Quality control ensures products meet specified standards through systematic inspection and testing, preventing defects and maintaining consistency in manufacturing processes. Predictive maintenance uses data analytics and sensor technology to forecast equipment failures before they occur, reducing downtime and optimizing machine performance. Combining both strategies enhances operational efficiency by delivering high-quality products while minimizing unexpected disruptions.

Table of Comparison

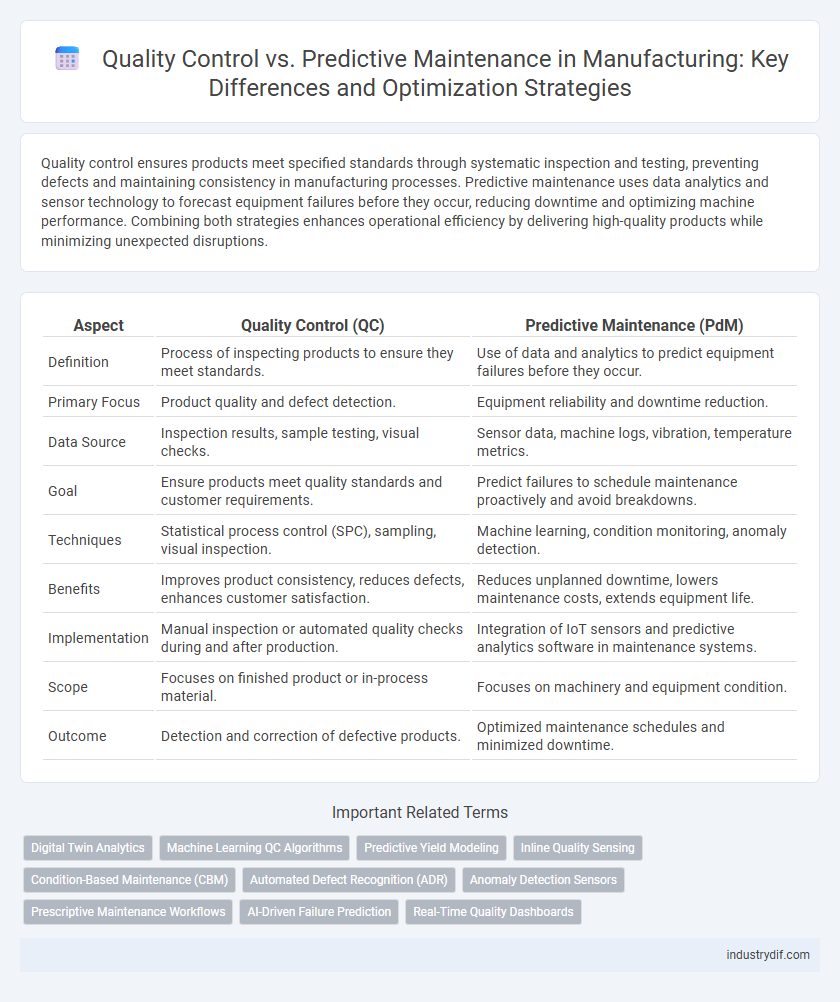

| Aspect | Quality Control (QC) | Predictive Maintenance (PdM) |

|---|---|---|

| Definition | Process of inspecting products to ensure they meet standards. | Use of data and analytics to predict equipment failures before they occur. |

| Primary Focus | Product quality and defect detection. | Equipment reliability and downtime reduction. |

| Data Source | Inspection results, sample testing, visual checks. | Sensor data, machine logs, vibration, temperature metrics. |

| Goal | Ensure products meet quality standards and customer requirements. | Predict failures to schedule maintenance proactively and avoid breakdowns. |

| Techniques | Statistical process control (SPC), sampling, visual inspection. | Machine learning, condition monitoring, anomaly detection. |

| Benefits | Improves product consistency, reduces defects, enhances customer satisfaction. | Reduces unplanned downtime, lowers maintenance costs, extends equipment life. |

| Implementation | Manual inspection or automated quality checks during and after production. | Integration of IoT sensors and predictive analytics software in maintenance systems. |

| Scope | Focuses on finished product or in-process material. | Focuses on machinery and equipment condition. |

| Outcome | Detection and correction of defective products. | Optimized maintenance schedules and minimized downtime. |

Understanding Quality Control in Modern Manufacturing

Quality control in modern manufacturing involves systematic inspection and testing to ensure products meet defined specifications and industry standards, minimizing defects and maintaining customer satisfaction. Advanced techniques such as statistical process control (SPC) and automated optical inspection (AOI) enhance the precision and efficiency of quality assessments. Integration of real-time data analytics enables manufacturers to promptly identify deviations, reduce waste, and improve overall production quality.

What is Predictive Maintenance? An Overview

Predictive maintenance uses real-time data from sensors and advanced analytics to forecast equipment failures before they occur, minimizing unplanned downtime in manufacturing. This approach leverages machine learning algorithms to identify patterns and anomalies, enabling timely interventions and optimized maintenance schedules. By contrast to traditional quality control, predictive maintenance prioritizes proactive asset management to enhance operational efficiency and reduce maintenance costs.

Key Differences Between Quality Control and Predictive Maintenance

Quality control in manufacturing focuses on inspecting products to ensure they meet defined standards, emphasizing defect detection and process consistency. Predictive maintenance utilizes data analytics and sensor monitoring to forecast equipment failures, aiming to prevent downtime and optimize machinery lifespan. The key difference lies in quality control targeting output quality, whereas predictive maintenance targets the health and reliability of manufacturing assets.

Goals and Objectives: QC vs Predictive Maintenance

Quality Control in manufacturing aims to ensure products meet predefined standards by identifying defects and minimizing variability during production processes. Predictive Maintenance focuses on anticipating equipment failures through data analysis and sensor monitoring to reduce downtime and maintenance costs. Both strategies enhance operational efficiency but target different stages: Quality Control safeguards product integrity while Predictive Maintenance preserves machinery reliability.

Tools and Technologies: From Inspection to IoT Sensors

Quality control relies on advanced inspection tools such as coordinate measuring machines (CMM) and optical scanners to detect defects and ensure compliance with manufacturing standards. Predictive maintenance leverages IoT sensors, vibration analyzers, and machine learning algorithms to monitor equipment health and predict failures before they occur. Integrating these technologies enables manufacturers to optimize production efficiency, reduce downtime, and maintain product quality consistently.

Impact on Production Efficiency and Downtime

Quality control ensures consistent product standards by detecting defects early, minimizing rework and scrap, directly improving production efficiency. Predictive maintenance uses sensor data and analytics to forecast equipment failures, reducing unexpected downtime and enabling scheduled repairs. Both strategies complement each other by balancing defect prevention with machinery reliability, optimizing overall operational performance in manufacturing environments.

Data Collection and Analysis in QC and Predictive Maintenance

Quality Control relies heavily on precise data collection from production processes, utilizing statistical methods to detect and reduce defects during manufacturing. Predictive Maintenance uses sensor data and machine learning algorithms to analyze equipment conditions, predicting failures before they occur and minimizing downtime. Both approaches depend on real-time data acquisition and advanced analytics, but Quality Control focuses on product integrity, while Predictive Maintenance targets equipment reliability.

Cost Implications: Prevention vs Correction

Quality control reduces overall manufacturing costs by preventing defects before they occur, minimizing waste and rework expenses. Predictive maintenance lowers downtime costs by forecasting equipment failures and scheduling timely repairs, avoiding expensive breakdowns. Investing in prevention through quality control and predictive maintenance leads to significant cost savings compared to corrective actions taken after failures or defects emerge.

Integration Challenges in Digital Manufacturing

Integrating quality control and predictive maintenance systems in digital manufacturing presents challenges such as data incompatibility and inconsistent communication protocols between diverse equipment and software platforms. The synchronization of real-time quality data with predictive algorithms requires robust data validation processes to prevent inaccurate maintenance decisions. Overcoming these integration hurdles is critical for achieving seamless operations and maximizing efficiency in smart factories.

Future Trends: Harmonizing Quality Control and Predictive Maintenance

Future trends in manufacturing emphasize the integration of Quality Control and Predictive Maintenance through advanced IoT sensors and AI-driven analytics, enabling real-time defect detection and equipment health monitoring. Machine learning algorithms optimize production efficiency by predicting equipment failures while simultaneously ensuring product quality standards are met. This harmonization reduces downtime, lowers operational costs, and enhances overall manufacturing reliability and productivity.

Related Important Terms

Digital Twin Analytics

Digital Twin Analytics enables manufacturers to simulate equipment behavior under various conditions, enhancing Predictive Maintenance by forecasting failures before they occur and reducing downtime. While Quality Control ensures product standards through inspection and testing, Digital Twin Analytics integrates real-time sensor data to optimize maintenance schedules and improve overall operational efficiency.

Machine Learning QC Algorithms

Machine learning QC algorithms analyze real-time production data to identify defects and deviations, enhancing quality control accuracy and reducing manual inspection costs. Predictive maintenance uses similar data-driven models to forecast equipment failures, minimizing downtime, but quality control focuses specifically on ensuring product standards and consistency.

Predictive Yield Modeling

Predictive yield modeling enhances quality control by using real-time data analytics and machine learning algorithms to forecast production outcomes, reducing defects and optimizing resource utilization. Integrating predictive maintenance within this framework minimizes equipment downtime and ensures consistent manufacturing performance, driving higher yield accuracy and operational efficiency.

Inline Quality Sensing

Inline quality sensing integrates real-time data capture with automated analysis, enabling immediate detection of defects during manufacturing processes to enhance product consistency and reduce waste. This contrasts with predictive maintenance, which focuses on forecasting equipment failures to prevent downtime, emphasizing machine health over continuous quality monitoring.

Condition-Based Maintenance (CBM)

Quality Control ensures product standards through rigorous inspection and testing during manufacturing, while Predictive Maintenance, driven by Condition-Based Maintenance (CBM), utilizes real-time sensor data and analytics to monitor equipment health, preventing unexpected failures and reducing downtime. CBM focuses on actual machine conditions rather than scheduled intervals, optimizing maintenance resources and enhancing overall production efficiency.

Automated Defect Recognition (ADR)

Automated Defect Recognition (ADR) enhances Quality Control by using AI-driven image analysis to identify manufacturing defects in real-time, ensuring consistent product standards. Predictive Maintenance leverages sensor data and machine learning to foresee equipment failures, minimizing downtime but does not directly detect product defects like ADR does.

Anomaly Detection Sensors

Anomaly detection sensors in manufacturing enhance quality control by identifying defects and deviations in real-time, ensuring product consistency and reducing waste. In predictive maintenance, these sensors monitor equipment conditions to detect unusual patterns early, preventing breakdowns and optimizing operational efficiency.

Prescriptive Maintenance Workflows

Quality control ensures product consistency through systematic inspection protocols, while predictive maintenance uses real-time data analytics to forecast equipment failures; prescriptive maintenance workflows integrate these approaches by providing actionable recommendations that optimize both product quality and machine uptime. Implementing AI-driven prescriptive analytics enhances decision-making, reducing downtime and defects simultaneously in manufacturing environments.

AI-Driven Failure Prediction

AI-driven failure prediction enhances quality control by analyzing real-time manufacturing data to detect defects before they occur, reducing downtime and improving product consistency. Predictive maintenance leverages machine learning algorithms to forecast equipment failures, optimizing maintenance schedules and minimizing unexpected disruptions.

Real-Time Quality Dashboards

Real-time quality dashboards integrate data from quality control and predictive maintenance systems to provide instant insights into production defects and machine health, enabling faster decision-making and minimizing downtime. Leveraging IoT sensors and AI analytics, these dashboards enhance manufacturing efficiency by continuously monitoring product quality parameters alongside equipment performance metrics.

Quality Control vs Predictive Maintenance Infographic

industrydif.com

industrydif.com