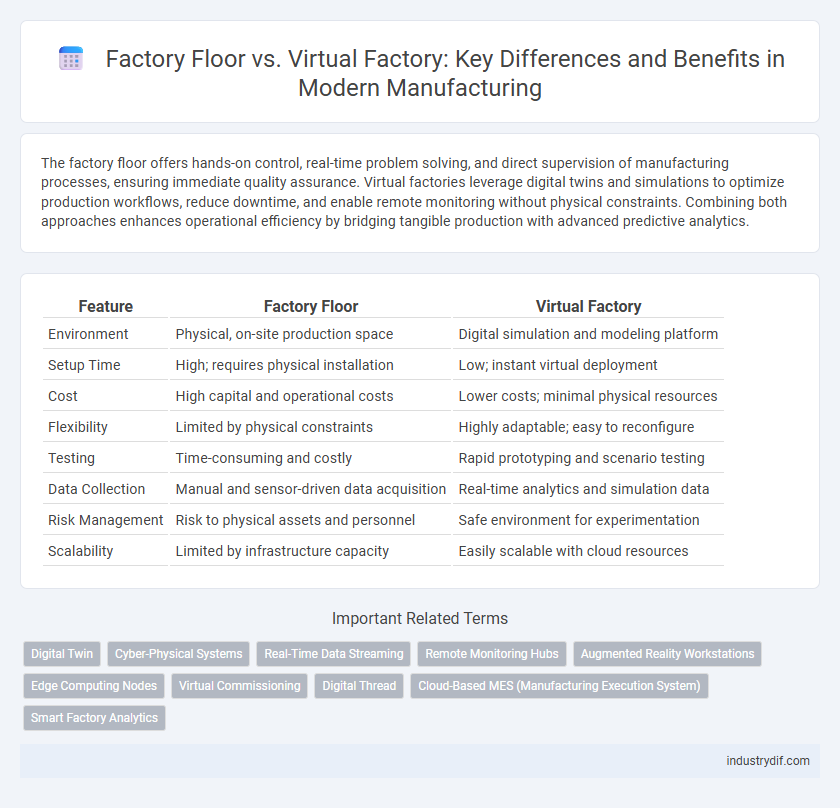

The factory floor offers hands-on control, real-time problem solving, and direct supervision of manufacturing processes, ensuring immediate quality assurance. Virtual factories leverage digital twins and simulations to optimize production workflows, reduce downtime, and enable remote monitoring without physical constraints. Combining both approaches enhances operational efficiency by bridging tangible production with advanced predictive analytics.

Table of Comparison

| Feature | Factory Floor | Virtual Factory |

|---|---|---|

| Environment | Physical, on-site production space | Digital simulation and modeling platform |

| Setup Time | High; requires physical installation | Low; instant virtual deployment |

| Cost | High capital and operational costs | Lower costs; minimal physical resources |

| Flexibility | Limited by physical constraints | Highly adaptable; easy to reconfigure |

| Testing | Time-consuming and costly | Rapid prototyping and scenario testing |

| Data Collection | Manual and sensor-driven data acquisition | Real-time analytics and simulation data |

| Risk Management | Risk to physical assets and personnel | Safe environment for experimentation |

| Scalability | Limited by infrastructure capacity | Easily scalable with cloud resources |

Defining the Factory Floor: Core Concepts

The factory floor represents the physical space where manufacturing operations occur, encompassing machinery, assembly lines, and workforce activities essential for producing goods. Key core concepts include workflow optimization, equipment layout, real-time monitoring, and safety protocols to ensure efficient and secure production processes. Understanding the factory floor's tangible environment is critical for aligning manufacturing strategies with operational performance and quality control.

What is a Virtual Factory?

A virtual factory is a digital replica of a physical manufacturing facility that enables real-time simulation, monitoring, and optimization of production processes using advanced technologies such as IoT, digital twins, and AI. It allows manufacturers to visualize workflows, predict equipment failures, and improve efficiency without disrupting actual operations. Integrating a virtual factory with factory floor data enhances decision-making, reduces downtime, and accelerates product development cycles.

Key Differences: Physical vs Digital Production

Factory floors involve physical production environments where machinery, labor, and raw materials interact to manufacture tangible products, emphasizing hands-on processes and real-time operations. Virtual factories utilize digital simulations and software to replicate these production processes, enabling planning, testing, and optimization without physical constraints. Key differences include the tangible nature of factory floors versus the intangible, model-based approach of virtual factories, driving distinct efficiencies in production scalability and risk management.

Workflow Optimization in Both Environments

Factory floor workflow optimization relies on real-time data from physical equipment and human operators to streamline production processes and reduce bottlenecks. Virtual factory environments utilize digital twins and simulation technologies to test and refine workflows before implementation, minimizing downtime and enhancing resource allocation. Integrating insights from both settings enables comprehensive optimization strategies that improve efficiency and operational agility.

Real-Time Data: IoT on the Factory Floor vs Virtual Monitoring

Real-time data integration on the factory floor utilizes IoT sensors to capture machine performance, environmental conditions, and production metrics, enabling immediate adjustments and predictive maintenance. Virtual factories leverage digital twins and cloud-based platforms to simulate operations, analyze data remotely, and optimize workflows without physical presence. Combining IoT-driven real-time monitoring with virtual factory analytics enhances operational efficiency, reduces downtime, and supports informed decision-making across manufacturing processes.

Workforce Requirements: Skilled Labor vs Digital Operators

Factory floors demand a workforce proficient in hands-on skilled labor, including machine operation, maintenance, and quality control, emphasizing tactile expertise and physical problem-solving. Virtual factories require digital operators skilled in software management, data analysis, and remote system monitoring, highlighting proficiency in automation, AI technologies, and cybersecurity. This shift necessitates workforce reskilling, blending traditional manufacturing knowledge with advanced digital competencies to optimize productivity and operational efficiency.

Implementation Costs: Brick-and-Mortar vs Virtual Setups

Implementation costs for brick-and-mortar factory floors typically involve substantial capital expenditures, including land acquisition, construction, machinery installation, and ongoing maintenance. Virtual factory setups reduce physical infrastructure expenses by leveraging digital twins, simulation software, and cloud computing, resulting in lower upfront and operational costs. However, virtual factories require significant investment in advanced IT infrastructure, cybersecurity, and skilled personnel to manage complex digital environments.

Flexibility and Scalability in Manufacturing Operations

Factory floors offer tangible control over machinery and workflow but often face limitations in flexibility due to fixed layouts and physical constraints. Virtual factories leverage digital twins and cloud-based simulations to enhance scalability, allowing quick adaptation to production changes and demand fluctuations without costly retooling. This digital approach enables manufacturers to optimize resource allocation and respond dynamically to market shifts, significantly improving operational efficiency.

Quality Control: Physical Inspection vs Digital Twin Analysis

Factory floor quality control relies heavily on physical inspection methods such as visual checks, measurement tools, and manual sampling to detect defects and ensure product standards. Virtual factory environments utilize digital twin analysis, leveraging real-time sensor data, advanced simulations, and AI-powered predictive models to identify potential quality issues before they occur. The integration of digital twins enables proactive quality management, reduces human error, and enhances traceability compared to traditional physical inspection approaches.

Future Trends: The Evolution of Smart Manufacturing

Future trends in smart manufacturing highlight the growing integration of virtual factories alongside traditional factory floors, leveraging digital twins and IoT to enhance real-time monitoring, predictive maintenance, and production agility. Virtual factories enable simulation-driven decision-making and remote management, significantly reducing downtime and operational costs while improving quality control. The convergence of AI, machine learning, and advanced robotics in both physical and virtual environments drives a transformative shift toward fully connected, adaptive manufacturing ecosystems.

Related Important Terms

Digital Twin

Digital Twin technology enables real-time simulation and monitoring on the factory floor, enhancing operational efficiency and predictive maintenance. Virtual Factory models replicate physical production environments digitally, allowing for process optimization and risk-free experimentation before implementation.

Cyber-Physical Systems

Cyber-Physical Systems integrate physical manufacturing processes with digital technologies, enabling real-time data exchange between Factory Floor operations and Virtual Factory simulations. This synergy enhances process optimization, predictive maintenance, and adaptive control, driving increased efficiency and reduced downtime in modern manufacturing environments.

Real-Time Data Streaming

Real-time data streaming in manufacturing enables seamless synchronization between factory floor operations and virtual factory models, enhancing predictive maintenance and process optimization. This continuous data flow ensures accurate digital twin simulations, facilitating faster decision-making and reducing production downtime.

Remote Monitoring Hubs

Remote Monitoring Hubs enable real-time oversight of both Factory Floor operations and Virtual Factory environments by integrating IoT sensors, AI analytics, and cloud computing for seamless data visualization and proactive issue resolution. These hubs enhance productivity and reduce downtime by providing centralized control and remote access to machine performance, quality metrics, and workflow status across distributed manufacturing sites.

Augmented Reality Workstations

Augmented reality workstations transform both factory floor and virtual factory environments by overlaying real-time data and interactive 3D models directly onto production spaces, enhancing operator precision and reducing downtime. Integrating AR technology streamlines assembly processes and quality control, driving efficiency and innovation in smart manufacturing ecosystems.

Edge Computing Nodes

Edge computing nodes on the factory floor enable real-time data processing and low-latency decision-making by collecting and analyzing machine data locally, reducing reliance on cloud connectivity. In contrast, virtual factories leverage centralized cloud computing with simulated environments but often face latency issues, making edge nodes critical for enhancing operational efficiency and responsiveness in smart manufacturing.

Virtual Commissioning

Virtual commissioning leverages digital twins and simulation software to test and validate manufacturing processes before physical implementation, reducing downtime and costs on the factory floor. By integrating real-time data and advanced analytics, virtual factories enable faster troubleshooting and optimization, enhancing production efficiency and flexibility in dynamic manufacturing environments.

Digital Thread

The Factory Floor integrates physical machinery with real-time data collection, enabling immediate process adjustments and operational efficiency. The Virtual Factory leverages a digital thread, connecting design, production, and quality data across the product lifecycle to optimize manufacturing workflows and predictive maintenance.

Cloud-Based MES (Manufacturing Execution System)

Cloud-based MES platforms enable real-time data collection and analytics on the factory floor, enhancing production efficiency and reducing downtime through seamless integration with IoT devices. Virtual factories leverage cloud MES to simulate manufacturing processes, optimize workflows, and facilitate remote monitoring, driving digital transformation in smart manufacturing.

Smart Factory Analytics

Smart factory analytics leverage IoT sensors, real-time data, and AI algorithms to optimize production efficiency, asset utilization, and predictive maintenance on the factory floor. Virtual factories utilize digital twins and simulation models to analyze workflows, forecast bottlenecks, and enhance decision-making without disrupting physical operations.

Factory Floor vs Virtual Factory Infographic

industrydif.com

industrydif.com