Traditional machining involves subtractive processes that precisely shape materials by removing excess parts, ideal for producing high-strength components with tight tolerances. Additive manufacturing builds parts layer by layer, enabling complex geometries and reducing material waste while accelerating prototyping and customization. Comparing both methods reveals that traditional machining excels in durability and finish, whereas additive manufacturing offers flexibility and rapid design iterations.

Table of Comparison

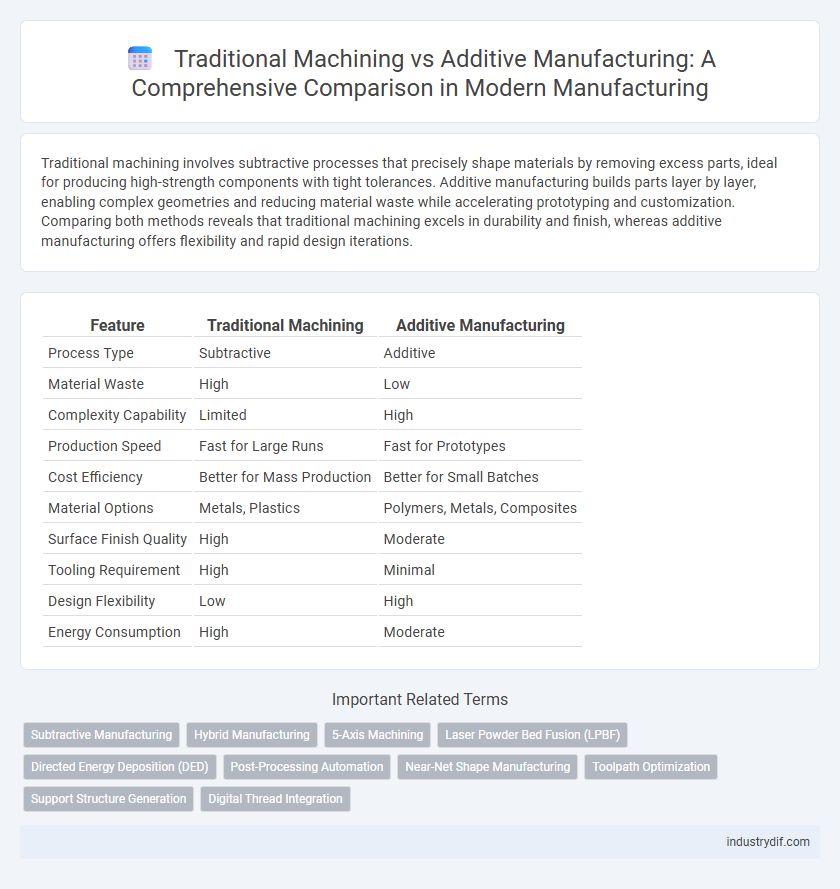

| Feature | Traditional Machining | Additive Manufacturing |

|---|---|---|

| Process Type | Subtractive | Additive |

| Material Waste | High | Low |

| Complexity Capability | Limited | High |

| Production Speed | Fast for Large Runs | Fast for Prototypes |

| Cost Efficiency | Better for Mass Production | Better for Small Batches |

| Material Options | Metals, Plastics | Polymers, Metals, Composites |

| Surface Finish Quality | High | Moderate |

| Tooling Requirement | High | Minimal |

| Design Flexibility | Low | High |

| Energy Consumption | High | Moderate |

Introduction to Traditional Machining and Additive Manufacturing

Traditional machining involves subtractive processes such as turning, milling, and drilling, where material is removed from a solid block to create precise components. Additive manufacturing, also known as 3D printing, builds parts layer-by-layer using materials like plastics, metals, or composites, enabling complex geometries unachievable by conventional methods. Both technologies serve critical roles in manufacturing, with traditional machining excelling in high-strength, tight-tolerance parts and additive manufacturing enabling rapid prototyping and customized production.

Core Principles of Subtractive vs Additive Processes

Traditional machining relies on subtractive processes, removing material from a solid block through cutting, drilling, or milling to achieve the desired shape, emphasizing precision and surface finish. Additive manufacturing builds components layer by layer from digital models using materials like polymers, metals, or composites, enabling complex geometries and customization. Subtractive methods prioritize material removal and machining time, whereas additive processes focus on material addition and design flexibility, impacting production speed, waste, and cost.

Material Considerations in Manufacturing Methods

Traditional machining utilizes subtractive processes that often generate significant material waste and limit the use of complex geometries, favoring metals like aluminum, steel, and titanium known for their machinability and strength. Additive manufacturing, or 3D printing, builds parts layer-by-layer, enabling complex designs and efficient material usage with a wider range of materials including polymers, composites, and metal powders tailored for specific mechanical properties. Material selection in additive manufacturing impacts factors such as build time, surface finish, and structural integrity, offering advantages in customization and rapid prototyping over traditional machining's precision and repeatability.

Precision and Tolerances: Comparing Capabilities

Traditional machining offers high precision and tight tolerances, typically achieving accuracy within microns due to subtractive processes like milling and turning that remove material. Additive manufacturing provides competitive precision, especially with technologies such as selective laser sintering and stereolithography, but may face limitations in achieving ultra-tight tolerances compared to CNC machining. Tolerance capabilities vary widely by AM method, impacting applications that demand exact fit and finish in aerospace, automotive, and medical device manufacturing.

Design Flexibility and Geometric Complexities

Traditional machining involves subtractive processes that constrain design flexibility due to limitations in tool access and material removal paths, often making complex geometries costly or impossible to achieve. Additive manufacturing enables unparalleled design freedom by building components layer-by-layer, allowing intricate internal structures and organic shapes with minimal material waste. This capability supports optimized lightweight designs and customized parts that are challenging or unfeasible with conventional machining techniques.

Production Speed and Turnaround Times

Traditional machining often involves longer production speeds and extended turnaround times due to extensive setup, tooling, and material removal processes. Additive manufacturing accelerates production by building parts layer-by-layer directly from digital files, significantly reducing lead times and enabling rapid prototyping. This technology optimizes manufacturing workflows by minimizing delays between design and final product delivery.

Cost Analysis: Upfront and Operational Expenses

Traditional machining demands higher upfront costs due to expensive tooling, molds, and setup times, while additive manufacturing reduces initial expenses by eliminating the need for specialized tools. Operational expenses in traditional machining include material waste and longer production cycles, whereas additive manufacturing offers cost-efficiency through minimal waste and faster prototyping. Over the long term, additive manufacturing can lower total production costs by enabling design flexibility and reducing inventory requirements.

Scalability and Batch Production Efficiency

Traditional machining excels in batch production efficiency by utilizing established tooling and process optimizations that reduce cycle times for large-scale manufacturing. Additive manufacturing offers superior scalability for low to medium volumes, enabling rapid design changes without the need for costly retooling or setup adjustments. While traditional methods benefit from economies of scale in mass production, additive processes provide flexible scalability that supports customized production and short runs with minimal lead time.

Environmental Impact and Material Waste

Traditional machining generates significant material waste due to subtractive processes, producing excess chips and scraps that require disposal or recycling, contributing to environmental degradation. Additive manufacturing significantly reduces waste by building parts layer-by-layer, using only the necessary material and enabling lightweight, resource-efficient designs that lower carbon emissions. Furthermore, additive techniques often consume less energy overall, making them a more sustainable option in terms of both material efficiency and environmental impact.

Future Trends in Hybrid Manufacturing Approaches

Future trends in hybrid manufacturing integrate traditional machining with additive manufacturing to enhance precision and reduce production time. Combining CNC milling and 3D printing enables complex geometries and customized parts with improved material efficiency. Advances in machine learning and real-time monitoring systems drive the evolution of adaptive hybrid manufacturing workflows, optimizing performance and sustainability in industrial production.

Related Important Terms

Subtractive Manufacturing

Subtractive manufacturing, a core process in traditional machining, involves removing material from a solid block using tools like lathes, mills, and drills to achieve precise dimensions and surface finishes. This method excels in producing high-strength metal components with tight tolerances, making it ideal for aerospace and automotive industries where durability and accuracy are critical.

Hybrid Manufacturing

Hybrid manufacturing combines traditional machining's precision and surface finish with additive manufacturing's design flexibility and material efficiency, enabling complex geometries and rapid prototyping. This integration enhances production capabilities, reduces lead times, and optimizes resource utilization in advanced manufacturing environments.

5-Axis Machining

5-Axis machining enhances traditional manufacturing by enabling complex geometries and precise cuts on multiple axes simultaneously, significantly improving efficiency and surface finish. Compared to additive manufacturing, 5-Axis machining excels in producing high-strength parts with superior material properties and tighter tolerances, making it ideal for aerospace, automotive, and medical applications.

Laser Powder Bed Fusion (LPBF)

Traditional machining relies on subtractive processes, removing material from a solid block, which can lead to significant waste and longer production times, while Laser Powder Bed Fusion (LPBF) in additive manufacturing builds parts layer-by-layer using a laser to fuse metal powder, optimizing material usage and enabling complex geometries. LPBF technology enhances manufacturing flexibility, reduces lead times, and improves customization capabilities compared to conventional machining methods.

Directed Energy Deposition (DED)

Directed Energy Deposition (DED) in additive manufacturing enables precise metal repair and complex part fabrication by melting materials with focused energy sources, outperforming traditional machining in material efficiency and geometric complexity. Traditional machining relies on subtractive processes that often result in higher waste and limited ability to create intricate internal features compared to DED's layer-by-layer deposition capabilities.

Post-Processing Automation

Post-processing automation in traditional machining primarily involves CNC-dependent tasks such as deburring, surface finishing, and inspection that enhance precision while increasing production efficiency. Additive manufacturing leverages automated post-processing systems including support removal, heat treatment, and surface smoothing, significantly reducing manual labor and accelerating turnaround times for complex geometries.

Near-Net Shape Manufacturing

Near-net shape manufacturing in traditional machining involves subtractive processes like milling and turning to produce parts close to final dimensions, reducing material waste and machining time. Additive manufacturing achieves near-net shape by layering materials precisely, enabling complex geometries and minimizing material removal while enhancing design flexibility and production efficiency.

Toolpath Optimization

Traditional machining requires precise toolpath optimization to minimize cutting time and tool wear, ensuring efficient material removal and surface finish quality. Additive manufacturing leverages software-driven toolpath strategies to control layer deposition, reducing material waste and enabling complex geometries with optimized build times.

Support Structure Generation

Support structure generation in traditional machining is minimal, primarily involving fixtures and clamps to stabilize the workpiece, whereas additive manufacturing requires complex, computer-generated support structures to prevent deformation and ensure precision during the layer-by-layer build process. These supports are critical for overhangs and intricate geometries, but add post-processing time and material costs.

Digital Thread Integration

Traditional machining relies heavily on physical tooling and sequential processes, often limiting real-time data flow and integration within the manufacturing lifecycle; digital thread integration enhances additive manufacturing by enabling seamless data connectivity from design to production, improving traceability, process control, and customization capabilities. Leveraging IoT sensors and CAD/CAM interoperability, additive manufacturing with a robust digital thread supports agile pivoting and continuous feedback, driving superior product quality and reduced lead times compared to conventional machining methods.

Traditional Machining vs Additive Manufacturing Infographic

industrydif.com

industrydif.com