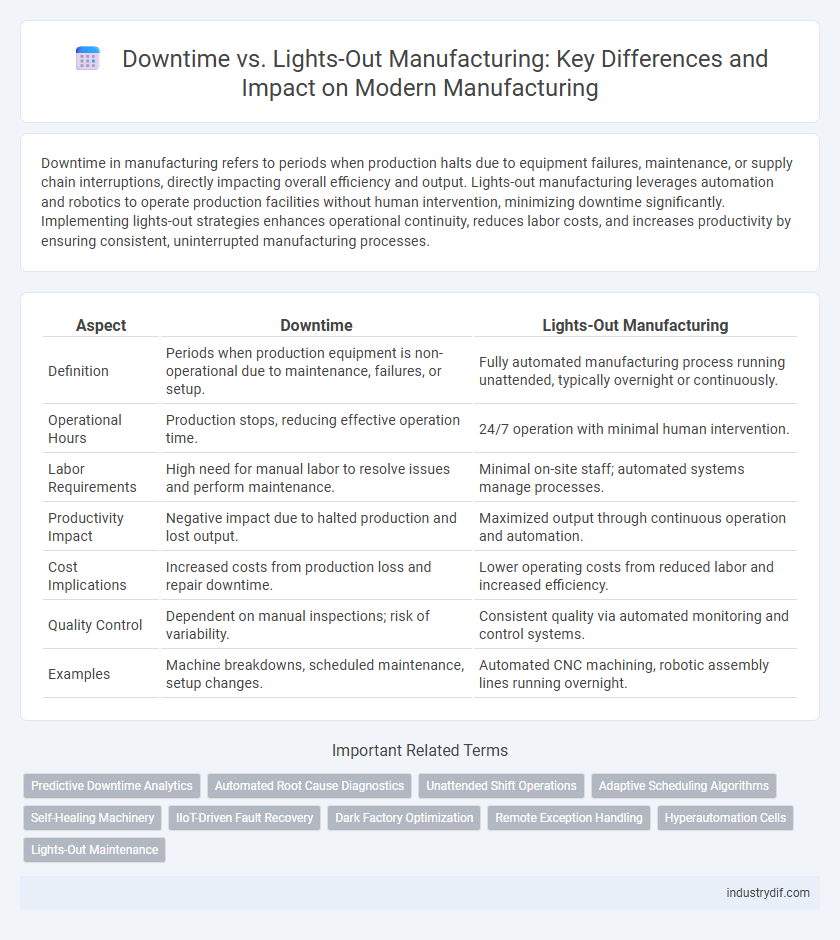

Downtime in manufacturing refers to periods when production halts due to equipment failures, maintenance, or supply chain interruptions, directly impacting overall efficiency and output. Lights-out manufacturing leverages automation and robotics to operate production facilities without human intervention, minimizing downtime significantly. Implementing lights-out strategies enhances operational continuity, reduces labor costs, and increases productivity by ensuring consistent, uninterrupted manufacturing processes.

Table of Comparison

| Aspect | Downtime | Lights-Out Manufacturing |

|---|---|---|

| Definition | Periods when production equipment is non-operational due to maintenance, failures, or setup. | Fully automated manufacturing process running unattended, typically overnight or continuously. |

| Operational Hours | Production stops, reducing effective operation time. | 24/7 operation with minimal human intervention. |

| Labor Requirements | High need for manual labor to resolve issues and perform maintenance. | Minimal on-site staff; automated systems manage processes. |

| Productivity Impact | Negative impact due to halted production and lost output. | Maximized output through continuous operation and automation. |

| Cost Implications | Increased costs from production loss and repair downtime. | Lower operating costs from reduced labor and increased efficiency. |

| Quality Control | Dependent on manual inspections; risk of variability. | Consistent quality via automated monitoring and control systems. |

| Examples | Machine breakdowns, scheduled maintenance, setup changes. | Automated CNC machining, robotic assembly lines running overnight. |

Understanding Downtime in Manufacturing

Downtime in manufacturing refers to periods when production equipment is not operational, leading to decreased productivity and increased operational costs. It can result from equipment failure, maintenance, or supply chain disruptions, severely impacting manufacturing efficiency. Understanding the causes and minimizing downtime is crucial for achieving the continuous operation goals of lights-out manufacturing systems.

Defining Lights-Out Manufacturing

Lights-out manufacturing refers to fully automated production processes that operate without human intervention, significantly reducing downtime caused by manual tasks, shift changes, or human error. This method leverages advanced robotics, AI, and real-time monitoring systems to maintain continuous operations and maximize efficiency. By eliminating the need for on-site personnel, lights-out manufacturing enhances productivity while minimizing production interruptions and operational costs.

Key Differences Between Downtime and Lights-Out Operations

Downtime in manufacturing refers to periods when equipment or production lines are non-operational due to maintenance, failures, or changeovers, leading to reduced productivity. Lights-out manufacturing is a fully automated production environment that operates without human intervention, minimizing downtime by leveraging robotics and IoT technologies. The key difference lies in operational continuity: downtime represents unplanned or planned halts, whereas lights-out manufacturing aims for continuous, uninterrupted production through advanced automation.

Causes and Impacts of Downtime

Downtime in manufacturing often results from equipment failure, maintenance issues, or supply chain disruptions, leading to halted production and increased operational costs. Its impacts include reduced throughput, delayed order fulfillment, and higher labor expenses due to idle workers. Lights-out manufacturing, designed for unattended operation, minimizes downtime by leveraging automation, predictive maintenance, and real-time monitoring systems.

Benefits of Lights-Out Manufacturing Automation

Lights-out manufacturing automation drastically reduces downtime by enabling continuous, unattended production through advanced robotics and AI-driven systems. This approach minimizes human error, improves operational efficiency, and maximizes equipment utilization, leading to substantial cost savings. Enhanced predictive maintenance and real-time monitoring further optimize workflow, ensuring consistent output and quality in manufacturing processes.

Technology Enablers for Lights-Out Manufacturing

Advanced sensors, AI-driven predictive maintenance, and robotics serve as critical technology enablers for lights-out manufacturing, drastically reducing downtime by automating monitoring and operational tasks. Machine learning algorithms analyze real-time data to anticipate equipment failures before they occur, minimizing unplanned stoppages. Integration of IoT devices facilitates seamless communication between machines, allowing continuous production without human intervention.

Strategies to Minimize Downtime

Effective strategies to minimize downtime in manufacturing involve implementing predictive maintenance systems that leverage IoT sensors and AI analytics to foresee equipment failures before they occur. Lights-out manufacturing optimizes this approach by enabling fully automated operations, reducing human intervention and operational interruptions. Integrating real-time monitoring with advanced scheduling algorithms ensures continuous production flow and rapid response to any anomalies, significantly boosting overall equipment effectiveness (OEE).

Challenges in Implementing Lights-Out Manufacturing

Implementing lights-out manufacturing faces significant challenges such as maintaining equipment reliability and addressing unexpected machine failures without on-site human intervention. Advanced automation and real-time monitoring systems are essential to minimize downtime, but integrating these technologies requires substantial investment and skilled workforce adaptation. Furthermore, ensuring cybersecurity in fully autonomous operations is critical to prevent disruptions and maintain continuous production flow.

Cost-Savings Analysis: Downtime vs Lights-Out

Downtime in manufacturing leads to significant cost losses due to halted production lines, labor inefficiencies, and maintenance expenses, often exceeding thousands of dollars per hour depending on the sector. Lights-out manufacturing drastically reduces these costs by enabling fully automated, 24/7 operations with minimal human intervention, cutting energy use and enhancing asset utilization rates. Cost-saving analysis reveals that transitioning to lights-out manufacturing can increase overall equipment effectiveness (OEE) by up to 30%, resulting in substantial long-term financial benefits for manufacturers.

Future Trends in Automated Manufacturing Operations

Downtime reduction remains a critical focus in future automated manufacturing, with advanced predictive maintenance technologies enabling real-time monitoring and minimizing unplanned interruptions. Lights-out manufacturing, characterized by fully unattended operations, is expected to expand through AI-driven robotics and IoT integration, enhancing productivity and operational efficiency. Smart factories equipped with machine learning algorithms will leverage data analytics to optimize workflow, reduce energy consumption, and achieve near-zero downtime environments.

Related Important Terms

Predictive Downtime Analytics

Predictive downtime analytics leverages real-time data and machine learning algorithms to identify potential equipment failures before they occur, enabling a shift from reactive to proactive maintenance in manufacturing. This approach significantly reduces unplanned downtime by optimizing production schedules and facilitating seamless integration with lights-out manufacturing systems for enhanced operational efficiency.

Automated Root Cause Diagnostics

Downtime in manufacturing significantly impacts productivity and operational efficiency, with automated root cause diagnostics playing a crucial role in minimizing unplanned stoppages by quickly identifying underlying issues. Lights-Out Manufacturing leverages these advanced diagnostic systems to enable fully autonomous operations, reducing downtime and improving continuous production through real-time data analysis and rapid fault resolution.

Unattended Shift Operations

Unattended shift operations in lights-out manufacturing minimize downtime by enabling continuous, automated production without human intervention, drastically improving operational efficiency and reducing labor costs. Integrating advanced monitoring systems and predictive maintenance ensures rapid response to equipment failures, further limiting unplanned downtime and maximizing uptime during unattended shifts.

Adaptive Scheduling Algorithms

Adaptive scheduling algorithms in manufacturing optimize production by minimizing downtime through real-time adjustments to machine operations and workflow sequences. These algorithms enable seamless transition to lights-out manufacturing by autonomously managing schedules, equipment maintenance, and resource allocation to maintain continuous, unmanned production.

Self-Healing Machinery

Self-healing machinery significantly reduces downtime by autonomously detecting, diagnosing, and repairing faults, ensuring continuous operation in lights-out manufacturing environments. These advanced systems leverage AI-driven predictive maintenance and real-time monitoring to enhance production efficiency and minimize manual intervention.

IIoT-Driven Fault Recovery

IIoT-driven fault recovery minimizes downtime in manufacturing by enabling real-time monitoring and predictive maintenance, leading to faster detection and resolution of equipment failures. Lights-out manufacturing leverages advanced automation and IIoT analytics to support continuous, unattended production, significantly reducing manual intervention and unplanned downtime.

Dark Factory Optimization

Dark factory optimization minimizes downtime by employing automated systems and real-time monitoring to maintain continuous production without human intervention. Leveraging predictive maintenance and AI-driven analytics enhances operational efficiency, reduces unexpected halts, and maximizes output in lights-out manufacturing environments.

Remote Exception Handling

Remote exception handling in lights-out manufacturing drastically reduces downtime by enabling real-time monitoring and automated issue resolution without human intervention. Advanced IoT sensors and AI-driven analytics detect anomalies instantly, allowing for swift corrective actions that maintain continuous production flow.

Hyperautomation Cells

Hyperautomation cells minimize downtime by integrating AI-driven robotics and real-time analytics to enable seamless lights-out manufacturing operations. This advanced automation framework enhances productivity and reduces human intervention by continuously monitoring equipment health and autonomously adjusting processes.

Lights-Out Maintenance

Lights-out manufacturing maximizes operational efficiency by enabling continuous production with minimal human intervention, effectively reducing downtime caused by manual maintenance tasks. Implementing lights-out maintenance leverages automated monitoring systems and predictive analytics to preempt equipment failures, ensuring seamless, uninterrupted manufacturing processes.

Downtime vs Lights-Out Manufacturing Infographic

industrydif.com

industrydif.com