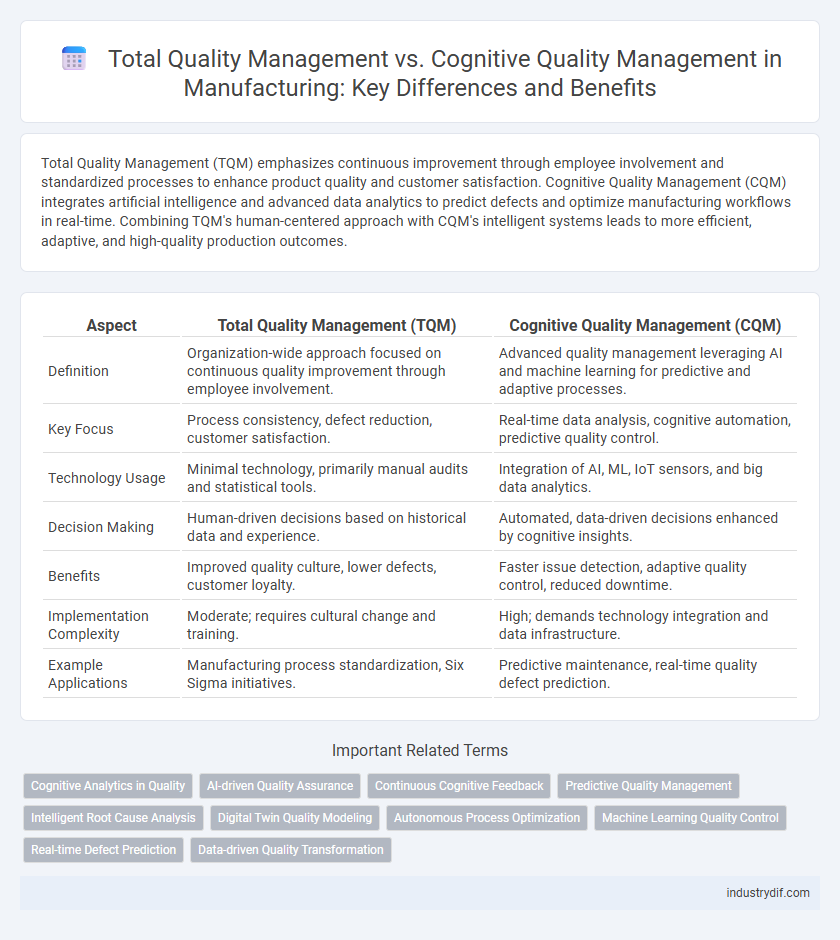

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and standardized processes to enhance product quality and customer satisfaction. Cognitive Quality Management (CQM) integrates artificial intelligence and advanced data analytics to predict defects and optimize manufacturing workflows in real-time. Combining TQM's human-centered approach with CQM's intelligent systems leads to more efficient, adaptive, and high-quality production outcomes.

Table of Comparison

| Aspect | Total Quality Management (TQM) | Cognitive Quality Management (CQM) |

|---|---|---|

| Definition | Organization-wide approach focused on continuous quality improvement through employee involvement. | Advanced quality management leveraging AI and machine learning for predictive and adaptive processes. |

| Key Focus | Process consistency, defect reduction, customer satisfaction. | Real-time data analysis, cognitive automation, predictive quality control. |

| Technology Usage | Minimal technology, primarily manual audits and statistical tools. | Integration of AI, ML, IoT sensors, and big data analytics. |

| Decision Making | Human-driven decisions based on historical data and experience. | Automated, data-driven decisions enhanced by cognitive insights. |

| Benefits | Improved quality culture, lower defects, customer loyalty. | Faster issue detection, adaptive quality control, reduced downtime. |

| Implementation Complexity | Moderate; requires cultural change and training. | High; demands technology integration and data infrastructure. |

| Example Applications | Manufacturing process standardization, Six Sigma initiatives. | Predictive maintenance, real-time quality defect prediction. |

Introduction to Quality Management in Manufacturing

Total Quality Management (TQM) in manufacturing emphasizes continuous improvement, employee involvement, and customer focus to enhance product quality and operational efficiency. Cognitive Quality Management integrates artificial intelligence and machine learning to analyze production data, predict defects, and optimize quality processes in real-time. Combining traditional TQM principles with cognitive technologies enables manufacturers to achieve higher accuracy, reduce waste, and accelerate decision-making in quality assurance.

Defining Total Quality Management (TQM)

Total Quality Management (TQM) in manufacturing is a comprehensive approach focused on continuous improvement of processes, products, and services to achieve long-term customer satisfaction. It relies on the involvement of all employees, systematic measurement, and data-driven decision-making to enhance quality at every production stage. TQM emphasizes defect prevention, process standardization, and aligning organizational objectives with customer expectations to reduce costs and improve operational efficiency.

Key Principles of TQM in Manufacturing

Total Quality Management (TQM) in manufacturing emphasizes customer focus, continuous improvement, and employee involvement to enhance product quality and operational efficiency. Key principles include process-centered approaches, integrated system management, fact-based decision making, and strategic quality planning to reduce defects and increase customer satisfaction. TQM fosters a culture where every employee is responsible for quality, driving consistent improvements throughout the manufacturing lifecycle.

Introduction to Cognitive Quality Management (CQM)

Cognitive Quality Management (CQM) integrates advanced artificial intelligence and machine learning technologies to enhance traditional Total Quality Management (TQM) frameworks in manufacturing. By leveraging real-time data analytics and cognitive algorithms, CQM enables predictive quality control and adaptive process optimization, reducing defects and operational costs. This innovative approach transforms quality management from reactive inspection to proactive, intelligent decision-making, driving continuous improvement and competitive advantage.

Core Concepts of CQM in the Manufacturing Sector

Core concepts of Cognitive Quality Management (CQM) in manufacturing include the integration of artificial intelligence and machine learning to enhance decision-making processes, real-time data analysis for predictive maintenance, and adaptive quality control systems that continuously learn from production feedback. CQM emphasizes cognitive automation, enabling smart machines to detect defects and optimize operations autonomously, surpassing traditional Total Quality Management (TQM) approaches. This leads to improved product consistency, reduced downtime, and higher responsiveness to changing manufacturing conditions.

TQM vs CQM: Key Differences and Similarities

Total Quality Management (TQM) focuses on continuous improvement through employee involvement, process optimization, and customer satisfaction, emphasizing defect prevention and quality control across all organizational levels. Cognitive Quality Management (CQM) integrates artificial intelligence and machine learning to analyze data, predict quality issues, and enable proactive decision-making, enhancing real-time process adjustments. Both TQM and CQM aim to improve product quality and operational efficiency but differ in their reliance on human-centric versus technology-driven approaches for quality enhancement.

Impact of TQM on Manufacturing Efficiency

Total Quality Management (TQM) significantly improves manufacturing efficiency by reducing defects, minimizing waste, and enhancing process consistency through continuous improvement and employee involvement. The implementation of TQM practices leads to higher product quality, lower production costs, and increased customer satisfaction in manufacturing settings. Compared to Cognitive Quality Management, TQM emphasizes systematic quality control and collaborative problem-solving, directly impacting operational performance and resource optimization.

Advantages of Implementing CQM in Modern Manufacturing

Implementing Cognitive Quality Management (CQM) in modern manufacturing enhances decision-making through AI-driven data analysis, enabling real-time quality control and predictive maintenance that reduce downtime and defects. CQM systems leverage machine learning to continuously improve processes by identifying subtle patterns and root causes invisible to traditional Total Quality Management (TQM) methods. This integration of cognitive technologies leads to accelerated innovation, higher product consistency, and increased operational efficiency critical for competitive advantage in Industry 4.0 environments.

Integration Challenges: Transitioning from TQM to CQM

Transitioning from Total Quality Management (TQM) to Cognitive Quality Management (CQM) presents integration challenges primarily due to the shift from traditional process control to AI-driven decision-making. Manufacturing systems must seamlessly incorporate machine learning algorithms and data analytics while maintaining existing quality standards and employee engagement. Overcoming resistance to change and ensuring interoperability between legacy TQM frameworks and advanced CQM technologies are critical for successful adoption.

Future Trends: Evolving Quality Paradigms in Manufacturing

Future trends in manufacturing highlight the shift from Total Quality Management (TQM) to Cognitive Quality Management (CQM), emphasizing AI-driven predictive analytics and real-time adaptive control systems. Cognitive Quality Management leverages machine learning algorithms to enhance defect detection and process optimization, outperforming traditional TQM's reactive approaches. Integration of IoT sensors and big data enables a dynamic quality assurance ecosystem, promoting continuous improvement and smarter decision-making in manufacturing processes.

Related Important Terms

Cognitive Analytics in Quality

Cognitive Quality Management leverages advanced cognitive analytics to enhance defect detection, root cause analysis, and predictive maintenance, surpassing traditional Total Quality Management's reliance on manual inspection and statistical methods. Integrating AI-driven data interpretation accelerates decision-making and optimizes production processes, leading to higher product consistency and reduced downtime in manufacturing environments.

AI-driven Quality Assurance

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and process control, while Cognitive Quality Management leverages AI-driven quality assurance to enhance defect detection, predictive maintenance, and real-time decision-making. AI algorithms enable advanced data analytics and pattern recognition, significantly increasing manufacturing accuracy and reducing operational downtime compared to traditional TQM approaches.

Continuous Cognitive Feedback

Total Quality Management (TQM) emphasizes systematic processes and employee involvement to achieve consistent product quality, while Cognitive Quality Management (CQM) integrates continuous cognitive feedback through real-time data analytics and machine learning to enhance decision-making and adapt processes dynamically. Continuous cognitive feedback in CQM enables proactive identification of quality issues and personalized improvements, driving higher efficiency and innovation in manufacturing operations.

Predictive Quality Management

Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction through standardized processes, while Cognitive Quality Management (CQM) integrates artificial intelligence and machine learning to enable Predictive Quality Management by analyzing real-time manufacturing data and anticipating defects before they occur. Predictive Quality Management leverages advanced analytics and cognitive technologies to reduce waste, optimize production efficiency, and ensure higher product reliability in manufacturing operations.

Intelligent Root Cause Analysis

Total Quality Management (TQM) traditionally emphasizes process improvement through systematic audits and employee involvement, while Cognitive Quality Management leverages advanced AI algorithms to perform Intelligent Root Cause Analysis, facilitating faster detection and resolution of defects. Integrating machine learning models in Cognitive Quality Management enhances predictive maintenance and real-time decision-making, significantly reducing downtime and operational costs compared to conventional TQM approaches.

Digital Twin Quality Modeling

Total Quality Management emphasizes continuous improvement through standardized processes and employee involvement, while Cognitive Quality Management leverages AI-driven Digital Twin Quality Modeling to simulate, predict, and optimize manufacturing outcomes in real-time. Digital Twin Quality Modeling enables proactive defect detection, adaptive process adjustments, and enhanced predictive maintenance, significantly improving product quality and operational efficiency.

Autonomous Process Optimization

Total Quality Management (TQM) emphasizes standardized procedures and continuous improvement through collective employee involvement, while Cognitive Quality Management (CQM) leverages AI-driven analytics and machine learning to enable autonomous process optimization, reducing human intervention and increasing predictive accuracy. Autonomous process optimization in CQM dynamically adjusts manufacturing parameters in real-time, enhancing product consistency, minimizing defects, and accelerating decision-making compared to traditional TQM methodologies.

Machine Learning Quality Control

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and statistical process control, whereas Cognitive Quality Management (CQM) integrates machine learning algorithms to analyze real-time data for predictive quality control, reducing defects and downtime. Leveraging advanced AI models enables manufacturers to detect patterns and anomalies beyond human capability, optimizing production processes and enhancing product reliability.

Real-time Defect Prediction

Total Quality Management (TQM) emphasizes continuous improvement and process control to reduce defects, while Cognitive Quality Management harnesses AI and machine learning for real-time defect prediction, enabling proactive adjustments during production. Real-time defect prediction using cognitive systems enhances manufacturing efficiency by identifying potential quality issues before they escalate, reducing waste and downtime.

Data-driven Quality Transformation

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and standardized processes, while Cognitive Quality Management (CQM) leverages artificial intelligence and machine learning to analyze complex data patterns for predictive quality control. Data-driven quality transformation in manufacturing accelerates defect detection and process optimization by integrating real-time analytics and cognitive computing, significantly enhancing product reliability and operational efficiency.

Total Quality Management vs Cognitive Quality Management Infographic

industrydif.com

industrydif.com