Design for Manufacturability (DFM) emphasizes optimizing product designs to simplify production processes, reduce costs, and enhance quality by considering manufacturing constraints early in the design phase. Generative Design utilizes advanced algorithms and artificial intelligence to automatically generate multiple design alternatives based on specific performance criteria and manufacturing limitations. Integrating DFM principles with generative design tools accelerates innovation while ensuring practicality and efficiency in manufacturing workflows.

Table of Comparison

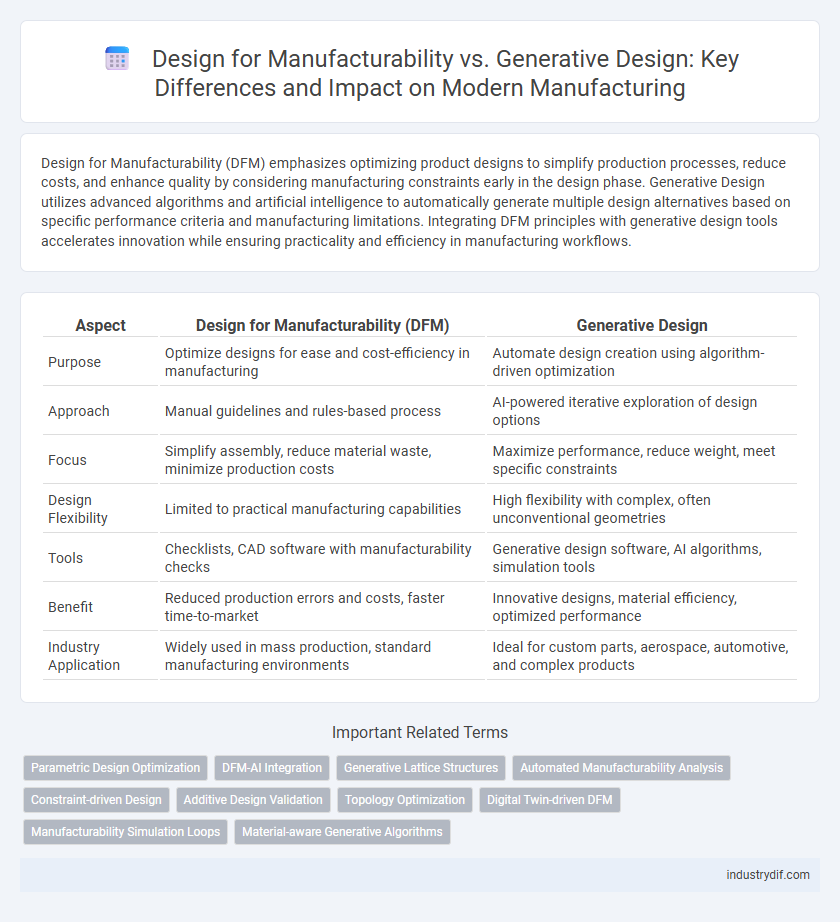

| Aspect | Design for Manufacturability (DFM) | Generative Design |

|---|---|---|

| Purpose | Optimize designs for ease and cost-efficiency in manufacturing | Automate design creation using algorithm-driven optimization |

| Approach | Manual guidelines and rules-based process | AI-powered iterative exploration of design options |

| Focus | Simplify assembly, reduce material waste, minimize production costs | Maximize performance, reduce weight, meet specific constraints |

| Design Flexibility | Limited to practical manufacturing capabilities | High flexibility with complex, often unconventional geometries |

| Tools | Checklists, CAD software with manufacturability checks | Generative design software, AI algorithms, simulation tools |

| Benefit | Reduced production errors and costs, faster time-to-market | Innovative designs, material efficiency, optimized performance |

| Industry Application | Widely used in mass production, standard manufacturing environments | Ideal for custom parts, aerospace, automotive, and complex products |

Introduction to Design for Manufacturability (DFM)

Design for Manufacturability (DFM) is a critical engineering approach that focuses on designing products to simplify manufacturing processes, reduce production costs, and enhance product quality. It emphasizes early-stage collaboration between design and manufacturing teams to optimize material selection, assembly methods, and tolerances. Integrating DFM principles helps streamline production workflows, minimize errors, and ensure products are easy to fabricate and assemble in high-volume manufacturing environments.

What Is Generative Design?

Generative Design is an advanced manufacturing approach that uses algorithms and artificial intelligence to explore numerous design alternatives based on specified constraints like material, performance, and manufacturing methods. Unlike traditional Design for Manufacturability (DFM) which optimizes designs for ease of production, Generative Design actively generates innovative, optimized structures that reduce weight and improve strength while often enabling cost-effective manufacturing processes. This technology accelerates product development by integrating engineering requirements with automated design exploration, resulting in highly efficient, optimized components.

Key Principles of DFM in Manufacturing

Design for Manufacturability (DFM) emphasizes optimizing product designs to simplify manufacturing processes, reduce costs, and improve quality by integrating considerations such as material selection, tolerance standardization, and process capabilities early in development. Key principles of DFM include minimizing part count, enhancing assembly efficiency, and ensuring ease of fabrication and inspection to streamline production cycles. Generative Design complements DFM by using AI-driven algorithms to create optimized design alternatives, but DFM remains critical for grounding designs in practical manufacturability constraints.

Core Algorithms Behind Generative Design

Core algorithms behind generative design leverage advanced techniques such as topology optimization, evolutionary algorithms, and machine learning to explore vast design spaces efficiently. These algorithms generate multiple optimized design alternatives that meet specified constraints including material usage, strength, and manufacturing feasibility. Unlike traditional Design for Manufacturability, which emphasizes pre-defined guidelines, generative design algorithms enable innovative solutions by simulating real-world performance and iteratively refining designs for optimal manufacturability and functionality.

Material Selection: DFM vs Generative Approaches

Design for Manufacturability (DFM) emphasizes selecting materials that streamline production processes, reduce costs, and ensure compatibility with existing manufacturing technologies. In contrast, generative design leverages algorithm-driven optimization to explore innovative material combinations, prioritizing performance and weight reduction over traditional manufacturability constraints. The choice between DFM and generative design significantly impacts material selection strategies, balancing practicality with cutting-edge design possibilities.

Prototyping and Validation: Traditional vs AI-driven Methods

Design for Manufacturability (DfM) emphasizes creating prototypes that minimize production costs and simplify assembly using traditional CAD models and physical testing, ensuring manufacturability early in the design phase. Generative Design leverages AI algorithms to rapidly generate and validate multiple prototype iterations digitally, optimizing for structural integrity and material usage before physical prototyping. AI-driven methods accelerate validation through simulation and predictive analytics, reducing prototype cycles and enhancing product performance refinement compared to conventional trial-and-error approaches.

Cost Efficiency: Comparative Analysis

Design for Manufacturability (DFM) emphasizes reducing production costs by simplifying product features, optimizing material use, and minimizing manufacturing complexity. Generative Design leverages AI algorithms to create multiple design alternatives, focusing on material efficiency and weight reduction, which can lead to significant cost savings in raw materials and assembly. Comparative analysis shows DFM offers predictable cost control during mass production, while Generative Design excels in innovative cost reduction through optimized geometry and automation in prototyping.

Impact on Production Lead Time

Design for Manufacturability (DfM) prioritizes simplifying product features to reduce complexity, directly shortening production lead times by minimizing rework and assembly issues. Generative Design employs AI algorithms to optimize parts based on specific criteria, potentially reducing lead times through innovative material usage and process efficiency but may require extended initial design validation. Combining DfM principles with generative design can create faster, more efficient production cycles by balancing manufacturability constraints with optimized design variations.

Industry Use Cases: DFM and Generative Design

Design for Manufacturability (DFM) streamlines production by optimizing product designs to minimize manufacturing complexities and costs, widely applied in automotive and aerospace industries. Generative Design leverages AI algorithms to create multiple design alternatives based on performance criteria, enhancing innovation in consumer electronics and medical device manufacturing. Combining DFM and generative design accelerates prototype development and improves product quality across advanced manufacturing sectors.

Future Trends in Manufacturing Design Technologies

Future trends in manufacturing design technologies highlight an increasing integration of Design for Manufacturability (DFM) principles with Generative Design algorithms, enabling optimized production efficiency and material utilization. Advances in AI-driven generative design tools allow rapid exploration of complex geometries while ensuring manufacturability constraints are met, reducing prototype iterations and production costs. Emerging technologies such as additive manufacturing and digital twins further enhance this synergy, fostering innovation in lightweight structures and sustainable manufacturing processes.

Related Important Terms

Parametric Design Optimization

Design for Manufacturability (DFM) emphasizes simplifying product features to reduce production costs and improve assembly efficiency, while Generative Design leverages algorithms to explore complex geometries for performance-driven innovation. Parametric Design Optimization integrates both approaches by adjusting design variables within predefined constraints to achieve optimal manufacturability and functional performance, enhancing material usage and reducing production time.

DFM-AI Integration

Design for Manufacturability (DFM) emphasizes optimizing product designs to simplify manufacturing processes and reduce production costs, while Generative Design leverages AI algorithms to create multiple design alternatives based on constraints and performance criteria. Integrating DFM with AI-powered generative design accelerates innovation by ensuring manufacturable, cost-effective, and high-performance products through automated iterations and real-time manufacturability feedback.

Generative Lattice Structures

Generative lattice structures optimize material usage and enhance mechanical performance by leveraging algorithm-driven design processes that create complex, lightweight geometries unattainable through traditional Design for Manufacturability (DfM). These structures enable advanced manufacturing techniques like additive manufacturing to produce intricate internal frameworks, improving strength-to-weight ratios and reducing production costs.

Automated Manufacturability Analysis

Automated manufacturability analysis in Design for Manufacturability (DFM) leverages predefined rules and historical data to identify potential production issues early, ensuring efficient and cost-effective manufacturing processes. Generative design enhances this approach by using AI-driven algorithms to optimize part geometry for manufacturability constraints, accelerating iteration cycles and enabling innovative solutions tailored to specific fabrication methods.

Constraint-driven Design

Design for Manufacturability (DfM) emphasizes optimizing product designs to meet manufacturing constraints, reducing production costs and improving efficiency by ensuring designs are compatible with existing manufacturing processes. Generative Design leverages algorithm-driven, constraint-driven design approaches to explore multiple feasible solutions rapidly, balancing performance requirements with manufacturing limitations to innovate complex and optimized structures.

Additive Design Validation

Design for Manufacturability (DFM) prioritizes optimizing product designs to align with existing manufacturing constraints and processes, ensuring cost-effectiveness and ease of production. In contrast, Generative Design leverages advanced algorithms to explore innovative geometries, with Additive Design Validation playing a crucial role in verifying these complex structures for feasibility within 3D printing and other additive manufacturing techniques.

Topology Optimization

Design for Manufacturability (DFM) emphasizes simplifying product features to reduce production costs and improve assembly efficiency, while Generative Design leverages algorithms to explore multiple design iterations based on performance criteria. Topology Optimization, a key aspect of Generative Design, reshapes material distribution within a part to enhance structural performance and minimize weight, often surpassing traditional DFM constraints.

Digital Twin-driven DFM

Digital Twin-driven Design for Manufacturability (DFM) integrates real-time data and simulations to optimize production processes, reducing defects and improving efficiency by virtually testing manufacturing scenarios before physical prototyping. Generative Design complements this by using AI algorithms to create multiple design alternatives that meet manufacturability constraints, enabling rapid iteration and innovation within the digital twin environment.

Manufacturability Simulation Loops

Design for Manufacturability (DFM) integrates manufacturability simulation loops early in the product development process to identify and resolve production issues, reducing costs and lead times. Generative Design leverages iterative manufacturability simulations to explore numerous design alternatives, optimizing performance and manufacturability simultaneously through algorithm-driven feedback loops.

Material-aware Generative Algorithms

Material-aware generative design algorithms leverage advanced computational models to optimize product geometry while accounting for specific material properties, enhancing manufacturability and performance simultaneously. Unlike traditional Design for Manufacturability (DFM) techniques that focus on simplifying designs for existing processes, these algorithms enable innovation by integrating material behavior directly into the design workflow, reducing waste and improving structural efficiency.

Design for Manufacturability vs Generative Design Infographic

industrydif.com

industrydif.com