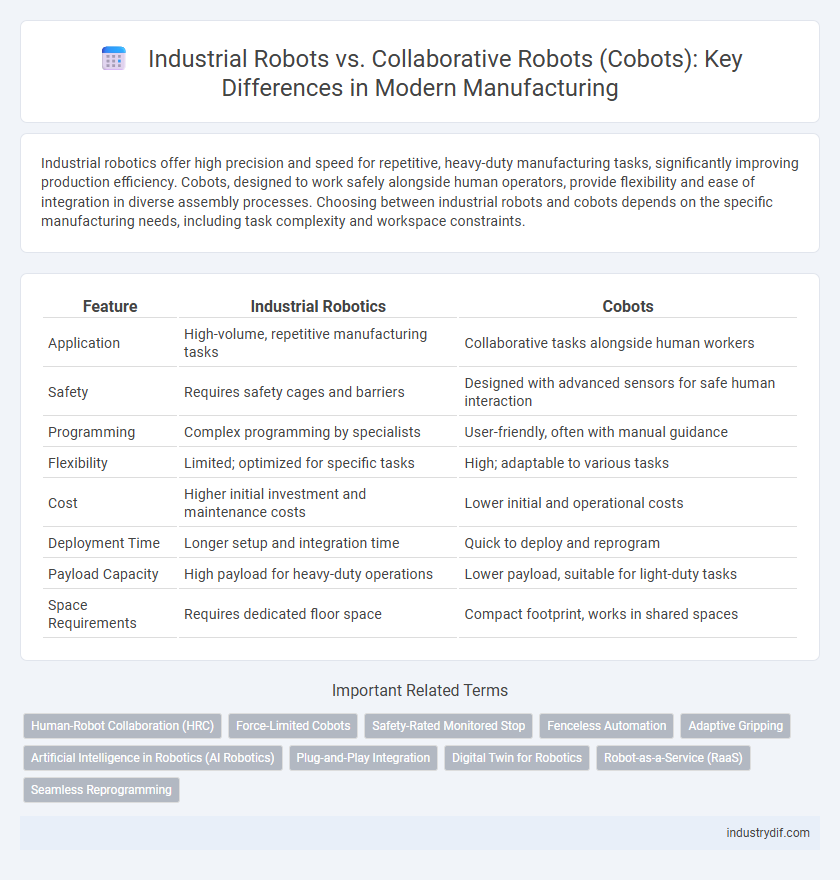

Industrial robotics offer high precision and speed for repetitive, heavy-duty manufacturing tasks, significantly improving production efficiency. Cobots, designed to work safely alongside human operators, provide flexibility and ease of integration in diverse assembly processes. Choosing between industrial robots and cobots depends on the specific manufacturing needs, including task complexity and workspace constraints.

Table of Comparison

| Feature | Industrial Robotics | Cobots |

|---|---|---|

| Application | High-volume, repetitive manufacturing tasks | Collaborative tasks alongside human workers |

| Safety | Requires safety cages and barriers | Designed with advanced sensors for safe human interaction |

| Programming | Complex programming by specialists | User-friendly, often with manual guidance |

| Flexibility | Limited; optimized for specific tasks | High; adaptable to various tasks |

| Cost | Higher initial investment and maintenance costs | Lower initial and operational costs |

| Deployment Time | Longer setup and integration time | Quick to deploy and reprogram |

| Payload Capacity | High payload for heavy-duty operations | Lower payload, suitable for light-duty tasks |

| Space Requirements | Requires dedicated floor space | Compact footprint, works in shared spaces |

Definition and Overview: Industrial Robots vs Cobots

Industrial robots are autonomous machines designed for large-scale, repetitive manufacturing tasks that require high precision and speed, often operating within fenced environments to ensure safety. Cobots, or collaborative robots, are engineered to work safely alongside human operators, featuring advanced sensors and adaptable programming for flexible, low-volume production processes. While industrial robots excel in heavy-duty, high-speed automation, cobots prioritize human-robot interaction and ease of integration in dynamic manufacturing settings.

Key Technological Differences

Industrial robotics feature high precision, robust automation capabilities, and operate independently in structured environments, often performing repetitive tasks with minimal human intervention. Cobots, or collaborative robots, are designed with advanced sensors and AI to safely work alongside humans, emphasizing flexibility, ease of programming, and adaptive interactions. Key technological differences include safety mechanisms like force-limited joints in cobots versus heavy-duty construction in industrial robots, and communication protocols optimized for real-time human collaboration.

Safety Considerations in Robotics Deployment

Industrial robotics prioritize high-speed, repetitive tasks in segregated environments with extensive safety barriers to prevent human interaction, minimizing injury risk. Cobots integrate advanced sensors, force limiters, and collaborative safety standards such as ISO/TS 15066, enabling safe operation alongside humans without physical barriers. Implementing risk assessments, emergency stop mechanisms, and regular maintenance is critical to ensure compliant and safe deployment in both industrial robots and cobots.

Flexibility and Adaptability in Manufacturing Environments

Industrial robotics offer high precision and speed but often lack the flexibility required for varied or small-batch manufacturing processes. Cobots, designed to work alongside human operators, provide greater adaptability by easily reprogramming for multiple tasks and quickly integrating into existing workflows. This flexibility in cobots supports dynamic production environments, enabling faster changeovers and customized manufacturing without extensive downtime.

Programming and User Interface Comparisons

Industrial robotics systems often require specialized programming languages like RAPID or KUKA KRL, demanding advanced coding skills and extensive training. Cobots feature intuitive user interfaces with graphical programming and teach-by-demonstration capabilities, enabling operators without programming expertise to customize tasks easily. The simplified programming environment of cobots reduces downtime and accelerates deployment compared to the complex and time-intensive programming of traditional industrial robots.

Cost Analysis: Initial Investment and ROI

Industrial robotics typically require a higher initial investment, often costing between $100,000 and $150,000 per unit, whereas cobots range from $20,000 to $50,000, making them more accessible for small to medium enterprises. Return on investment (ROI) for industrial robots usually occurs over 2 to 4 years due to their high throughput and automation capabilities, while cobots offer faster ROI within 12 to 18 months by improving productivity with lower upfront costs and easier integration. Cost analysis must consider not only purchase price but also maintenance, programming, and operational expenses to determine the optimal automation solution based on production scale and complexity.

Applications in Modern Manufacturing

Industrial robotics in modern manufacturing excels in high-volume, repetitive tasks such as welding, painting, and assembly, offering precision and speed crucial for automotive and electronics industries. Cobots, or collaborative robots, enhance flexibility by working safely alongside human operators, optimizing tasks like quality inspection, material handling, and small-batch production in sectors like aerospace and pharmaceuticals. The integration of both systems streamlines workflows, increases productivity, and supports customization demands in Industry 4.0 environments.

Workforce Impacts and Human-Robot Collaboration

Industrial robotics enhance manufacturing efficiency by performing repetitive, high-precision tasks with minimal human intervention, leading to reduced labor costs but potential displacement of low-skilled workers. Cobots, designed for safe human-robot collaboration, augment workforce capabilities by handling hazardous or ergonomically challenging tasks while allowing humans to focus on complex decision-making and quality control. This synergy between cobots and workers fosters upskilling, improved job satisfaction, and increased productivity in modern manufacturing environments.

Scalability and Integration Challenges

Industrial robotics offer high scalability through robust automation capabilities suited for large-scale manufacturing processes, but they often require significant upfront investment and complex integration with existing systems. Cobots, designed for close human collaboration, provide flexible scalability with easier deployment and lower integration barriers, adapting quickly to varied production tasks. Both solutions must address challenges such as compatibility with legacy equipment, system interoperability, and workforce training to maximize operational efficiency and scalability.

Future Trends in Industrial Robotics and Cobots

Emerging trends in industrial robotics emphasize enhanced AI integration, enabling robots to perform complex tasks with improved precision and flexibility. Collaborative robots (cobots) are increasingly designed with advanced safety features and adaptive learning capabilities to seamlessly work alongside human operators in dynamic manufacturing environments. The convergence of IoT connectivity and machine learning is driving real-time data analytics, optimizing both industrial robot efficiency and cobot-human collaboration for smarter, connected factories.

Related Important Terms

Human-Robot Collaboration (HRC)

Industrial robotics operate independently with high precision but limited adaptability, whereas cobots are designed for seamless Human-Robot Collaboration (HRC), enhancing flexibility and safety by working alongside human operators. HRC integration in cobots drives productivity improvements and reduces ergonomic risks in manufacturing environments, fostering a more efficient and responsive production line.

Force-Limited Cobots

Force-limited cobots enhance safety and precision in manufacturing by automatically reducing force upon encountering resistance, enabling close human-robot collaboration without risk of injury. Unlike traditional industrial robots that require safety barriers, these cobots integrate advanced sensors and control algorithms to perform delicate tasks such as assembly and quality inspection with improved flexibility and efficiency.

Safety-Rated Monitored Stop

Safety-Rated Monitored Stop enables industrial robots to halt operations immediately when a human enters the workspace, ensuring high levels of safety without compromising productivity. Unlike cobots, which rely on force-limited design for safe human interaction, industrial robots implement this safety function through advanced sensors and control systems certified to international safety standards such as ISO 13849-1 and ISO 10218-1.

Fenceless Automation

Fenceless automation in industrial robotics enhances productivity by enabling high-speed, precise operations within protected perimeters, whereas cobots integrate advanced sensors and AI for safe human-robot collaboration in shared workspaces without physical barriers. This shift reduces factory floor constraints, optimizing space utilization and workflow efficiency while maintaining stringent safety standards.

Adaptive Gripping

Industrial robotics typically utilizes rigid, pre-programmed grippers designed for high-speed, repetitive tasks, whereas cobots feature adaptive gripping technology that allows for flexible handling of diverse objects and shapes. Adaptive gripping in cobots enhances precision and safety by using sensors and machine learning algorithms to adjust grip strength and positioning in real-time.

Artificial Intelligence in Robotics (AI Robotics)

Industrial robotics primarily relies on pre-programmed, repetitive tasks optimized for high-volume manufacturing, while cobots integrate advanced Artificial Intelligence (AI) to adapt dynamically and collaborate safely with human workers in complex environments. AI robotics enhances both systems by enabling real-time decision making, predictive maintenance, and precision control, driving efficiency and flexibility in modern manufacturing processes.

Plug-and-Play Integration

Industrial robotics feature complex programming and extensive setup times, demanding specialized expertise for deployment in manufacturing environments. Cobots offer plug-and-play integration with user-friendly interfaces and minimal configuration, enabling rapid deployment and seamless collaboration with human operators on production lines.

Digital Twin for Robotics

Industrial robotics leverage advanced digital twin technology to simulate, monitor, and optimize complex manufacturing processes, enhancing precision and reducing downtime. Cobots utilize digital twins to enable real-time interaction and adaptive learning, improving collaboration between humans and machines on the factory floor.

Robot-as-a-Service (RaaS)

Robot-as-a-Service (RaaS) transforms industrial robotics by offering scalable, subscription-based access to both industrial robots and collaborative robots (cobots), reducing upfront costs and increasing flexibility for manufacturers. This service model enables seamless integration of autonomous robots into production lines, enhancing operational efficiency and allowing businesses to rapidly adapt to changing demands without heavy capital investment.

Seamless Reprogramming

Industrial robotics offer high-speed, precise automation but often require complex, time-intensive reprogramming for new tasks, limiting agility in dynamic manufacturing environments. Cobots feature seamless reprogramming through intuitive interfaces and adaptive algorithms, enabling rapid task adjustments and enhancing production flexibility.

Industrial Robotics vs Cobots Infographic

industrydif.com

industrydif.com