Kaizen emphasizes continuous incremental improvements by engaging all employees in identifying and solving problems, fostering a culture of ongoing enhancement in manufacturing processes. Holonic Manufacturing systems organize production into autonomous, cooperative units called holons that can dynamically adapt to changes and optimize overall system performance. Comparing both, Kaizen centers on gradual process refinement through human intervention, while Holonic Manufacturing leverages decentralized, intelligent manufacturing entities for real-time adaptability and efficiency.

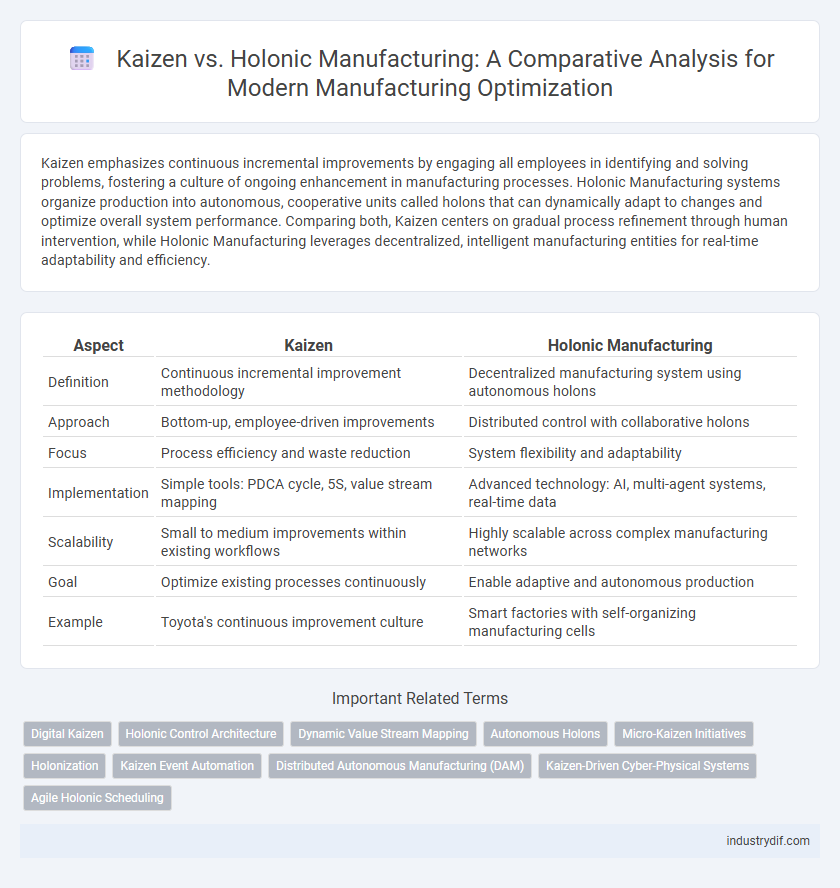

Table of Comparison

| Aspect | Kaizen | Holonic Manufacturing |

|---|---|---|

| Definition | Continuous incremental improvement methodology | Decentralized manufacturing system using autonomous holons |

| Approach | Bottom-up, employee-driven improvements | Distributed control with collaborative holons |

| Focus | Process efficiency and waste reduction | System flexibility and adaptability |

| Implementation | Simple tools: PDCA cycle, 5S, value stream mapping | Advanced technology: AI, multi-agent systems, real-time data |

| Scalability | Small to medium improvements within existing workflows | Highly scalable across complex manufacturing networks |

| Goal | Optimize existing processes continuously | Enable adaptive and autonomous production |

| Example | Toyota's continuous improvement culture | Smart factories with self-organizing manufacturing cells |

Introduction to Kaizen and Holonic Manufacturing

Kaizen is a continuous improvement methodology originating from Japan that emphasizes incremental changes to enhance productivity, quality, and efficiency in manufacturing processes. Holonic Manufacturing integrates autonomous, cooperative units called holons that can self-regulate and adapt within a complex production system to improve flexibility and responsiveness. Both approaches aim to optimize manufacturing operations but differ in their focus, with Kaizen targeting gradual process improvements and Holonic Manufacturing emphasizing decentralized control and dynamic adaptability.

Core Principles of Kaizen

Kaizen centers on continuous, incremental improvements driven by employee involvement and standardized processes to enhance efficiency and reduce waste on the manufacturing floor. Its core principles emphasize teamwork, discipline, and systematic problem-solving to foster a culture of ongoing productivity gains. In contrast to Holonic Manufacturing's flexible, autonomous system structure, Kaizen prioritizes steady, small-scale enhancements rooted in collective workforce engagement.

Fundamentals of Holonic Manufacturing

Holonic Manufacturing integrates autonomous, cooperative units called holons that operate both independently and collaboratively within a distributed control system, enhancing adaptability and scalability. Unlike Kaizen's continuous incremental improvements, Holonic Manufacturing emphasizes decentralized decision-making and real-time responsiveness to dynamic production environments. This fundamental structure supports complex workflows and promotes resilience in manufacturing systems by combining the advantages of both hierarchical and heterarchical control.

Historical Evolution of Manufacturing Paradigms

Kaizen, originating in post-World War II Japan, emphasizes continuous incremental improvements focused on employee involvement and waste reduction. Holonic Manufacturing Systems (HMS), developed in the 1990s, represent a shift toward decentralized, autonomous production units called holons that balance flexibility and control in complex manufacturing environments. The historical evolution from Kaizen to Holonic Manufacturing reflects a progression from human-centric process optimization to integrated, adaptive cyber-physical systems designed for Industry 4.0 advancements.

Key Differences Between Kaizen and Holonic Manufacturing

Kaizen emphasizes continuous incremental improvements driven by employee involvement and small-scale changes, fostering a culture of quality enhancement in manufacturing processes. Holonic manufacturing integrates autonomous, cooperative units called holons that combine to form flexible, adaptive production systems for improved scalability and responsiveness. The key difference lies in Kaizen's focus on human-centered process optimization versus Holonic manufacturing's system-oriented modular architecture enabling dynamic reconfiguration.

Integration of Kaizen in Modern Manufacturing

Kaizen promotes continuous, incremental improvements that enhance operational efficiency and minimize waste in manufacturing processes. Holonic manufacturing integrates autonomous, cooperative units called holons, enabling flexibility and adaptability in complex production systems. Incorporating Kaizen into holonic manufacturing frameworks optimizes real-time decision-making and fosters a culture of ongoing innovation and quality enhancement.

Applications of Holonic Manufacturing Systems

Holonic Manufacturing Systems (HMS) are extensively applied in flexible production environments, enabling real-time adaptation to changing customer demands and production schedules. They facilitate decentralized control, integrating autonomous holons that communicate and cooperate to optimize workflow, increase efficiency, and reduce downtime. Competently implemented HMS improve scalability and responsiveness in complex manufacturing processes, surpassing traditional continuous improvement approaches like Kaizen in dynamic settings.

Comparative Benefits and Challenges

Kaizen emphasizes continuous incremental improvements driven by employee involvement, enhancing efficiency and reducing waste but may face resistance due to cultural shifts and time-intensive processes. Holonic Manufacturing integrates autonomous, cooperative units called holons, offering flexibility, scalability, and real-time adaptability while presenting challenges in system complexity and integration costs. Both methodologies aim to optimize production, with Kaizen excelling in gradual process refinement and Holonic Manufacturing excelling in dynamic, decentralized control.

Case Studies: Kaizen vs Holonic Manufacturing

Case studies reveal Kaizen's strength in continuous incremental improvements, boosting productivity and reducing waste through employee-driven processes in manufacturing plants such as Toyota's assembly lines. Holonic Manufacturing showcases adaptability and resilience by employing autonomous, self-organizing production units that enable flexible responses to dynamic market demands, demonstrated by European aerospace manufacturing projects like Holonic Assembly Systems. Comparative analysis highlights Kaizen's effectiveness in structured environments with stable workflows, whereas Holonic systems excel in complex, rapidly changing production scenarios requiring decentralized control.

Future Trends in Manufacturing Methodologies

Kaizen emphasizes continuous incremental improvements driven by employee involvement, optimizing existing processes for efficiency and quality. Holonic Manufacturing integrates autonomous, self-organizing units called holons, enabling flexible, adaptive production systems that respond rapidly to changing demands. Future trends point towards hybrid methodologies combining Kaizen's human-centric improvements with Holonic systems' decentralized control to enhance manufacturing agility and resilience.

Related Important Terms

Digital Kaizen

Digital Kaizen leverages real-time data analytics and IoT integration to continuously improve manufacturing processes by identifying inefficiencies and enabling rapid decision-making. Holonic Manufacturing structures production into autonomous, cooperative units called holons, enhancing flexibility and scalability, but Digital Kaizen specifically drives incremental innovation through sustained digital feedback loops.

Holonic Control Architecture

Holonic Control Architecture in manufacturing integrates autonomous, cooperative holons that dynamically coordinate to optimize production processes, enhancing flexibility and scalability compared to traditional Kaizen continuous improvement methods. This architecture supports real-time decision-making and decentralized control, leading to increased system robustness and adaptability in complex manufacturing environments.

Dynamic Value Stream Mapping

Kaizen emphasizes continuous incremental improvements within existing processes, while Holonic Manufacturing leverages autonomous, cooperative units for flexible production systems. Dynamic Value Stream Mapping integrates real-time data to optimize process flows, enabling adaptive decision-making that enhances both Kaizen-driven enhancements and Holonic Manufacturing's modular efficiency.

Autonomous Holons

Kaizen emphasizes continuous incremental improvements driven by employee involvement, whereas Holonic Manufacturing utilizes autonomous holons--self-organizing, intelligent units capable of independent decision-making and adaptability within complex production systems. Autonomous holons enhance manufacturing flexibility and resilience by dynamically coordinating tasks and resources without centralized control, outperforming traditional improvement methods in responding to real-time operational changes.

Micro-Kaizen Initiatives

Micro-Kaizen initiatives emphasize continuous, incremental improvements at the operational level, fostering employee-driven enhancements to reduce waste and optimize efficiency. In contrast, Holonic Manufacturing integrates modular, autonomous units, combining flexibility and adaptability but relying less on grassroots, small-scale changes typical of Micro-Kaizen practices.

Holonization

Holonization in manufacturing integrates autonomous holons that collaboratively manage production processes, enhancing flexibility and scalability compared to traditional Kaizen continuous improvement methods. This approach enables dynamic adaptation to changing demands by decentralizing control, optimizing resource allocation, and promoting real-time decision-making on the shop floor.

Kaizen Event Automation

Kaizen event automation streamlines continuous improvement processes in manufacturing by integrating real-time data analytics and collaborative digital tools to identify inefficiencies and implement incremental changes swiftly. Unlike holonic manufacturing, which emphasizes decentralized control and autonomous production units, Kaizen automation focuses on enhancing human-driven problem-solving cycles to boost productivity and quality systematically.

Distributed Autonomous Manufacturing (DAM)

Kaizen emphasizes continuous incremental improvements driven by employee involvement, while Holonic Manufacturing utilizes decentralized, autonomous units or 'holons' that collaboratively optimize production processes. Distributed Autonomous Manufacturing (DAM) leverages these holons to enable flexible, self-organizing systems that enhance scalability, responsiveness, and real-time decision-making across complex manufacturing networks.

Kaizen-Driven Cyber-Physical Systems

Kaizen-driven cyber-physical systems integrate continuous improvement principles into manufacturing processes by enabling real-time data analytics and adaptive control mechanisms that optimize production efficiency and quality. These systems contrast with holonic manufacturing by emphasizing incremental employee-led enhancements and lean management within networked physical and digital components.

Agile Holonic Scheduling

Agile Holonic Scheduling in manufacturing leverages decentralized decision-making and autonomous production units to optimize workflow efficiency and adaptability, contrasting with Kaizen's continuous but incremental improvement philosophy. This approach enables real-time responsiveness and dynamic resource allocation, significantly enhancing operational agility in complex manufacturing environments.

Kaizen vs Holonic Manufacturing Infographic

industrydif.com

industrydif.com