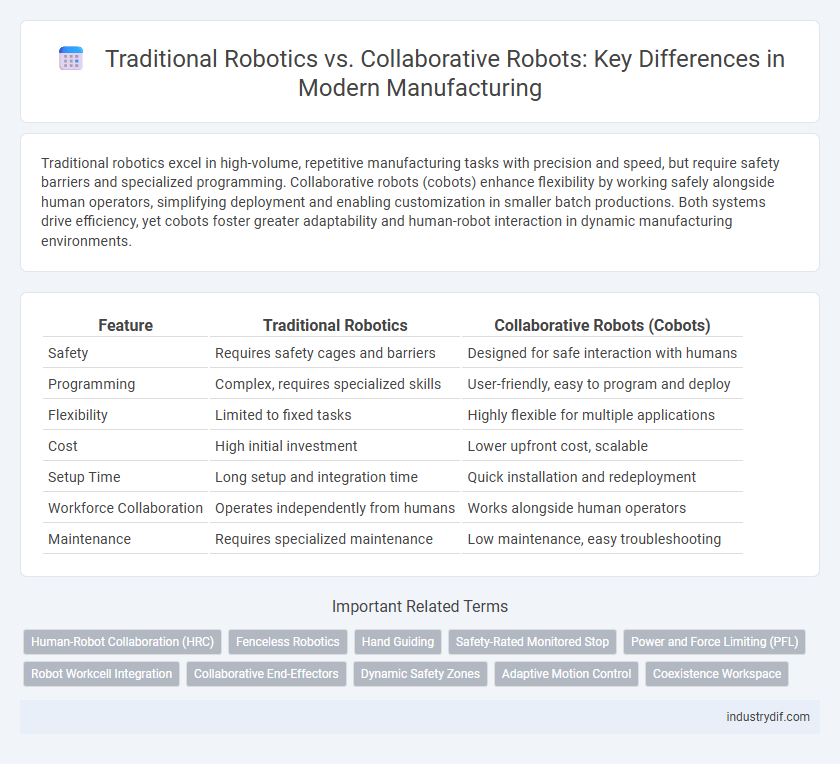

Traditional robotics excel in high-volume, repetitive manufacturing tasks with precision and speed, but require safety barriers and specialized programming. Collaborative robots (cobots) enhance flexibility by working safely alongside human operators, simplifying deployment and enabling customization in smaller batch productions. Both systems drive efficiency, yet cobots foster greater adaptability and human-robot interaction in dynamic manufacturing environments.

Table of Comparison

| Feature | Traditional Robotics | Collaborative Robots (Cobots) |

|---|---|---|

| Safety | Requires safety cages and barriers | Designed for safe interaction with humans |

| Programming | Complex, requires specialized skills | User-friendly, easy to program and deploy |

| Flexibility | Limited to fixed tasks | Highly flexible for multiple applications |

| Cost | High initial investment | Lower upfront cost, scalable |

| Setup Time | Long setup and integration time | Quick installation and redeployment |

| Workforce Collaboration | Operates independently from humans | Works alongside human operators |

| Maintenance | Requires specialized maintenance | Low maintenance, easy troubleshooting |

Overview of Traditional Robotics and Collaborative Robots

Traditional robotics in manufacturing involve pre-programmed, fixed automation systems designed for repetitive, high-volume tasks in controlled environments, offering high precision and speed but limited flexibility. Collaborative robots (cobots) feature advanced sensors and AI, enabling safe human-robot interaction and adaptable performance in dynamic settings, enhancing productivity without extensive safety barriers. The integration of cobots supports agile manufacturing processes by complementing human skills and improving operational efficiency.

Key Differences Between Traditional and Collaborative Robots

Traditional robotics operate in isolated, caged environments with pre-programmed tasks requiring minimal human interaction, emphasizing high precision and repetitive operations in manufacturing. Collaborative robots (cobots) feature advanced sensors and AI, enabling safe human-robot interaction, flexible deployment, and real-time adaptation to changing tasks. Key differences include safety protocols, programming complexity, workspace sharing, and operational flexibility within manufacturing workflows.

Safety Features: Fenced Robots vs Human Collaboration

Traditional robotics typically employ fenced enclosures to ensure safety by physically separating machines from human workers, minimizing risk of accidental contact during high-speed or heavy-load operations. Collaborative robots (cobots) integrate advanced sensors, force limiters, and real-time monitoring systems to enable direct human-robot interaction with built-in safety features that reduce injury risk without the need for protective barriers. The shift from fenced robots to cobots enhances workplace flexibility and efficiency while maintaining stringent safety standards through intelligent design and adaptive response mechanisms.

Flexibility and Adaptability in Manufacturing

Traditional robotics excel in high-volume, repetitive tasks but often lack flexibility, requiring extensive reprogramming and setup for new operations. Collaborative robots (cobots) offer superior adaptability with user-friendly interfaces and easy redeployment, enabling seamless integration into diverse manufacturing environments. This flexibility enhances production agility, reduces downtime, and supports customization in modern manufacturing processes.

Installation and Integration Costs

Traditional robotics systems often require extensive installation and integration efforts, resulting in high upfront costs and longer downtime during deployment. Collaborative robots (cobots) typically feature user-friendly programming and flexible integration capabilities, significantly reducing installation time and associated expenses. Lower integration complexity and faster setup make cobots a cost-effective solution for manufacturers aiming to optimize automation investment.

Productivity and Efficiency Comparisons

Traditional robotics excel in high-volume, repetitive tasks by delivering consistent speed and precision, while collaborative robots (cobots) enhance productivity through flexible deployment and safe human-robot interaction on the factory floor. Cobots reduce downtime and improve efficiency by adapting quickly to varied tasks without extensive programming, making them ideal for small-batch production and customization. Manufacturing facilities integrating cobots report up to a 30% increase in operational efficiency and a 25% reduction in cycle time compared to traditional robotic systems.

Maintenance and Downtime Considerations

Traditional robotics require specialized maintenance teams and often lead to prolonged downtime due to complex troubleshooting and rigid programming. Collaborative robots (cobots) feature modular designs and user-friendly interfaces that simplify maintenance, resulting in reduced downtime and faster recovery from technical issues. The ability to quickly adapt and self-diagnose enables cobots to maintain higher operational efficiency compared to conventional robotic systems.

Human-Robot Interaction in the Workplace

Traditional robotics in manufacturing operate within isolated environments, requiring safety cages to minimize human contact, which limits direct human-robot interaction and flexibility on the shop floor. Collaborative robots (cobots) are designed with advanced sensors and safety features that allow safe, close physical proximity and real-time collaboration with human workers, enhancing productivity and ergonomic support. This shift towards human-robot interaction in workplaces improves task adaptability, reduces injury risks, and enables seamless integration into existing workflows.

Use Case Scenarios: Traditional vs Collaborative Robots

Traditional robotics excel in high-volume, repetitive manufacturing tasks such as automotive assembly lines, where precision and speed are paramount. Collaborative robots (cobots) are ideal for small-batch production, quality inspection, and tasks requiring human-robot interaction, providing flexibility and enhanced safety. Use case scenarios reveal traditional robots optimize productivity in rigid environments, while cobots support dynamic workflows with adaptive task handling.

Future Trends in Manufacturing Robotics

Future trends in manufacturing robotics emphasize the integration of collaborative robots (cobots) alongside traditional industrial robots to enhance flexibility and efficiency on production lines. Advanced machine learning algorithms and AI-powered vision systems enable cobots to safely work alongside human operators, adapting to complex tasks and variable environments. The rise of Industry 4.0 fosters increased connectivity between robotic systems and IoT devices, driving smarter automation and predictive maintenance in manufacturing processes.

Related Important Terms

Human-Robot Collaboration (HRC)

Human-Robot Collaboration (HRC) in manufacturing leverages collaborative robots (cobots) designed to work safely alongside human operators without extensive safety barriers, enhancing flexibility and productivity compared to traditional industrial robots that operate in segregated environments. Cobots' advanced sensors and AI enable real-time interaction and adaptive task sharing, improving precision and reducing human fatigue while maintaining worker safety and operational efficiency.

Fenceless Robotics

Fenceless robotics, a hallmark of collaborative robots (cobots), allows safe human-robot interaction without physical barriers, enhancing flexibility and space efficiency on manufacturing floors. Unlike traditional robotics that require safety fences to isolate high-speed machines, fenceless systems use advanced sensors and AI to detect human presence and prevent collisions, enabling seamless integration in dynamic production environments.

Hand Guiding

Hand guiding in traditional robotics often requires specialized programming and safety barriers, limiting flexibility and human interaction. Collaborative robots integrate intuitive hand guiding capabilities, enabling direct human control and adaptive learning for enhanced precision and safety in manufacturing processes.

Safety-Rated Monitored Stop

Safety-rated monitored stop enables collaborative robots to halt operations instantly when a human enters the workspace, reducing injury risks compared to traditional robotics that often require physical barriers or complete shutdowns. This feature enhances flexible automation by allowing humans and robots to work side-by-side without compromising safety or productivity.

Power and Force Limiting (PFL)

Traditional robotics rely on high power and speed for efficiency, often requiring safety barriers due to limited force limiting capabilities. Collaborative robots feature advanced Power and Force Limiting (PFL) technologies, enabling safe interaction with human workers by automatically reducing power output upon contact to prevent injury.

Robot Workcell Integration

Traditional robotics in manufacturing rely on fixed, caged robot workcells designed for high-speed, repetitive tasks with limited human interaction, ensuring safety and maximizing production efficiency. Collaborative robots (cobots) feature sensor-integrated workcell designs that enable safe human-robot interaction, flexible task adaptation, and seamless integration into existing production lines without extensive safety barriers.

Collaborative End-Effectors

Collaborative end-effectors in manufacturing enhance flexibility and safety by enabling robots to work alongside humans without extensive safety barriers, adapting to diverse tasks through advanced sensors and AI-driven precision. These end-effectors outperform traditional robotics by offering intuitive, real-time responsiveness, improving productivity and reducing downtime in dynamic production environments.

Dynamic Safety Zones

Traditional robotics rely on fixed safety barriers to separate humans and machines, limiting flexibility and workspace efficiency; collaborative robots utilize dynamic safety zones, integrating sensors and real-time monitoring to adjust operational boundaries and enhance human-robot interaction safety. Dynamic safety zones enable collaborative robots to adapt to changing environments, reducing downtime and increasing productivity within manufacturing processes.

Adaptive Motion Control

Traditional robotics rely on pre-programmed, rigid motion paths that limit flexibility in dynamic manufacturing environments, whereas collaborative robots utilize adaptive motion control to seamlessly adjust movements in real-time based on sensor feedback. This capability enhances safety, increases precision, and enables efficient human-robot interaction on assembly lines.

Coexistence Workspace

Traditional robotics systems operate within segregated workspaces designed for high-speed, repetitive tasks, ensuring safety through physical barriers and limited human interaction. Collaborative robots (cobots) enable shared workspaces by incorporating advanced sensors and adaptive controls, allowing seamless coexistence with human workers for enhanced flexibility and productivity in manufacturing environments.

Traditional Robotics vs Collaborative Robots Infographic

industrydif.com

industrydif.com