Six Sigma emphasizes reducing process variation and eliminating defects through data-driven methodologies, driving consistent quality improvements in manufacturing. Quality 4.0 integrates digital technologies like IoT, AI, and big data analytics to enhance real-time quality monitoring and predictive maintenance. Combining Six Sigma with Quality 4.0 empowers manufacturers to optimize processes, increase efficiency, and achieve higher product quality standards.

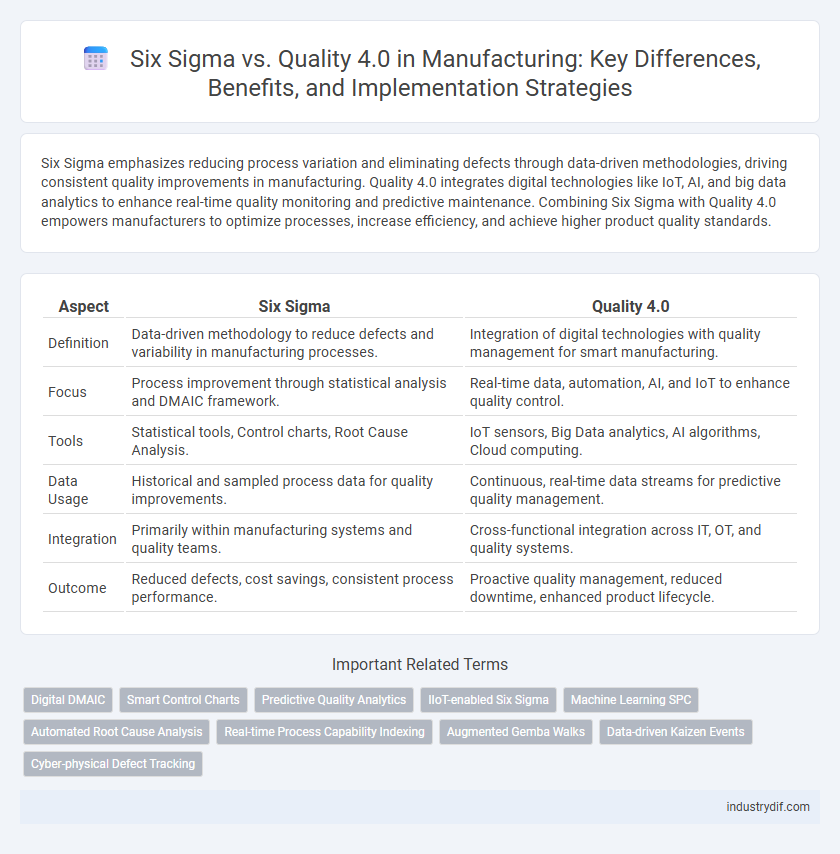

Table of Comparison

| Aspect | Six Sigma | Quality 4.0 |

|---|---|---|

| Definition | Data-driven methodology to reduce defects and variability in manufacturing processes. | Integration of digital technologies with quality management for smart manufacturing. |

| Focus | Process improvement through statistical analysis and DMAIC framework. | Real-time data, automation, AI, and IoT to enhance quality control. |

| Tools | Statistical tools, Control charts, Root Cause Analysis. | IoT sensors, Big Data analytics, AI algorithms, Cloud computing. |

| Data Usage | Historical and sampled process data for quality improvements. | Continuous, real-time data streams for predictive quality management. |

| Integration | Primarily within manufacturing systems and quality teams. | Cross-functional integration across IT, OT, and quality systems. |

| Outcome | Reduced defects, cost savings, consistent process performance. | Proactive quality management, reduced downtime, enhanced product lifecycle. |

Introduction to Six Sigma and Quality 4.0

Six Sigma is a data-driven methodology aimed at reducing defects and improving process quality through statistical analysis and DMAIC principles. Quality 4.0 integrates digital technologies such as IoT, AI, and big data analytics into quality management, enabling real-time monitoring and predictive insights. Combining Six Sigma's structured problem-solving approach with Quality 4.0's advanced digital tools enhances manufacturing efficiency and product reliability.

Core Principles: Six Sigma vs Quality 4.0

Six Sigma focuses on reducing process variation and defects through data-driven methodologies and DMAIC cycles, emphasizing precision and consistency in manufacturing quality. Quality 4.0 integrates digital technologies such as IoT, AI, and Big Data analytics to enable real-time monitoring, predictive maintenance, and adaptive quality control processes. Core principles of Six Sigma target defect elimination and statistical process control, while Quality 4.0 centers on connectivity, data integration, and intelligent automation for continuous improvement.

Historical Evolution in Manufacturing

Six Sigma emerged in the 1980s as a data-driven methodology aimed at reducing defects and improving process consistency through statistical analysis. Quality 4.0 represents an evolution driven by Industry 4.0 technologies, integrating IoT, AI, and big data analytics to enhance real-time quality monitoring and predictive maintenance. This transition reflects manufacturing's shift from traditional, reactive quality control to a proactive, connected, and intelligent quality management system.

Methodologies and Tools Comparison

Six Sigma relies on data-driven statistical methodologies such as DMAIC (Define, Measure, Analyze, Improve, Control) and tools like Control Charts, Pareto Analysis, and Failure Mode and Effects Analysis (FMEA) to reduce variation and defects in manufacturing processes. Quality 4.0 integrates advanced digital technologies including IoT sensors, AI-powered analytics, and real-time data visualization platforms to enable predictive quality management and continuous process optimization. The convergence of traditional Six Sigma techniques with Quality 4.0's smart manufacturing tools enhances precision, accelerates root cause analysis, and fosters adaptive quality control systems.

Data-Driven Decision Making Approaches

Six Sigma uses statistical analysis and process control charts to identify and reduce defects with a focus on improving manufacturing quality through empirical data. Quality 4.0 leverages advanced technologies such as IoT, AI, and big data analytics to enable real-time monitoring and predictive insights for smarter, data-driven decision making. Integrating these approaches enhances precision in quality improvement by combining Six Sigma's rigorous methodology with Quality 4.0's digital data ecosystems.

Role of Digital Transformation

Digital transformation drives Quality 4.0 by integrating advanced technologies like IoT, AI, and big data analytics to enhance manufacturing processes and real-time quality control. Six Sigma focuses on reducing process variability and defects through statistical methods, while Quality 4.0 leverages digital tools to achieve predictive insights and adaptive quality management. This synergy enables manufacturers to optimize efficiency, reduce costs, and accelerate innovation beyond traditional Six Sigma frameworks.

Key Benefits and Value Propositions

Six Sigma delivers data-driven process improvements by reducing variation and defects, resulting in higher product quality and operational efficiency. Quality 4.0 leverages advanced digital technologies like IoT, AI, and big data analytics to enable real-time quality monitoring, predictive maintenance, and enhanced decision-making. Combining Six Sigma with Quality 4.0 drives continuous improvement and innovation, leading to reduced costs, accelerated time-to-market, and superior customer satisfaction in manufacturing.

Implementation Challenges and Best Practices

Implementing Six Sigma often faces challenges such as resistance to change, data quality issues, and the necessity for extensive employee training, while Quality 4.0 integration struggles with the complexity of digital transformation and cybersecurity concerns. Best practices include fostering a culture of continuous improvement and leveraging advanced analytics for real-time decision-making in Quality 4.0, alongside establishing strong leadership commitment and disciplined project management for Six Sigma. Combining Six Sigma's structured methodology with Quality 4.0 technologies like IoT and AI enables manufacturers to overcome implementation barriers and enhance process optimization effectively.

Case Studies: Six Sigma and Quality 4.0 in Action

Case studies reveal that Six Sigma improves manufacturing quality by reducing defects through data-driven process control and statistical analysis, resulting in significant cost savings and enhanced customer satisfaction. Quality 4.0 leverages IoT, AI, and big data analytics to enable real-time monitoring and predictive maintenance, driving continuous improvement and operational efficiency in smart factories. Combining Six Sigma methodologies with Quality 4.0 technologies maximizes quality outcomes by integrating traditional process excellence with advanced digital capabilities.

Future Trends in Manufacturing Quality Management

Six Sigma remains a cornerstone in manufacturing quality management by emphasizing defect reduction through statistical analysis, while Quality 4.0 integrates advanced digital technologies like IoT, AI, and big data to enhance real-time process monitoring and predictive capabilities. Future trends indicate a shift towards hybrid approaches combining Six Sigma's rigorous methodology with Quality 4.0's data-driven insights to achieve smarter, more adaptive quality control systems. Embracing Industry 4.0 technologies will enable manufacturers to improve product quality, reduce downtime, and accelerate continuous improvement cycles in increasingly complex production environments.

Related Important Terms

Digital DMAIC

Digital DMAIC integrates advanced data analytics, IoT sensors, and AI-driven insights into the traditional Six Sigma framework, enhancing defect detection and process optimization in manufacturing. Quality 4.0 leverages this digital DMAIC approach to enable real-time decision-making, predictive maintenance, and continuous improvement, transforming quality management with Industry 4.0 technologies.

Smart Control Charts

Six Sigma emphasizes statistical control through traditional control charts for defect reduction, while Quality 4.0 integrates Smart Control Charts leveraging IoT sensors, real-time data analytics, and AI-driven anomaly detection to enhance manufacturing process monitoring. Smart Control Charts enable proactive quality management by dynamically adjusting control limits based on live production variables, optimizing process capability and reducing waste more efficiently than conventional Six Sigma methods.

Predictive Quality Analytics

Six Sigma emphasizes defect reduction through statistical analysis and process control, while Quality 4.0 leverages Predictive Quality Analytics powered by AI and IoT to anticipate quality issues in real-time. Integrating machine learning models with sensor data enables manufacturers to transition from reactive inspections to proactive quality management, enhancing overall production efficiency and reducing waste.

IIoT-enabled Six Sigma

IIoT-enabled Six Sigma integrates Industrial Internet of Things technology with traditional Six Sigma methodologies, enhancing real-time data collection and analytics for process optimization and defect reduction in manufacturing. This synergy accelerates root cause analysis and continuous improvement cycles, surpassing Quality 4.0's focus on digital transformation alone by embedding precise, data-driven decision-making within Six Sigma frameworks.

Machine Learning SPC

Machine Learning-driven Statistical Process Control (SPC) in Quality 4.0 enables real-time defect detection and predictive analytics, surpassing traditional Six Sigma methods that rely heavily on historical data and manual analysis. Integrating AI algorithms with IoT sensors enhances process optimization by identifying complex patterns and reducing variability more efficiently than classic Six Sigma tools.

Automated Root Cause Analysis

Six Sigma emphasizes data-driven statistical methods for automated root cause analysis to reduce process variation and defects, while Quality 4.0 integrates advanced digital technologies such as AI, IoT, and machine learning for real-time, automated root cause detection and corrective action. Manufacturing industries leveraging Quality 4.0 benefit from enhanced predictive analytics and faster decision-making efficiency compared to traditional Six Sigma approaches.

Real-time Process Capability Indexing

Six Sigma employs statistical methods to enhance manufacturing quality by reducing process variation through Phase-specific controls, while Quality 4.0 integrates real-time data analytics and Internet of Things (IoT) technologies for continuous process capability indexing. Real-time Process Capability Indexing under Quality 4.0 enables dynamic monitoring and instant decision-making, significantly improving response time and manufacturing precision compared to traditional Six Sigma approaches.

Augmented Gemba Walks

Six Sigma emphasizes data-driven process improvement and defect reduction, while Quality 4.0 integrates digital technologies like IoT, AI, and augmented reality to enhance real-time insights during augmented Gemba Walks. Augmented Gemba Walks leverage smart sensors and wearable devices to collect precise operational data, enabling proactive quality control and faster decision-making on the manufacturing floor.

Data-driven Kaizen Events

Data-driven Kaizen events under Six Sigma utilize statistical analysis and process control tools to identify and eliminate defects, fostering continuous improvement with precision. Quality 4.0 integrates advanced digital technologies and real-time analytics, enabling predictive insights and faster decision-making to optimize manufacturing processes.

Cyber-physical Defect Tracking

Cyber-physical defect tracking integrates real-time sensor data with Six Sigma methodologies to enhance precision in identifying and reducing manufacturing defects. Quality 4.0 leverages IoT devices, AI analytics, and machine learning to optimize defect detection processes, surpassing traditional Six Sigma by providing adaptive, data-driven insights for continuous improvement.

Six Sigma vs Quality 4.0 Infographic

industrydif.com

industrydif.com