverage full automation and AI-driven processes to operate continuously without human intervention, enabling ultra-fast micro-moment fulfillment by accelerating production cycles and reducing human-induced delays.

Autonomous Production Lines

Just-in-Time manufacturing minimizes inventory and enhances efficiency by synchronizing production schedules with demand, while dark factories leverage fully autonomous production lines operating without human presence to maximize precision and reduce labor costs. Autonomous production lines integrate AI-driven robotics and IoT sensors to enable real-time monitoring, adaptive control, and seamless material handling, driving higher productivity and consistent quality in both manufacturing models.

Hyperautomation Cells

Hyperautomation cells in just-in-time manufacturing streamline production by integrating AI, robotics, and IoT sensors to reduce waste and enhance scheduling precision. In contrast, dark factory setups leverage hyperautomation cells operating autonomously in fully automated environments without human presence, maximizing operational efficiency and minimizing downtime.

Digital Twin Line-Balancing

Just-in-Time Manufacturing relies on precise inventory control and synchronized workflows to minimize waste, while Dark Factories utilize fully automated systems operating without human intervention, maximizing efficiency and reducing labor costs. Digital Twin Line-Balancing enhances both approaches by creating virtual models that simulate production processes in real-time, enabling dynamic adjustments to optimize throughput and resource allocation.

Edge-Controlled Robotics

Edge-controlled robotics in Just-in-Time (JIT) manufacturing enhances precision and reduces latency by processing data locally, enabling rapid adaptation to production changes and minimizing downtime. In contrast, Dark Factories leverage edge robotics for fully autonomous operations without human presence, optimizing efficiency and scalability through continuous, real-time control and monitoring of manufacturing processes.

Predictive Inventory Depletion

Just-in-Time Manufacturing relies on precise demand forecasting to minimize inventory holding costs but remains vulnerable to supply chain disruptions affecting inventory levels. Dark Factories utilize advanced automation and real-time data analytics, enabling predictive inventory depletion with higher accuracy and reduced human error, ensuring continuous production flow.

AI-Driven Kanban

AI-driven Kanban systems in Just-in-Time manufacturing optimize inventory management by predicting demand patterns and automating replenishment processes, significantly reducing waste and production delays. In contrast, Dark Factories leverage AI-driven Kanban to maintain uninterrupted operations with minimal human intervention, enhancing efficiency and operational resilience through real-time data analytics and autonomous decision-making.

Touchless Supply Loops

Just-in-Time manufacturing emphasizes minimizing inventory through precise scheduling and supplier coordination, while Dark Factory leverages full automation and AI-driven systems to operate without human intervention. Touchless supply loops in Dark Factories enhance efficiency and reduce errors by integrating robotics, IoT sensors, and AI analytics to autonomously manage material flow and production schedules.

Just-in-Time Manufacturing vs Dark Factory Infographic

industrydif.com

industrydif.com