Mass production emphasizes the continuous, large-scale manufacturing of identical products, optimizing efficiency and minimizing unit costs through standardized processes. Batch-of-one production prioritizes customization and flexibility, allowing manufacturers to produce unique, tailor-made items without compromising quality. Selecting between these methods depends on demand variability, production volume, and the balance between cost-efficiency and product personalization.

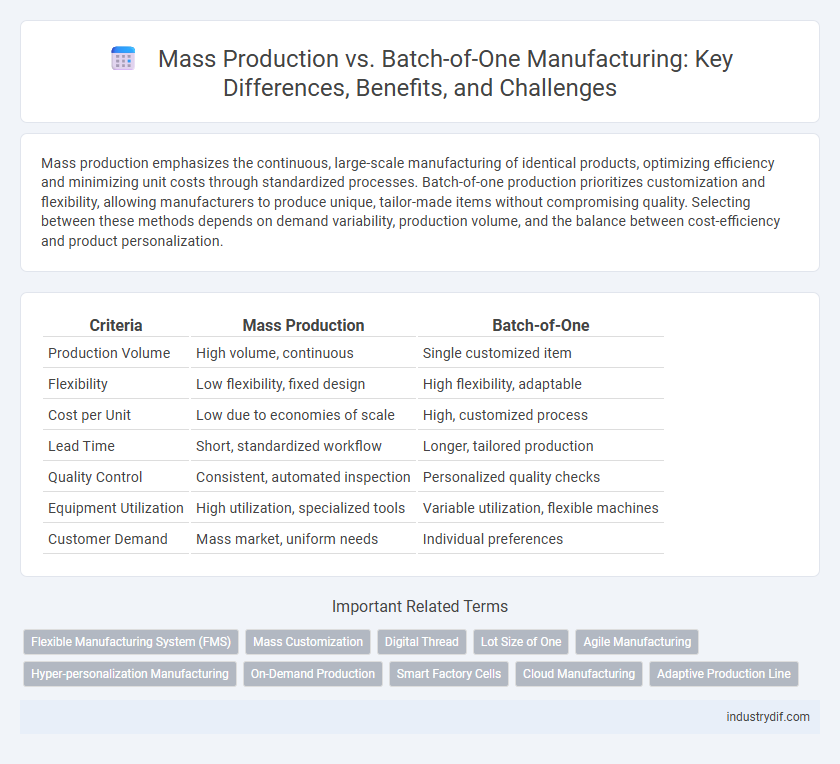

Table of Comparison

| Criteria | Mass Production | Batch-of-One |

|---|---|---|

| Production Volume | High volume, continuous | Single customized item |

| Flexibility | Low flexibility, fixed design | High flexibility, adaptable |

| Cost per Unit | Low due to economies of scale | High, customized process |

| Lead Time | Short, standardized workflow | Longer, tailored production |

| Quality Control | Consistent, automated inspection | Personalized quality checks |

| Equipment Utilization | High utilization, specialized tools | Variable utilization, flexible machines |

| Customer Demand | Mass market, uniform needs | Individual preferences |

Understanding Mass Production and Batch-of-One

Mass production involves the continuous manufacturing of large quantities of standardized products using assembly line techniques and automation to maximize efficiency and reduce per-unit costs. Batch-of-One production focuses on creating highly customized products individually, leveraging flexible machinery and advanced technologies like 3D printing to meet specific customer requirements. Understanding the trade-offs between the scalability and cost-effectiveness of mass production versus the personalization and agility of batch-of-one is critical for optimizing manufacturing strategies.

Key Differences Between Mass Production and Batch-of-One

Mass production focuses on high-volume output using standardized processes to achieve economies of scale, while batch-of-one manufacturing emphasizes customized products tailored to individual customer specifications. Mass production leverages automated assembly lines and uniform materials to minimize costs and maximize efficiency, whereas batch-of-one relies on flexible machinery and skilled labor to produce unique, low-quantity orders. Lead times in mass production are significantly shorter for large volumes, contrasting with the longer, more variable lead times inherent in batch-of-one due to customization requirements.

Advantages of Mass Production in Modern Manufacturing

Mass production significantly reduces per-unit costs through economies of scale, enabling manufacturers to achieve high efficiency and consistent product quality. This method leverages automation and standardized processes, resulting in rapid output and minimized production time. Consistent supply chain management and predictable demand fulfillment further amplify mass production's role in meeting large market volumes effectively.

Benefits of Batch-of-One for Customization

Batch-of-One manufacturing enables unparalleled customization by producing unique products tailored to individual customer specifications, significantly enhancing customer satisfaction and market differentiation. This approach reduces inventory waste and minimizes the risks associated with inaccurate demand forecasting typical in mass production. Leveraging advanced manufacturing technologies like 3D printing and CNC machining, Batch-of-One facilitates rapid design changes and personalized solutions without the high costs of large-scale setups.

Cost Efficiency: Mass Production vs Batch-of-One

Mass production achieves significant cost efficiency through economies of scale, reducing per-unit costs by producing large volumes of identical products with streamlined processes and automated machinery. In contrast, batch-of-one manufacturing incurs higher costs per unit due to customization, frequent changeovers, and less automation, despite offering greater flexibility and personalization. Companies must balance cost efficiency with product variety and customer demand when choosing between mass production and batch-of-one strategies.

Lead Time and Flexibility Comparison

Mass production significantly reduces lead time by streamlining processes to produce large quantities of identical products efficiently, making it ideal for high-demand items. Batch-of-one manufacturing offers unparalleled flexibility, allowing customized products with minimal setup changes but typically results in longer lead times due to individualized production steps. Comparing both, mass production excels in speed and cost-efficiency for uniform products, whereas batch-of-one prioritizes customization and adaptability at the expense of faster delivery.

Quality Control in Mass Production vs Batch-of-One

Mass production relies on standardized processes and automated quality control systems to ensure consistent product quality across high volumes, minimizing defects through statistical process control and real-time monitoring. Conversely, batch-of-one manufacturing focuses on individualized quality inspections and customized adjustments, requiring flexible quality control approaches to address unique specifications for each unit. While mass production optimizes uniformity and efficiency, batch-of-one emphasizes precision and adaptability in quality management.

Impact of Industry 4.0 on Production Models

Industry 4.0 technologies, including IoT, AI, and advanced robotics, are revolutionizing mass production by enabling real-time data analytics and predictive maintenance, thus significantly enhancing efficiency and reducing downtime. The integration of digital twins and cyber-physical systems supports batch-of-one manufacturing by allowing highly customized production without sacrificing speed or quality. Smart factories leverage these Industry 4.0 innovations to create flexible production models that optimize resource use and adapt quickly to changing market demands.

Choosing the Right Approach for Your Manufacturing Needs

Mass production excels in delivering high volumes of standardized products with consistent quality, optimizing cost-efficiency and reducing per-unit expenses. Batch-of-one manufacturing offers unparalleled customization and flexibility, catering to unique customer specifications and enabling rapid adaptation to market changes. Selecting the appropriate manufacturing approach hinges on factors such as order size, product complexity, and customer demand for personalization, ensuring alignment with operational goals and resource capabilities.

Future Trends: Hybrid Production Strategies

Hybrid production strategies combine mass production efficiency with batch-of-one customization to meet evolving market demands. Advanced technologies like AI-driven automation and flexible manufacturing systems enable seamless switching between large-scale output and highly personalized products. This approach maximizes resource utilization while delivering tailored solutions, driving competitiveness in the future manufacturing landscape.

Related Important Terms

Flexible Manufacturing System (FMS)

Flexible Manufacturing Systems (FMS) enable efficient transition between mass production and batch-of-one by utilizing automated machinery and real-time scheduling to optimize customization and volume. This adaptability reduces lead times and production costs while maintaining high quality across variable batch sizes in manufacturing processes.

Mass Customization

Mass customization integrates the efficiency of mass production with the flexibility of batch-of-one manufacturing, enabling companies to deliver personalized products at scale without sacrificing cost-effectiveness. Advanced technologies such as modular design, automation, and digital supply chains drive this approach, allowing manufacturers to meet diverse customer demands while maintaining high throughput and reduced lead times.

Digital Thread

Mass production relies on standardized processes and economies of scale, while batch-of-one manufacturing demands flexibility and customization, both benefiting significantly from the digital thread's real-time data integration to enhance traceability, quality control, and agile decision-making. Implementing a digital thread connects design, production, and supply chain data, enabling seamless transitions between mass production and batch-of-one, which optimizes efficiency and responsiveness in modern manufacturing environments.

Lot Size of One

Mass production emphasizes large-scale output with uniform products, optimizing economies of scale, while batch-of-one manufacturing centers on producing customized items with a lot size of one, offering maximum flexibility and personalization. The lot size of one approach reduces inventory costs and lead times, enabling companies to quickly respond to unique customer demands and market changes.

Agile Manufacturing

Agile manufacturing enables rapid shifts between mass production and batch-of-one processes by leveraging flexible automation and real-time data analytics, optimizing efficiency and customization simultaneously. This approach reduces lead times and inventory costs while enhancing responsiveness to market demand and individual customer specifications.

Hyper-personalization Manufacturing

Hyper-personalization manufacturing leverages batch-of-one production to deliver custom products tailored to individual customer preferences, enhancing customer satisfaction and market differentiation. Unlike traditional mass production, which emphasizes high volume and uniformity, batch-of-one manufacturing integrates flexible automation and data-driven design to efficiently produce unique items at scale.

On-Demand Production

On-demand production emphasizes flexibility by manufacturing goods only when orders are received, reducing inventory costs compared to traditional mass production that relies on high-volume, standardized output. This approach aligns with batch-of-one strategies, enabling customized products at scale while minimizing waste and lead time.

Smart Factory Cells

Smart factory cells enable flexible manufacturing by integrating advanced robotics and IoT, allowing seamless shifts between mass production and batch-of-one customization. This adaptability minimizes downtime and reduces costs while enhancing product quality through real-time data analytics and machine learning algorithms.

Cloud Manufacturing

Cloud manufacturing enables seamless integration of mass production and batch-of-one processes by leveraging real-time data analytics and flexible resource allocation to optimize efficiency and customization. This approach reduces lead times, lowers costs, and enhances scalability by dynamically adapting production workflows in response to market demand and customer specifications.

Adaptive Production Line

Adaptive production lines enable seamless transitions between mass production and batch-of-one manufacturing by utilizing flexible automation and real-time data analytics, optimizing efficiency and customization. This approach reduces downtime and inventory costs while meeting diverse customer demands through scalable and responsive manufacturing processes.

Mass Production vs Batch-of-One Infographic

industrydif.com

industrydif.com