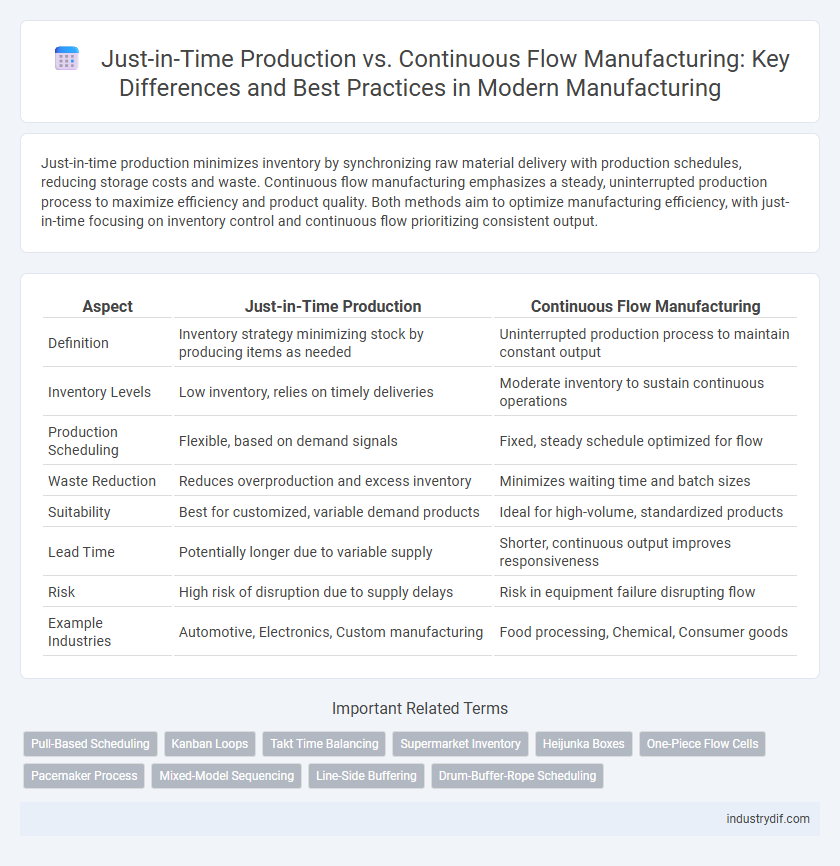

Just-in-time production minimizes inventory by synchronizing raw material delivery with production schedules, reducing storage costs and waste. Continuous flow manufacturing emphasizes a steady, uninterrupted production process to maximize efficiency and product quality. Both methods aim to optimize manufacturing efficiency, with just-in-time focusing on inventory control and continuous flow prioritizing consistent output.

Table of Comparison

| Aspect | Just-in-Time Production | Continuous Flow Manufacturing |

|---|---|---|

| Definition | Inventory strategy minimizing stock by producing items as needed | Uninterrupted production process to maintain constant output |

| Inventory Levels | Low inventory, relies on timely deliveries | Moderate inventory to sustain continuous operations |

| Production Scheduling | Flexible, based on demand signals | Fixed, steady schedule optimized for flow |

| Waste Reduction | Reduces overproduction and excess inventory | Minimizes waiting time and batch sizes |

| Suitability | Best for customized, variable demand products | Ideal for high-volume, standardized products |

| Lead Time | Potentially longer due to variable supply | Shorter, continuous output improves responsiveness |

| Risk | High risk of disruption due to supply delays | Risk in equipment failure disrupting flow |

| Example Industries | Automotive, Electronics, Custom manufacturing | Food processing, Chemical, Consumer goods |

Introduction to Just-in-Time Production

Just-in-Time (JIT) Production minimizes inventory by synchronizing raw material orders with production schedules, reducing waste and storage costs. This system enhances efficiency by producing only what is needed, when it is needed, aligning with lean manufacturing principles. JIT requires robust supplier relationships and precise demand forecasting to prevent bottlenecks and ensure smooth production flow.

Overview of Continuous Flow Manufacturing

Continuous Flow Manufacturing (CFM) integrates production processes into a seamless, uninterrupted sequence that minimizes work-in-progress inventory and reduces lead times. By maintaining a steady flow of materials and consistently balanced workloads, CFM enhances efficiency, quality, and responsiveness to customer demand. This approach is especially effective in high-volume, standardized manufacturing environments where process variability is low and cycle times are tightly controlled.

Key Principles of Just-in-Time Production

Just-in-time (JIT) production is centered on reducing waste by producing only what is needed, when it is needed, and in the exact quantity required. Key principles include inventory minimization, continuous supplier collaboration, and synchronized workflow to eliminate delays. This approach enhances efficiency and responsiveness, directly impacting manufacturing lead times and operational costs.

Core Concepts of Continuous Flow Manufacturing

Continuous Flow Manufacturing (CFM) centers on producing goods in a seamless, uninterrupted flow, minimizing work-in-progress inventory to reduce waste and lead times. By synchronizing processes and balancing workloads across production stages, CFM enhances efficiency and responsiveness to demand changes. This method contrasts with Just-in-Time (JIT) production by emphasizing constant movement through the manufacturing line rather than batch processing or pull systems.

Inventory Management in Both Systems

Just-in-time (JIT) production minimizes inventory levels by synchronizing material deliveries with production schedules, reducing carrying costs and waste. Continuous flow manufacturing maintains a steady inventory buffer to ensure uninterrupted production, optimizing throughput and minimizing downtime. Effective inventory management in JIT demands precise demand forecasting, while continuous flow relies on maintaining balanced inventory levels to prevent bottlenecks.

Waste Reduction Strategies Compared

Just-in-time (JIT) production minimizes waste by synchronizing material deliveries precisely with production schedules, reducing inventory levels and minimizing overproduction. Continuous flow manufacturing emphasizes a steady, uninterrupted workflow that limits work-in-progress inventory and identifies bottlenecks to reduce defects and delays. Both strategies target lean manufacturing goals, but JIT excels in inventory waste reduction while continuous flow optimizes process efficiency and cycle time.

Lead Time and Production Efficiency

Just-in-time (JIT) production minimizes lead time by producing items only as needed, reducing inventory and waste, which enhances production efficiency through streamlined workflows. Continuous Flow Manufacturing (CFM) maintains a steady, uninterrupted production process aimed at maximizing throughput and minimizing delays, resulting in consistently high efficiency and reduced lead time variability. Both strategies improve efficiency, but JIT excels in responsiveness to demand changes while CFM is optimal for stable, high-volume production environments.

Flexibility and Scalability in Operations

Just-in-time (JIT) production enhances operational flexibility by minimizing inventory levels and enabling rapid response to demand fluctuations, while continuous flow manufacturing prioritizes consistent, scalable output through streamlined, uninterrupted processes. JIT's adaptability suits customized orders but can face challenges during demand spikes, whereas continuous flow excels in high-volume, standardized production with scalable capacity. Balancing JIT and continuous flow strategies allows manufacturers to optimize both flexibility and scalability in dynamic market conditions.

Challenges and Risks of Each Approach

Just-in-time production faces challenges such as supply chain disruptions and inventory shortages, which can halt manufacturing processes and increase costs. Continuous flow manufacturing encounters risks related to equipment malfunctions and process inflexibility, leading to prolonged downtime and reduced ability to respond to demand fluctuations. Both approaches demand rigorous coordination and maintenance to minimize operational inefficiencies and ensure consistent product quality.

Choosing the Right Method for Your Manufacturing Process

Selecting between Just-in-time (JIT) Production and Continuous Flow Manufacturing depends on factors such as product complexity, demand variability, and production volume. JIT reduces inventory costs by producing goods only as needed, ideal for customized or low-volume products, while Continuous Flow Manufacturing ensures a constant production rate suited for high-volume, standardized products. Evaluating lead times, supplier reliability, and process flexibility helps optimize efficiency and minimize waste in the manufacturing process.

Related Important Terms

Pull-Based Scheduling

Pull-based scheduling in just-in-time production minimizes inventory levels by producing goods only in response to actual demand, enhancing responsiveness and reducing waste. Continuous flow manufacturing emphasizes steady, uninterrupted movement of materials, optimizing efficiency but relying more on forecasted demand than real-time signals.

Kanban Loops

Kanban loops streamline just-in-time production by signaling inventory replenishment only when needed, reducing waste and improving responsiveness. Continuous flow manufacturing leverages these loops to maintain a steady production rhythm, minimizing delays and optimizing resource utilization for consistent output.

Takt Time Balancing

Takt time balancing is critical in both Just-in-time (JIT) production and Continuous Flow Manufacturing to synchronize production pace with customer demand, minimizing inventory and reducing waste. In JIT, takt time drives the pull system ensuring each process step completes within the takt, while Continuous Flow Manufacturing emphasizes smooth, uninterrupted workflows aligned with takt time to optimize efficiency and resource utilization.

Supermarket Inventory

Supermarket inventory in Just-in-Time (JIT) production acts as a strategic buffer, enabling precise demand-driven replenishment and minimizing excess stock, whereas Continuous Flow Manufacturing relies on steady, uninterrupted material movement without intermediate storage, emphasizing constant throughput. Optimizing supermarket inventory in JIT reduces lead times and waste, enhancing operational efficiency compared to the fixed, high-volume output focus of Continuous Flow Manufacturing.

Heijunka Boxes

Heijunka Boxes play a crucial role in just-in-time (JIT) production by leveling production schedules and minimizing inventory waste through visual workload balancing, contrasting with continuous flow manufacturing that emphasizes a steady, uninterrupted production line. Utilizing Heijunka Boxes enables manufacturers to optimize resource allocation and enhance responsiveness to demand fluctuations, supporting JIT's goal of reducing lead times and improving efficiency.

One-Piece Flow Cells

One-piece flow cells in manufacturing streamline just-in-time production by minimizing inventory and reducing lead times, enabling faster response to customer demand while maintaining high product quality. This approach contrasts with continuous flow manufacturing by emphasizing small batch sizes and flexibility, ultimately enhancing efficiency and decreasing waste through precise, sequential processing.

Pacemaker Process

Just-in-time production relies on the pacemaker process to regulate workflow by triggering production only when needed, minimizing inventory and reducing lead times, whereas continuous flow manufacturing emphasizes a steady, uninterrupted movement of materials through the production line to maximize efficiency and output. The pacemaker process in just-in-time acts as a control point that aligns production rates with customer demand, ensuring synchronization across the supply chain.

Mixed-Model Sequencing

Mixed-model sequencing in just-in-time (JIT) production optimizes inventory levels and reduces lead times by producing varied products in precise sequences based on demand patterns, enhancing flexibility and minimizing waste. Continuous flow manufacturing emphasizes streamlined, uninterrupted processing for high-volume, standardized products, but integrating mixed-model sequencing within this approach requires careful synchronization to maintain flow efficiency while accommodating product variability.

Line-Side Buffering

Line-side buffering in Just-in-Time (JIT) production minimizes inventory by delivering materials exactly when needed, reducing waste and storage costs. Continuous Flow Manufacturing relies less on line-side buffers by maintaining a steady, uninterrupted production rhythm, enhancing process efficiency and throughput.

Drum-Buffer-Rope Scheduling

Drum-Buffer-Rope scheduling in manufacturing synchronizes production flow by setting the drum as the system's constraint, the buffer to protect the drum from disruptions, and the rope to control release of materials, optimizing Just-in-time production efficiency and minimizing inventory. Compared to Continuous Flow Manufacturing, which emphasizes smooth, uninterrupted operations, Drum-Buffer-Rope dynamically manages workflow variability and constraints, enhancing responsiveness and throughput in complex production environments.

Just-in-time Production vs Continuous Flow Manufacturing Infographic

industrydif.com

industrydif.com