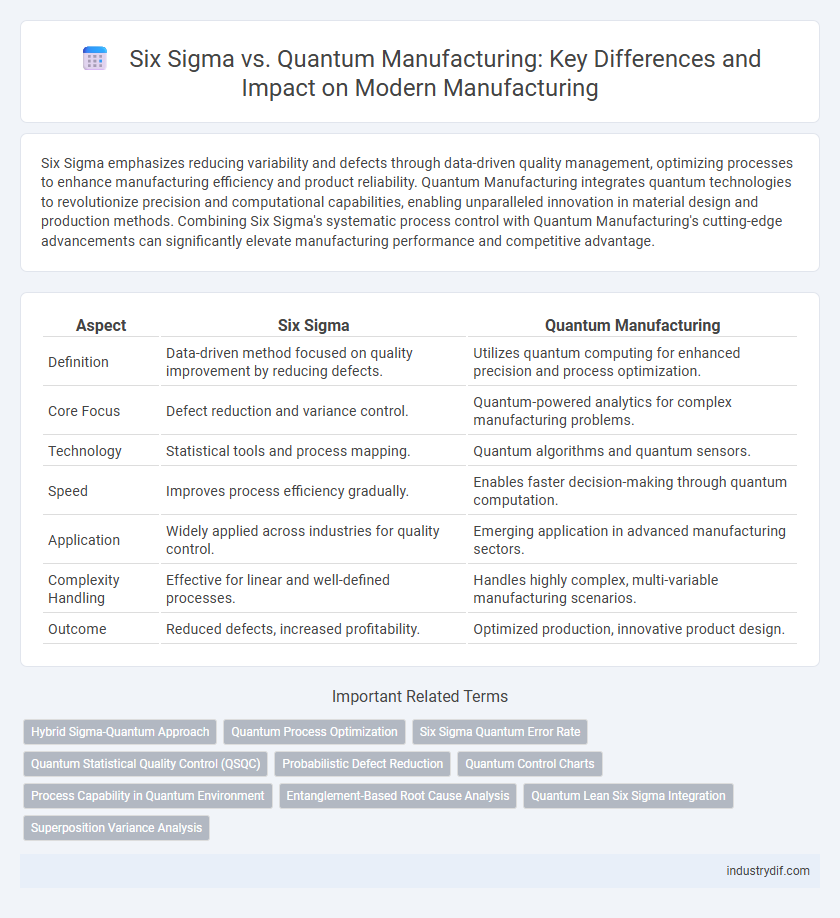

Six Sigma emphasizes reducing variability and defects through data-driven quality management, optimizing processes to enhance manufacturing efficiency and product reliability. Quantum Manufacturing integrates quantum technologies to revolutionize precision and computational capabilities, enabling unparalleled innovation in material design and production methods. Combining Six Sigma's systematic process control with Quantum Manufacturing's cutting-edge advancements can significantly elevate manufacturing performance and competitive advantage.

Table of Comparison

| Aspect | Six Sigma | Quantum Manufacturing |

|---|---|---|

| Definition | Data-driven method focused on quality improvement by reducing defects. | Utilizes quantum computing for enhanced precision and process optimization. |

| Core Focus | Defect reduction and variance control. | Quantum-powered analytics for complex manufacturing problems. |

| Technology | Statistical tools and process mapping. | Quantum algorithms and quantum sensors. |

| Speed | Improves process efficiency gradually. | Enables faster decision-making through quantum computation. |

| Application | Widely applied across industries for quality control. | Emerging application in advanced manufacturing sectors. |

| Complexity Handling | Effective for linear and well-defined processes. | Handles highly complex, multi-variable manufacturing scenarios. |

| Outcome | Reduced defects, increased profitability. | Optimized production, innovative product design. |

Introduction to Six Sigma and Quantum Manufacturing

Six Sigma is a data-driven methodology aimed at reducing defects and improving quality by identifying and eliminating variations in manufacturing processes, achieving near-perfect production efficiency with a goal of 3.4 defects per million opportunities. Quantum Manufacturing leverages quantum technologies such as quantum sensors and quantum computing to revolutionize production precision, enabling unprecedented control at the atomic and molecular levels for enhanced material properties and process optimization. While Six Sigma emphasizes statistical analysis and process improvement, Quantum Manufacturing introduces a paradigm shift by integrating quantum mechanics to fundamentally transform manufacturing capabilities.

Core Principles of Six Sigma

Six Sigma centers on reducing process variation and eliminating defects through data-driven methodologies such as DMAIC (Define, Measure, Analyze, Improve, Control). It emphasizes customer-centric quality improvements by systematically identifying and addressing root causes of errors to achieve near-perfect product consistency. Quantum Manufacturing, in contrast, integrates advanced quantum computing and real-time analytics to optimize production processes beyond traditional Six Sigma approaches.

Fundamentals of Quantum Manufacturing

Quantum manufacturing leverages principles of quantum mechanics to manipulate materials at atomic and subatomic levels, enabling unprecedented precision and efficiency. Unlike Six Sigma's focus on reducing defects through process improvements, quantum manufacturing emphasizes quantum state control, entanglement, and superposition to enhance fabrication processes. Fundamental quantum manufacturing techniques include quantum lithography, quantum sensing, and quantum computing integration, paving the way for revolutionary advancements in nanoscale production.

Key Differences between Six Sigma and Quantum Manufacturing

Six Sigma focuses on reducing process variation and improving quality through statistical analysis and structured methodologies like DMAIC, while Quantum Manufacturing leverages quantum technologies to revolutionize production at the atomic and molecular level, enabling unprecedented precision and efficiency. Six Sigma emphasizes incremental improvements and defect reduction in traditional manufacturing processes, whereas Quantum Manufacturing introduces novel capabilities by integrating quantum computing, quantum sensors, and quantum materials to transform design, control, and optimization. The key distinctions lie in Six Sigma's data-driven quality control framework versus Quantum Manufacturing's foundational reliance on quantum physics principles to achieve breakthrough advancements.

Application Areas in Modern Manufacturing

Six Sigma is predominantly applied in quality control, process optimization, and reducing variability within manufacturing workflows, particularly in automotive, electronics, and pharmaceutical industries. Quantum Manufacturing leverages quantum computing and sensing technologies to enhance material design, precision measurement, and real-time process monitoring, with strong implications for semiconductor fabrication and advanced materials production. Integrating Six Sigma methodologies with Quantum Manufacturing innovations accelerates defect detection, predictive maintenance, and efficiency improvements across modern manufacturing sectors.

Impact on Process Efficiency and Quality Control

Six Sigma utilizes data-driven methodologies and statistical analysis to reduce process variability, significantly enhancing quality control and operational efficiency in manufacturing. Quantum Manufacturing leverages quantum computing and advanced algorithms to optimize complex production networks, enabling faster problem-solving and more precise defect detection. Both approaches improve process efficiency and quality control, but Quantum Manufacturing holds potential for exponential advancements through superior computational power and real-time adaptive capabilities.

Technology Integration: Traditional vs Quantum Approaches

Six Sigma relies on statistical methods and process optimization tools to reduce variability and defects in manufacturing, integrating traditional data analytics and control systems. Quantum manufacturing leverages quantum computing and quantum sensors to analyze complex datasets and optimize processes at a molecular or atomic level, enabling unprecedented precision and predictive capabilities. The integration of quantum technologies offers transformative advancements over conventional Six Sigma techniques by accelerating problem-solving and enhancing real-time process monitoring.

Data Analytics in Six Sigma and Quantum Manufacturing

Six Sigma leverages data analytics through statistical tools and process control charts to identify and eliminate defects, improving manufacturing efficiency and product quality. Quantum Manufacturing integrates advanced quantum computing algorithms and machine learning models to analyze vast datasets, enabling real-time optimization and predictive maintenance beyond classical analytical limits. The integration of data analytics in Quantum Manufacturing offers exponential processing power for complex problem-solving, surpassing the capabilities of traditional Six Sigma methodologies.

Challenges in Implementation

Six Sigma implementation often faces challenges such as resistance to change, high training costs, and difficulty in sustaining long-term process improvements. Quantum manufacturing introduces complexities including the need for specialized quantum expertise, integration with classical systems, and overcoming scalability limitations in quantum technologies. Both approaches require significant cultural shifts and resource investments to achieve operational excellence.

Future Trends and Industry Outlook

Six Sigma continues to enhance manufacturing efficiency by minimizing defects and optimizing processes, while Quantum Manufacturing leverages quantum computing to revolutionize materials design and supply chain management. Future trends indicate a fusion of these methodologies, where data-driven Six Sigma principles integrate with quantum algorithms to accelerate innovation and precision. Industry outlook predicts widespread adoption of Quantum Manufacturing technologies, transforming production capabilities and setting new standards for quality and speed.

Related Important Terms

Hybrid Sigma-Quantum Approach

The Hybrid Sigma-Quantum Approach combines Six Sigma's data-driven quality control with Quantum Manufacturing's cutting-edge quantum computing and automation capabilities to optimize production efficiency and reduce defects in complex manufacturing processes. This integration enables real-time process optimization and predictive analytics, driving unprecedented precision and cost-effectiveness in advanced manufacturing environments.

Quantum Process Optimization

Quantum Process Optimization leverages quantum computing to analyze complex manufacturing data sets exponentially faster than Six Sigma's statistical methods, enabling real-time adjustments and predictive maintenance for enhanced production efficiency. While Six Sigma focuses on reducing defects through process variation control, Quantum Manufacturing optimizes entire workflows by simulating multiple variables simultaneously, driving unprecedented precision and innovation in industrial operations.

Six Sigma Quantum Error Rate

Six Sigma targets a defect rate of 3.4 defects per million opportunities, ensuring near-perfect process quality, whereas Quantum Manufacturing leverages quantum technologies to push error rates even lower by exploiting quantum error correction methods. The Six Sigma Quantum Error Rate signifies the integration of quantum principles into Six Sigma frameworks, aiming to achieve unprecedented precision in defect reduction and process optimization.

Quantum Statistical Quality Control (QSQC)

Quantum Statistical Quality Control (QSQC) leverages quantum computing principles to analyze manufacturing data sets with unprecedented speed and accuracy, surpassing traditional Six Sigma methods that rely on classical statistical tools. QSQC enables real-time defect detection and process optimization by utilizing quantum algorithms, resulting in higher precision and reduced variability in manufacturing outputs.

Probabilistic Defect Reduction

Six Sigma employs statistical methods to reduce defects with a target of 3.4 defects per million opportunities, emphasizing process control and consistency. Quantum Manufacturing leverages quantum computing algorithms to model complex probabilistic outcomes, potentially enabling more precise defect prediction and reduction beyond classical Six Sigma capabilities.

Quantum Control Charts

Quantum Control Charts in Quantum Manufacturing leverage quantum computing's probabilistic data processing to enhance defect detection and process variation analysis, surpassing traditional Six Sigma control charts in accuracy and real-time responsiveness. This innovation allows manufacturers to optimize quality control by integrating quantum algorithms that dynamically adjust parameters, reducing error rates and accelerating production cycles.

Process Capability in Quantum Environment

Quantum manufacturing leverages quantum computing to enhance process capability by enabling unprecedented precision and real-time data analysis, surpassing traditional Six Sigma methodologies that primarily focus on statistical process control and defect reduction. This quantum-enabled process capability facilitates adaptive optimization and predictive maintenance, driving higher efficiency and consistency in complex manufacturing environments.

Entanglement-Based Root Cause Analysis

Six Sigma relies on statistical methods to reduce defects and variability, whereas Quantum Manufacturing employs entanglement-based root cause analysis to identify interconnected process anomalies at the quantum level. This advanced approach enables precise detection of causality patterns beyond classical probabilistic models, significantly enhancing defect prevention and process optimization.

Quantum Lean Six Sigma Integration

Quantum Lean Six Sigma Integration combines traditional Six Sigma's data-driven quality improvement with quantum computing's enhanced processing power, enabling faster and more precise defect detection in manufacturing processes. This fusion accelerates complex analytics and optimizes resource allocation, driving higher efficiency and reduced production costs in modern manufacturing environments.

Superposition Variance Analysis

Superposition Variance Analysis in Quantum Manufacturing leverages quantum superposition principles to analyze process variations at multiple states simultaneously, offering significantly higher precision compared to traditional Six Sigma methods that rely on classical statistical tools. This quantum approach enables manufacturers to detect and control complex variances that Six Sigma's classical variance analysis may overlook, leading to enhanced product quality and reduced defects.

Six Sigma vs Quantum Manufacturing Infographic

industrydif.com

industrydif.com