Manufacturing strategies increasingly prioritize the circular economy to minimize waste and maximize resource efficiency compared to traditional supply chain models focused on linear resource flow. Circular economy approaches integrate recycling, remanufacturing, and reuse at every stage to create closed-loop systems that reduce environmental impact and lower costs. This shift drives innovation in supply chain management by emphasizing sustainability and long-term resilience over short-term gains.

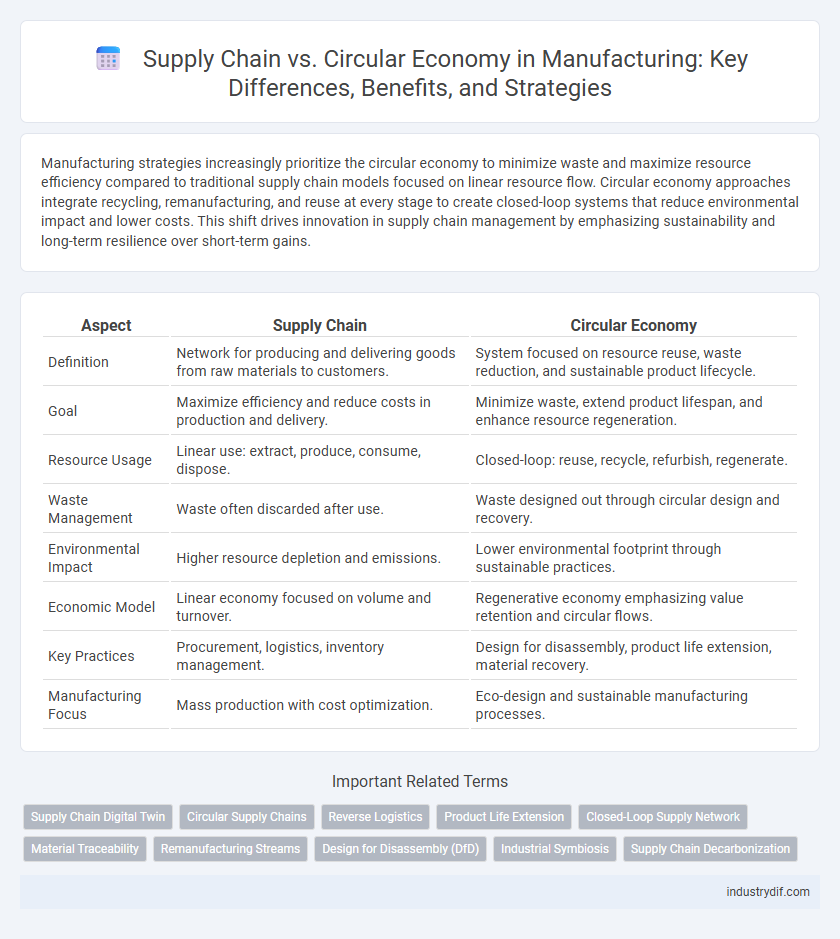

Table of Comparison

| Aspect | Supply Chain | Circular Economy |

|---|---|---|

| Definition | Network for producing and delivering goods from raw materials to customers. | System focused on resource reuse, waste reduction, and sustainable product lifecycle. |

| Goal | Maximize efficiency and reduce costs in production and delivery. | Minimize waste, extend product lifespan, and enhance resource regeneration. |

| Resource Usage | Linear use: extract, produce, consume, dispose. | Closed-loop: reuse, recycle, refurbish, regenerate. |

| Waste Management | Waste often discarded after use. | Waste designed out through circular design and recovery. |

| Environmental Impact | Higher resource depletion and emissions. | Lower environmental footprint through sustainable practices. |

| Economic Model | Linear economy focused on volume and turnover. | Regenerative economy emphasizing value retention and circular flows. |

| Key Practices | Procurement, logistics, inventory management. | Design for disassembly, product life extension, material recovery. |

| Manufacturing Focus | Mass production with cost optimization. | Eco-design and sustainable manufacturing processes. |

Understanding Supply Chain in Manufacturing

Understanding supply chain in manufacturing involves managing the flow of raw materials, components, and finished products through sourcing, production, and distribution processes. Effective supply chain management enhances operational efficiency, reduces costs, and ensures timely delivery by integrating procurement, inventory management, and logistics. Emphasizing transparency and collaboration with suppliers supports sustainable practices aligning with circular economy principles.

Key Principles of the Circular Economy

The circular economy in manufacturing emphasizes designing products for longevity, reparability, and recyclability to minimize waste and maximize resource efficiency. Key principles include maintaining material value through reuse, remanufacturing, and recycling processes while reducing dependency on virgin raw materials. This approach contrasts with traditional linear supply chains by closing loops and promoting sustainable resource management throughout production and consumption cycles.

Linear Supply Chain vs Circular Economy: Core Differences

Linear supply chain in manufacturing follows a straightforward process of raw material extraction, production, and disposal, resulting in significant resource depletion and waste generation. Circular economy emphasizes resource regeneration, waste minimization, and product lifecycle extension through recycling, remanufacturing, and reuse initiatives. Core differences lie in linear models prioritizing throughput and efficiency, whereas circular systems optimize sustainability and environmental impact by closing material loops.

Raw Material Sourcing: Traditional vs Circular Approaches

Traditional raw material sourcing in manufacturing relies heavily on extracting finite resources, often leading to significant environmental degradation and supply chain vulnerabilities. Circular economy approaches prioritize reutilizing materials through recycling, remanufacturing, and sustainable sourcing to create closed-loop systems that minimize waste and reduce dependency on virgin resources. Emphasizing circular raw material sourcing enhances resource efficiency, lowers carbon emissions, and promotes long-term supply chain resilience.

Impact on Manufacturing Efficiency and Sustainability

Supply chain optimization enhances manufacturing efficiency by streamlining procurement, reducing lead times, and lowering operational costs through improved logistics and inventory management. In contrast, circular economy principles drive sustainability by promoting resource reuse, waste reduction, and product lifecycle extension, which can initially challenge efficiency but ultimately lead to resilient manufacturing models. Integrating circular economy practices within supply chains creates a balanced approach that improves long-term manufacturing sustainability while maintaining operational efficiency.

Waste Management Strategies in Both Models

Supply chain strategies in manufacturing prioritize efficient resource allocation and minimizing production delays, often focusing on linear waste management practices like disposal or incineration. Circular economy models emphasize waste reduction through reuse, recycling, and remanufacturing to create closed-loop systems that extend product life cycles and reduce raw material dependence. Integrating circular waste management strategies improves sustainability by transforming waste into valuable inputs, contrasting with traditional supply chain approaches that typically generate higher levels of industrial waste.

Integration of Circular Practices in Modern Supply Chains

Integrating circular economy principles into modern supply chains enhances resource efficiency by promoting reuse, remanufacturing, and recycling processes across manufacturing stages. Companies adopting closed-loop supply chains reduce waste and minimize environmental impact while improving cost savings and supply resilience. Advanced technologies like IoT and blockchain enable transparency and traceability, facilitating effective circular practices integration in supply chain management.

Economic Implications for Manufacturers

Supply chain management in manufacturing emphasizes cost efficiency, timely delivery, and resource optimization, directly impacting profit margins and competitiveness. Transitioning to a circular economy introduces new economic models focused on product lifecycle extension, waste reduction, and resource recirculation, which can lower raw material costs and create new revenue streams. Manufacturers adopting circular practices often face initial investment challenges but benefit from long-term savings, enhanced brand value, and resilience against supply chain disruptions.

Technological Innovations Driving the Transition

Technological innovations such as IoT sensors, blockchain, and AI-driven analytics are transforming supply chain management by enhancing transparency, traceability, and efficiency. These advancements enable manufacturers to optimize resource use, reduce waste, and facilitate product lifecycle tracking, key components of a circular economy. Smart manufacturing systems and digital twins support closed-loop processes, accelerating the transition from linear supply chains to sustainable circular models.

Future Trends: Circular Economy’s Role in Manufacturing

The circular economy is reshaping manufacturing supply chains by emphasizing resource efficiency, waste reduction, and product lifecycle extension. Future trends highlight increased adoption of closed-loop systems, where materials are continuously repurposed, minimizing reliance on virgin resources. Integrating circular principles enhances sustainability, reduces costs, and fosters innovation in product design and supply chain management.

Related Important Terms

Supply Chain Digital Twin

Supply Chain Digital Twins enable real-time simulation and optimization of manufacturing processes, enhancing visibility, efficiency, and resilience across complex supply networks. Integrating these digital replicas supports circular economy goals by minimizing waste, improving resource reuse, and facilitating sustainable production cycles through precise data-driven decision-making.

Circular Supply Chains

Circular supply chains integrate regenerative design and resource recovery processes to reduce waste and maximize material reuse, enhancing sustainability in manufacturing. Emphasizing closed-loop systems, these supply chains optimize resource efficiency, lower environmental impact, and create economic value through continuous product lifecycle management.

Reverse Logistics

Reverse logistics plays a critical role in bridging supply chain efficiency and circular economy objectives by enabling the systematic return, refurbishment, and recycling of products. Integrating reverse logistics within manufacturing supply chains reduces waste, lowers operational costs, and enhances resource recovery, driving sustainable production cycles.

Product Life Extension

Supply chain management in manufacturing traditionally emphasizes efficiency and cost reduction through streamlined logistics and inventory control, whereas the circular economy prioritizes product life extension by designing for durability, repairability, and reuse to minimize waste. Implementing product life extension strategies enhances resource efficiency, reduces environmental impact, and creates new value streams by closing the loop within supply chains.

Closed-Loop Supply Network

A Closed-Loop Supply Network integrates traditional supply chain processes with circular economy principles by emphasizing product reuse, remanufacturing, and recycling to minimize waste and maximize resource efficiency. This model enables manufacturers to recover value from end-of-life products, reducing raw material dependency and enhancing sustainability throughout the entire production cycle.

Material Traceability

Material traceability in manufacturing enhances supply chain transparency by tracking raw materials from origin to finished products, reducing risks of contamination and fraud. Integrating circular economy principles promotes resource recovery and reuse, enabling closed-loop supply chains that improve sustainability and material lifecycle management.

Remanufacturing Streams

Remanufacturing streams in manufacturing enhance supply chain efficiency by reducing raw material dependency and minimizing waste through the reuse of components. Incorporating circular economy principles transforms traditional linear supply chains into sustainable loops that optimize resource recovery and extend product life cycles.

Design for Disassembly (DfD)

Design for Disassembly (DfD) enhances supply chain efficiency by enabling ease of product breakdown for repair, reuse, or recycling, directly supporting circular economy principles. Integrating DfD in manufacturing reduces raw material dependency, minimizes waste, and promotes resource circularity by optimizing end-of-life product recovery and reintegration into production cycles.

Industrial Symbiosis

Industrial symbiosis enhances supply chain efficiency by enabling the exchange of materials, energy, and by-products between manufacturing enterprises, reducing waste and lowering production costs. This collaborative approach within a circular economy model optimizes resource utilization and promotes sustainable manufacturing practices by transforming one industry's outputs into another's inputs.

Supply Chain Decarbonization

Supply chain decarbonization in manufacturing emphasizes reducing greenhouse gas emissions at every stage, from raw material sourcing to product delivery, leveraging renewable energy, energy-efficient logistics, and waste minimization techniques. Integrating circular economy principles, such as resource recovery and product lifecycle extension, enhances supply chain sustainability by closing material loops and minimizing environmental impact.

Supply Chain vs Circular Economy Infographic

industrydif.com

industrydif.com