Workstations provide controlled environments where tasks are performed manually or with minimal automation, ensuring precision and consistency in manufacturing processes. Collaborative robots, or cobots, work alongside human operators, enhancing flexibility and productivity by automating repetitive or hazardous tasks while allowing seamless human-robot interaction. Integrating cobots into traditional workstations boosts efficiency, reduces labor strain, and accelerates production cycles without compromising safety.

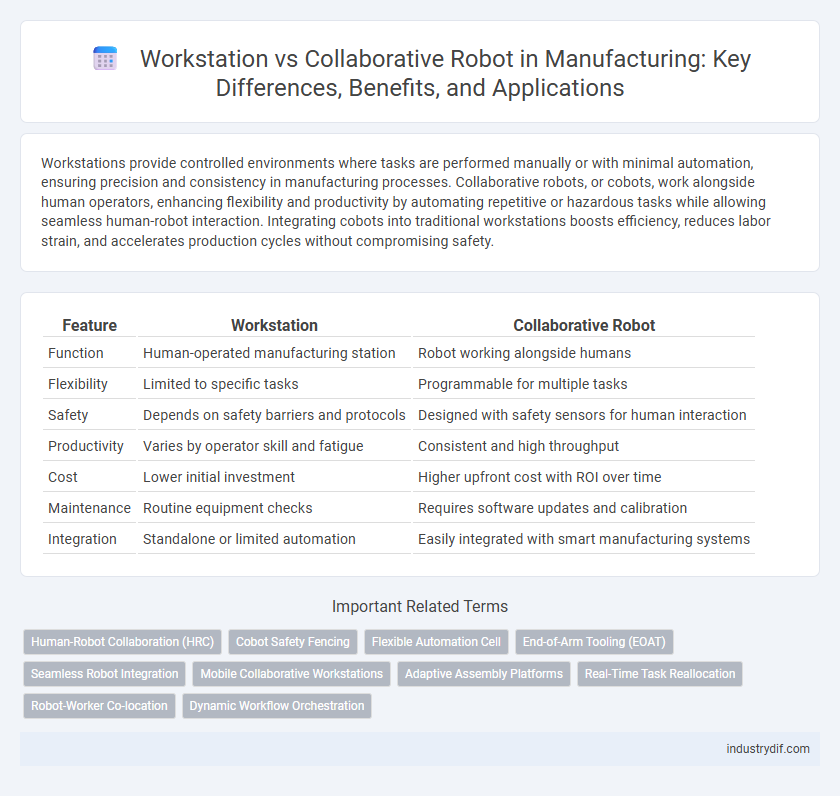

Table of Comparison

| Feature | Workstation | Collaborative Robot |

|---|---|---|

| Function | Human-operated manufacturing station | Robot working alongside humans |

| Flexibility | Limited to specific tasks | Programmable for multiple tasks |

| Safety | Depends on safety barriers and protocols | Designed with safety sensors for human interaction |

| Productivity | Varies by operator skill and fatigue | Consistent and high throughput |

| Cost | Lower initial investment | Higher upfront cost with ROI over time |

| Maintenance | Routine equipment checks | Requires software updates and calibration |

| Integration | Standalone or limited automation | Easily integrated with smart manufacturing systems |

Defining Workstations in Modern Manufacturing

Workstations in modern manufacturing serve as designated areas equipped with specialized tools and machinery designed to optimize human productivity and precision in repetitive tasks. These setups often integrate ergonomic designs and safety features to enhance operator efficiency while minimizing fatigue and injury risks. Unlike collaborative robots, workstations rely primarily on human skill and manual intervention, making them vital for tasks requiring complex decision-making or fine motor control.

What Are Collaborative Robots (Cobots)?

Collaborative robots (cobots) are designed to work safely alongside human operators in manufacturing environments, enhancing productivity without the need for extensive safety barriers. Unlike traditional industrial robots confined to fixed workstations for repetitive tasks, cobots offer flexibility and adaptability, allowing seamless human-robot collaboration for assembly, quality inspection, and material handling. Their built-in sensors and advanced programming enable real-time responsiveness, reducing workplace injuries and optimizing workflow efficiency on the production floor.

Key Differences Between Workstations and Cobots

Workstations in manufacturing are fixed setups designed for specific tasks, emphasizing human operator control and manual processes, whereas collaborative robots (cobots) are flexible, programmable machines engineered to work safely alongside humans. Cobots enhance productivity by automating repetitive or hazardous tasks while allowing human workers to focus on complex activities, unlike traditional workstations that limit adaptability. Integration of cobots improves workflow efficiency and reduces ergonomic risks, offering scalability that stationary workstations cannot match.

Flexibility and Adaptability in Industrial Settings

Workstations offer fixed functionality optimized for specific tasks, ensuring consistent output but limited flexibility in industrial environments. Collaborative robots (cobots) provide adaptive automation with programmable features that easily adjust to varied production requirements and workspace changes. Their ability to safely work alongside human operators enhances operational versatility and supports dynamic manufacturing processes.

Safety Considerations: Workstations vs Cobots

Workstations in manufacturing environments require extensive safety measures such as physical barriers and emergency stop systems to protect operators from heavy machinery risks. Collaborative robots (cobots) are designed with integrated sensors and force-limiting technology to safely interact with human workers without the need for extensive guarding. Implementing cobots can reduce workplace injuries and improve compliance with OSHA safety standards while maintaining efficient production workflows.

Productivity and Throughput Comparison

Workstations typically optimize productivity through dedicated human skills and flexible task management, while collaborative robots (cobots) enhance throughput by performing repetitive tasks with consistent precision and speed. Cobots reduce cycle times and minimize human error, leading to improved overall equipment effectiveness (OEE) and higher throughput rates in manufacturing lines. Integrating cobots alongside workstations can balance efficiency and adaptability, maximizing productivity in dynamic production environments.

Space Utilization and Factory Layout

Workstations are fixed areas designed to optimize human task efficiency, often requiring significant floor space for operator movement and tool accessibility, which can limit factory layout flexibility. Collaborative robots (cobots) enhance space utilization by operating safely alongside workers in compact zones, enabling more dynamic and modular factory layouts. This integration allows manufacturers to increase productivity without extensive reconfiguration or expansion of physical workspace.

Integration with Existing Manufacturing Systems

Workstations are traditionally designed for specific manufacturing tasks with limited flexibility in integration, relying heavily on manual operation and separate control systems. Collaborative robots (cobots) seamlessly integrate with existing manufacturing execution systems (MES) and programmable logic controllers (PLCs), enabling real-time data exchange and adaptive automation. This integration enhances production efficiency by synchronizing human-robot interactions within the digital manufacturing ecosystem.

Cost-Benefit Analysis: Upfront and Operational

Workstations typically require higher upfront investments for equipment and consistent operational costs due to manual labor wages and maintenance. Collaborative robots (cobots) often involve a moderate initial expense but reduce long-term operational costs by increasing efficiency, minimizing errors, and lowering labor costs through automation. Cost-benefit analysis reveals that cobots provide enhanced ROI in production environments with repetitive tasks and scalability needs, while traditional workstations may suit low-volume or highly customized manufacturing.

Future Trends: Human Workstations and Cobots Collaboration

Future manufacturing trends emphasize seamless integration between human workstations and collaborative robots (cobots) to enhance productivity and safety. Advanced sensor technologies and AI-driven systems enable cobots to adapt dynamically to human actions, creating flexible and efficient production environments. This synergy between human dexterity and robotic precision is poised to revolutionize smart factories, optimizing workflows and minimizing downtime.

Related Important Terms

Human-Robot Collaboration (HRC)

Human-Robot Collaboration (HRC) in manufacturing enhances productivity by integrating collaborative robots (cobots) that safely work alongside humans at workstations without extensive safety barriers, enabling flexible and adaptive task sharing. Unlike traditional isolated robot workstations, HRC systems leverage advanced sensors and AI to facilitate real-time communication and ergonomic support, improving precision and reducing operator fatigue.

Cobot Safety Fencing

Workstations equipped with traditional safety fencing limit operator mobility and flexibility, whereas collaborative robots (cobots) utilize advanced sensors and lightweight barriers that enhance safety while allowing seamless human-robot interaction. Innovative cobot safety fencing designs prioritize proximity detection and force limitation, ensuring compliance with ISO 10218 and ISO/TS 15066 standards for safe collaborative manufacturing environments.

Flexible Automation Cell

Flexible automation cells integrate workstations and collaborative robots to enhance manufacturing efficiency by enabling rapid reconfiguration and seamless human-robot interaction. Collaborative robots adapt to diverse tasks within the cell, increasing productivity while workstations provide specialized manual operations, creating a versatile production environment.

End-of-Arm Tooling (EOAT)

End-of-Arm Tooling (EOAT) in manufacturing varies significantly between workstations and collaborative robots, with workstations typically utilizing fixed, task-specific EOAT for high precision and repeatability, while collaborative robots employ adaptable, modular EOAT designed for flexibility and safe human interaction. Investing in EOAT technology tailored to collaborative robots enhances automation versatility and supports diverse assembly tasks, compared to the specialized but less flexible tooling found in traditional workstations.

Seamless Robot Integration

Seamless robot integration in manufacturing enhances productivity by enabling collaborative robots to work safely alongside human operators within the same workstation, reducing downtime and increasing operational efficiency. Workstations designed for collaborative robots incorporate ergonomic layouts and advanced sensor technologies, ensuring smooth interaction and optimized task automation.

Mobile Collaborative Workstations

Mobile collaborative workstations integrate advanced robotic arms with human operators, optimizing flexibility and productivity on manufacturing floors. These systems enhance task precision and reduce operator fatigue by combining autonomous mobility with real-time human-robot interaction, outperforming traditional fixed workstations and standard collaborative robots.

Adaptive Assembly Platforms

Adaptive assembly platforms integrate workstations with collaborative robots to enhance flexibility and precision in manufacturing processes. These systems optimize task allocation, allowing robots to handle repetitive actions while human operators focus on complex, decision-intensive tasks, resulting in improved productivity and reduced downtime.

Real-Time Task Reallocation

Workstations provide fixed, manual task assignments with limited flexibility, whereas collaborative robots enable real-time task reallocation through adaptive automation and sensor-driven responsiveness. This dynamic adjustment enhances production efficiency by allowing seamless shifts in workload distribution based on immediate operational demands.

Robot-Worker Co-location

Workstation designs that enable robot-worker co-location improve manufacturing efficiency by integrating collaborative robots (cobots) directly alongside human operators, enhancing real-time task sharing and reducing cycle times. Cobots equipped with advanced sensors and safety features allow safe, close-proximity interactions, minimizing workspace segregation and fostering seamless human-robot collaboration on assembly lines.

Dynamic Workflow Orchestration

Workstations provide fixed, task-specific operations while collaborative robots enable dynamic workflow orchestration by seamlessly adapting to changing production demands and integrating with human workers in real-time. This flexibility optimizes manufacturing efficiency, reduces cycle times, and enhances productivity through synchronized human-robot interaction.

Workstation vs Collaborative Robot Infographic

industrydif.com

industrydif.com