The plant floor operates as the traditional hub of manufacturing activities, emphasizing manual labor and localized control systems. In contrast, the connected factory leverages IoT technologies and real-time data analytics to enhance automation, improve efficiency, and enable predictive maintenance. Integrating smart sensors and networked machines, the connected factory transforms production processes into dynamic, adaptive workflows driving higher productivity and reduced downtime.

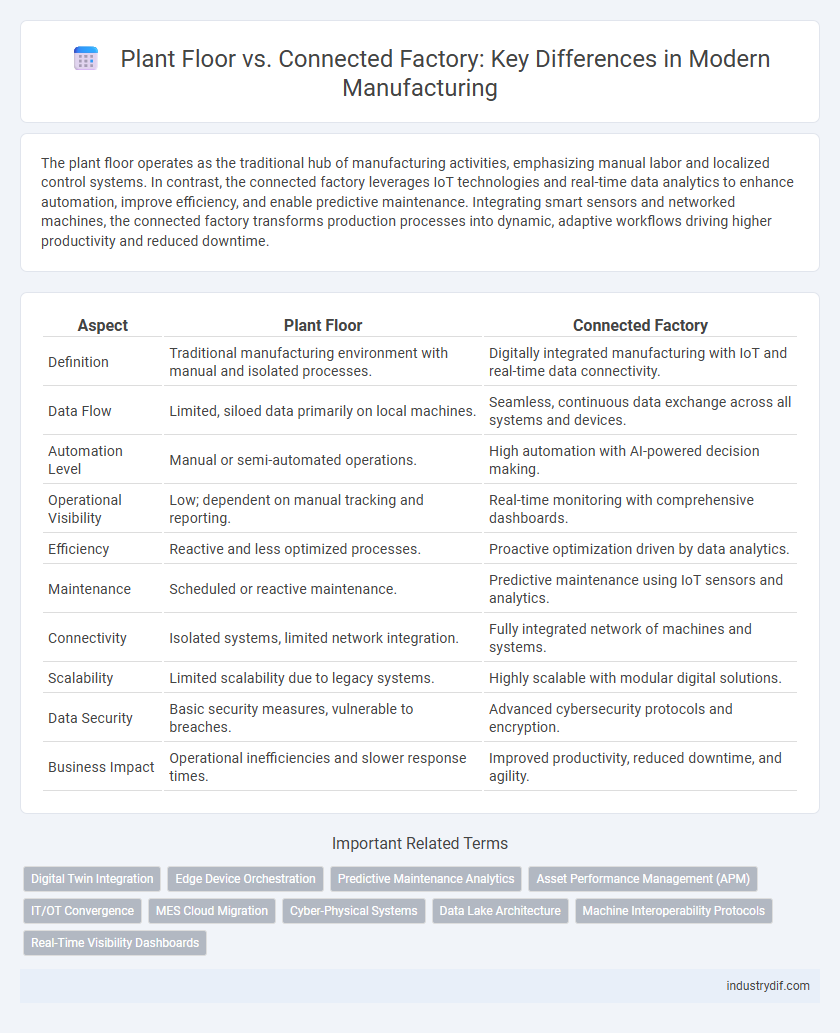

Table of Comparison

| Aspect | Plant Floor | Connected Factory |

|---|---|---|

| Definition | Traditional manufacturing environment with manual and isolated processes. | Digitally integrated manufacturing with IoT and real-time data connectivity. |

| Data Flow | Limited, siloed data primarily on local machines. | Seamless, continuous data exchange across all systems and devices. |

| Automation Level | Manual or semi-automated operations. | High automation with AI-powered decision making. |

| Operational Visibility | Low; dependent on manual tracking and reporting. | Real-time monitoring with comprehensive dashboards. |

| Efficiency | Reactive and less optimized processes. | Proactive optimization driven by data analytics. |

| Maintenance | Scheduled or reactive maintenance. | Predictive maintenance using IoT sensors and analytics. |

| Connectivity | Isolated systems, limited network integration. | Fully integrated network of machines and systems. |

| Scalability | Limited scalability due to legacy systems. | Highly scalable with modular digital solutions. |

| Data Security | Basic security measures, vulnerable to breaches. | Advanced cybersecurity protocols and encryption. |

| Business Impact | Operational inefficiencies and slower response times. | Improved productivity, reduced downtime, and agility. |

Defining the Traditional Plant Floor

The traditional plant floor in manufacturing consists of standalone machines and manual processes that operate independently with limited data integration. It relies heavily on human intervention for monitoring, control, and decision-making, often resulting in slower response times and inefficiencies. This setup contrasts sharply with a connected factory, where real-time data exchange and automation drive enhanced productivity and streamlined operations.

What is a Connected Factory?

A Connected Factory integrates advanced digital technologies such as IoT sensors, real-time data analytics, and automated control systems to optimize manufacturing processes on the plant floor. This smart integration enables seamless communication between machines, production lines, and enterprise systems, enhancing operational efficiency, predictive maintenance, and quality control. Unlike traditional plant floors, Connected Factories leverage connectivity and data-driven insights to drive agile decision-making and enable Industry 4.0 capabilities.

Key Technologies Driving Connected Factories

Key technologies driving connected factories include industrial Internet of Things (IIoT) sensors, advanced robotics, and real-time data analytics platforms that enable seamless communication and operational efficiency across the plant floor. Edge computing enhances data processing speed by analyzing information locally, reducing latency and downtime. Integration of Artificial Intelligence (AI) and machine learning optimizes predictive maintenance, quality control, and production workflows, transforming traditional manufacturing into smart, adaptive systems.

Real-Time Data Collection and Analysis

Plant floor operations rely heavily on manual data collection methods, leading to delays and potential inaccuracies in production monitoring. In contrast, a connected factory implements advanced IoT sensors and automated systems for real-time data collection and analysis, enabling immediate insights into machine performance, quality control, and workflow optimization. Real-time analytics empower manufacturers to reduce downtime, enhance productivity, and make data-driven decisions that improve overall operational efficiency.

Integration of IoT on the Plant Floor

Integration of IoT on the plant floor transforms traditional manufacturing environments by enabling real-time data collection from machinery, improving predictive maintenance and operational efficiency. Connected factories leverage interconnected sensors, automated systems, and cloud computing to optimize production workflows and reduce downtime. This seamless IoT integration enhances visibility across the entire manufacturing process, ensuring smarter decision-making and enhanced resource utilization.

Operational Efficiency: Manual vs Automated

Manual operations on the plant floor often lead to inconsistent production speeds and increased error rates, hindering overall operational efficiency. Automated systems in connected factories utilize real-time data and integrated machinery to streamline workflows, reduce downtime, and enhance accuracy. Implementation of IoT sensors and AI-driven analytics in connected factories maximizes throughput while minimizing waste, surpassing traditional manual methods.

Workforce Skills: Adapting to Smart Manufacturing

Workforce skills in the plant floor environment center on traditional machinery operation and manual process control, emphasizing hands-on expertise and mechanical troubleshooting. In contrast, a connected factory demands advanced digital literacy, proficiency in IoT systems, data analytics, and cyber-physical system management to optimize smart manufacturing processes. Continuous training in AI integration, robotics, and real-time data interpretation becomes essential for employees to maintain productivity and innovation in the connected factory landscape.

Quality Control and Predictive Maintenance

Plant floor operations traditionally focus on manual quality control inspections and reactive maintenance protocols, often leading to delayed defect detection and unexpected equipment downtime. Connected factories utilize IoT sensors and real-time data analytics to enable predictive maintenance, reducing machine failures and improving product quality consistency through continuous monitoring. Integration of advanced automation and AI-driven quality control systems enhances operational efficiency and minimizes production losses compared to conventional plant floor methods.

Scalability and Flexibility in Manufacturing

Plant floor operations often rely on fixed machinery and manual processes, limiting scalability and flexibility in production. In contrast, connected factories utilize IoT integration, real-time data analytics, and automation to enable rapid scaling and adaptive workflows. This digital transformation supports dynamic production scheduling and resource allocation, enhancing responsiveness to market demands.

Challenges and Future Trends in Connected Factories

Connected factories face challenges such as integrating legacy systems with IoT devices, ensuring cybersecurity across interconnected assets, and managing vast data volumes for real-time decision-making. Future trends emphasize advanced AI-driven analytics, edge computing for faster data processing, and the adoption of digital twins to optimize operations and predictive maintenance. Overcoming these obstacles will enable a seamless transition from traditional plant floors to fully connected smart manufacturing environments.

Related Important Terms

Digital Twin Integration

Digital twin integration in manufacturing bridges the gap between plant floor operations and connected factory ecosystems by providing real-time data synchronization and predictive analytics to optimize production efficiency. This technology enables continuous monitoring, simulation, and adjustment of machinery performance, reducing downtime and facilitating adaptive process control across both physical and digital environments.

Edge Device Orchestration

Edge device orchestration enhances plant floor operations by enabling real-time data processing and seamless integration of machines, sensors, and control systems, which optimizes productivity and reduces downtime. In a connected factory, advanced edge orchestration coordinates distributed devices across multiple locations, ensuring scalable automation, improved asset utilization, and streamlined maintenance workflows.

Predictive Maintenance Analytics

Predictive maintenance analytics in a connected factory leverages IoT sensors and real-time data integration across the plant floor to anticipate equipment failures and optimize maintenance schedules. This advanced approach reduces unplanned downtime and extends asset lifespan compared to traditional plant floor methods relying on reactive or scheduled maintenance.

Asset Performance Management (APM)

Plant floor operations rely heavily on manual monitoring and isolated data systems, limiting real-time insight into asset performance and increasing downtime risks. Connected factories leverage Asset Performance Management (APM) platforms that integrate IoT sensors and advanced analytics, enabling predictive maintenance and optimized equipment efficiency across the production line.

IT/OT Convergence

Plant floor environments traditionally operated with isolated OT systems focused on machinery control and real-time data, while connected factories integrate these OT systems with IT infrastructure to enable seamless data exchange and advanced analytics. IT/OT convergence drives enhanced operational efficiency, predictive maintenance, and agile decision-making by unifying information technology and operational technology within manufacturing processes.

MES Cloud Migration

Migrating Manufacturing Execution Systems (MES) to cloud platforms transforms traditional plant floor operations into connected factories by enabling real-time data integration, enhanced scalability, and improved production visibility. Cloud-based MES solutions support predictive maintenance, automated workflows, and seamless IoT connectivity, driving operational efficiency and reducing downtime across manufacturing processes.

Cyber-Physical Systems

Cyber-Physical Systems (CPS) integrate physical plant floor operations with digital connectivity to enable real-time data exchange, process automation, and enhanced monitoring in connected factories. This fusion transforms traditional plant floors into intelligent manufacturing environments, improving efficiency, predictive maintenance, and supply chain responsiveness.

Data Lake Architecture

Plant floor data systems typically operate in isolated silos with limited integration, creating challenges for real-time analytics and predictive maintenance, whereas connected factories leverage a unified Data Lake architecture to aggregate diverse data sources, enabling advanced machine learning and comprehensive operational insights. This integration of IoT sensors, PLCs, and MES data within a centralized Data Lake enhances scalability, data governance, and secure access, driving smarter manufacturing processes and optimized asset performance.

Machine Interoperability Protocols

Plant floor operations rely heavily on legacy machine interoperability protocols such as Modbus and Profibus, which limit real-time data exchange and integration capabilities. Connected factories leverage standardized, IP-based protocols like OPC UA and MQTT to enable seamless communication across diverse machines and systems, enhancing automation and predictive maintenance.

Real-Time Visibility Dashboards

Real-time visibility dashboards in connected factories provide instant access to machine performance, production metrics, and downtime analytics, enabling faster decision-making compared to traditional plant floor systems. These dashboards integrate data from IoT sensors and ERP systems, ensuring comprehensive monitoring and improved operational efficiency across manufacturing processes.

Plant Floor vs Connected Factory Infographic

industrydif.com

industrydif.com