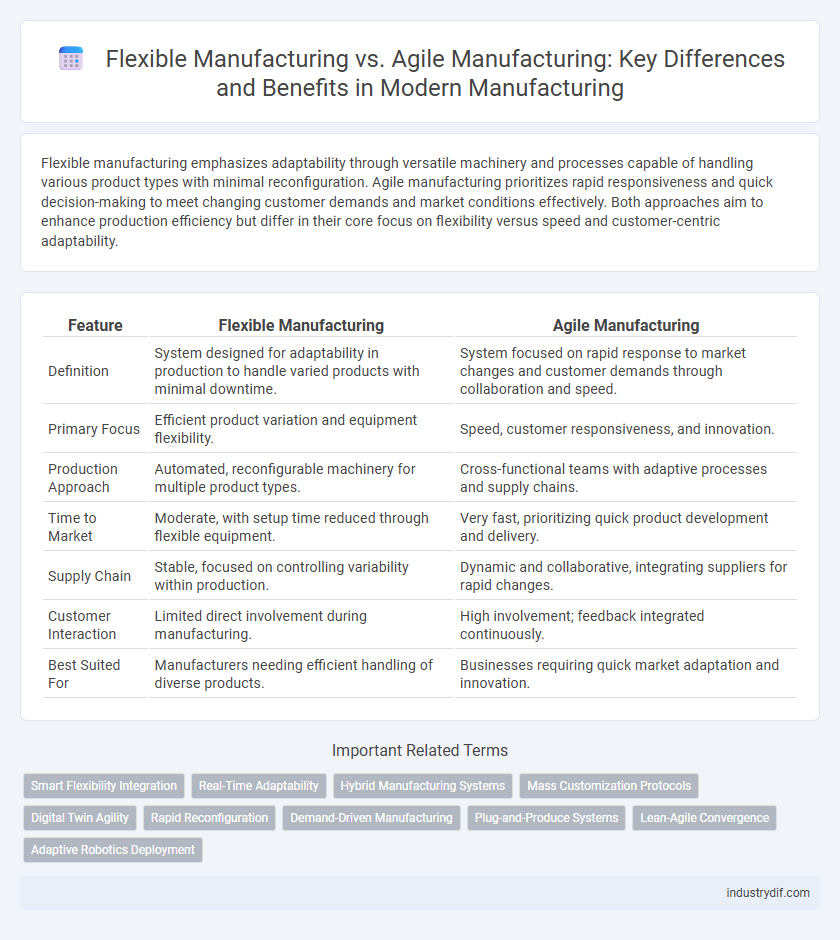

Flexible manufacturing emphasizes adaptability through versatile machinery and processes capable of handling various product types with minimal reconfiguration. Agile manufacturing prioritizes rapid responsiveness and quick decision-making to meet changing customer demands and market conditions effectively. Both approaches aim to enhance production efficiency but differ in their core focus on flexibility versus speed and customer-centric adaptability.

Table of Comparison

| Feature | Flexible Manufacturing | Agile Manufacturing |

|---|---|---|

| Definition | System designed for adaptability in production to handle varied products with minimal downtime. | System focused on rapid response to market changes and customer demands through collaboration and speed. |

| Primary Focus | Efficient product variation and equipment flexibility. | Speed, customer responsiveness, and innovation. |

| Production Approach | Automated, reconfigurable machinery for multiple product types. | Cross-functional teams with adaptive processes and supply chains. |

| Time to Market | Moderate, with setup time reduced through flexible equipment. | Very fast, prioritizing quick product development and delivery. |

| Supply Chain | Stable, focused on controlling variability within production. | Dynamic and collaborative, integrating suppliers for rapid changes. |

| Customer Interaction | Limited direct involvement during manufacturing. | High involvement; feedback integrated continuously. |

| Best Suited For | Manufacturers needing efficient handling of diverse products. | Businesses requiring quick market adaptation and innovation. |

Definition of Flexible Manufacturing

Flexible Manufacturing refers to a production approach designed to easily adapt to changes in product type and volume without significant downtime or cost. It employs advanced machinery and automation systems capable of performing multiple tasks, enabling rapid reconfiguration to meet diverse manufacturing requirements. This system enhances operational efficiency by minimizing setup times and allowing manufacturers to respond swiftly to market demands and customization trends.

Definition of Agile Manufacturing

Agile manufacturing is a production approach centered on rapidly responding to customer needs by leveraging adaptable processes, advanced technologies, and collaborative supply chains. It emphasizes flexibility in product design, efficient resource use, and speed-to-market to accommodate changing market demands. Unlike flexible manufacturing, which focuses on machine adaptability, agile manufacturing integrates organizational agility and real-time data to optimize responsiveness.

Core Principles: Flexibility vs Agility

Flexible manufacturing emphasizes adaptability in production processes by enabling quick adjustments to different product types and volumes through automated machinery and modular systems. Agile manufacturing focuses on responsiveness and speed, integrating real-time data, cross-functional teams, and rapid decision-making to meet dynamic market demands. Both approaches prioritize efficiency, but flexibility centers on structural adaptability, while agility concentrates on operational responsiveness.

Key Technologies in Each Approach

Flexible manufacturing employs CNC machines, robotics, and computer-integrated manufacturing systems to enable rapid reconfiguration of production lines and tooling adjustments. Agile manufacturing leverages advanced sensors, real-time data analytics, IoT connectivity, and AI-driven decision-making tools to respond swiftly to market demand changes and customize products efficiently. Both approaches utilize digital twin technology and additive manufacturing, but agile manufacturing emphasizes cloud computing and machine learning for enhanced adaptability.

Implementation Challenges and Solutions

Flexible manufacturing systems often face implementation challenges such as high initial costs, complex integration with existing processes, and the need for skilled operators to manage automated machinery. Agile manufacturing confronts difficulties including maintaining rapid responsiveness to market changes while ensuring supply chain coordination and workforce adaptability. Solutions involve investing in advanced training programs, leveraging modular technologies, and employing real-time data analytics to enhance operational flexibility and responsiveness.

Production Efficiency: Comparative Analysis

Flexible manufacturing systems enhance production efficiency by enabling quick adaptation to varying product types with minimal downtime, leveraging automated machinery and modular equipment. Agile manufacturing emphasizes rapid response to market changes and customer demands through integrated supply chains and real-time data analytics, boosting overall responsiveness. Comparative analysis shows flexible manufacturing excels in routine volume variability, while agile manufacturing outperforms in speed and customization for dynamic market conditions.

Adaptability to Market Changes

Flexible manufacturing systems use programmable equipment and modular processes to quickly adjust production volumes and product types, enhancing responsiveness to changing market demands. Agile manufacturing emphasizes rapid decision-making, cross-functional collaboration, and real-time data integration to swiftly pivot strategies in response to evolving customer preferences and competitive pressures. The combined adaptability of flexible and agile manufacturing enables firms to maintain efficiency while accelerating innovation cycles in dynamic market environments.

Cost Implications and ROI

Flexible manufacturing systems reduce upfront capital investment by utilizing modular equipment and standardized processes, enabling cost control through efficient resource allocation and minimized downtime. Agile manufacturing, while requiring higher initial expenditure for advanced technologies and workforce training, enhances ROI by rapidly adapting to market fluctuations and customer demands, thus reducing inventory costs and increasing turnover rates. Evaluating cost implications, flexible systems prioritize long-term savings via operational efficiency, whereas agile manufacturing drives ROI through responsiveness and innovation speed.

Case Studies: Industry Applications

Case studies in automotive manufacturing reveal that flexible manufacturing systems (FMS) excel in producing varied product lines with minimal changeover time, optimizing production efficiency in facilities like Toyota's production plants. In contrast, agile manufacturing is highlighted in electronics industries such as Samsung, where rapid response to market demand and customization drives competitive advantage. Both paradigms leverage advanced robotics and real-time data analytics to improve throughput and reduce lead times, but agile manufacturing prioritizes adaptability to fluctuating customer requirements over the scalability emphasized in flexible manufacturing.

Future Trends in Manufacturing Strategies

Flexible manufacturing systems integrate advanced automation and robotics to adapt efficiently to varying product types, enhancing production scalability and cost-effectiveness. Agile manufacturing emphasizes rapid responsiveness to market changes through modular processes and real-time data analytics, enabling customized production at speed. Future trends highlight hybrid models combining flexibility and agility, leveraging AI-driven predictive maintenance and IoT connectivity to optimize supply chains and minimize downtime.

Related Important Terms

Smart Flexibility Integration

Smart flexibility integration in manufacturing combines adaptable automation systems with real-time data analytics to optimize production lines, enabling rapid adjustment to varying product demands and customization levels. This integration enhances both flexible manufacturing's capability for volume variation and agile manufacturing's responsiveness, resulting in a more resilient and efficient production ecosystem.

Real-Time Adaptability

Flexible manufacturing systems enhance real-time adaptability by allowing swift configuration changes to equipment and processes for varied product types. Agile manufacturing emphasizes rapid responsiveness to market fluctuations and customer demands, integrating real-time data analysis for immediate decision-making and operational adjustments.

Hybrid Manufacturing Systems

Hybrid manufacturing systems combine the adaptability of flexible manufacturing with the responsiveness of agile manufacturing, enabling rapid reconfiguration of production lines to meet varying product demands while maintaining efficiency in volume production. These systems leverage advanced automation and real-time data analytics to optimize workflow, reduce downtime, and enhance customization capabilities in dynamic manufacturing environments.

Mass Customization Protocols

Flexible manufacturing systems emphasize adaptability in tooling and equipment to efficiently switch between product variations, supporting mass customization through modular design and scalable processes. Agile manufacturing enhances responsiveness by integrating real-time data and collaborative networks, enabling rapid adjustments to customer-specific requirements within mass customization protocols.

Digital Twin Agility

Digital twin technology enhances flexible manufacturing by creating virtual replicas of production systems that enable real-time adjustments and optimization of workflows. Agile manufacturing leverages digital twin agility to rapidly respond to market changes with data-driven simulations, accelerating prototyping and customization while minimizing downtime.

Rapid Reconfiguration

Flexible manufacturing systems enable rapid reconfiguration by allowing machinery and workflows to be quickly adapted to different product types, reducing downtime and enhancing production efficiency. Agile manufacturing emphasizes rapid responsiveness to market changes through modular processes and cross-functional teams, facilitating swift adjustments in production schedules and customization options.

Demand-Driven Manufacturing

Demand-driven manufacturing prioritizes rapid response to customer demands; flexible manufacturing systems adapt production capabilities to varied products, while agile manufacturing emphasizes swift adjustments in processes and supply chains for real-time demand changes. Both methodologies integrate demand-driven principles to enhance efficiency, reduce lead times, and optimize inventory management in dynamic market environments.

Plug-and-Produce Systems

Plug-and-produce systems enable flexible manufacturing by allowing rapid reconfiguration of production lines to accommodate varying product designs without extensive downtime. Agile manufacturing leverages these systems to respond swiftly to market demands through real-time adaptability and seamless integration of new processes.

Lean-Agile Convergence

Flexible manufacturing emphasizes adaptable equipment and processes to handle varied product types efficiently, while agile manufacturing focuses on rapid responsiveness to market changes and customer demands; lean-agile convergence integrates these approaches by eliminating waste and enhancing flexibility through continuous improvement and fast decision-making. This hybrid strategy drives operational excellence by optimizing resource utilization and accelerating production cycles in dynamic manufacturing environments.

Adaptive Robotics Deployment

Adaptive robotics deployment in flexible manufacturing systems enables rapid reconfiguration of production lines to accommodate varied product types, enhancing operational efficiency and reducing downtime. In contrast, agile manufacturing leverages adaptive robotics to swiftly respond to market changes and customer demands, emphasizing scalability and customization in production processes.

Flexible Manufacturing vs Agile Manufacturing Infographic

industrydif.com

industrydif.com