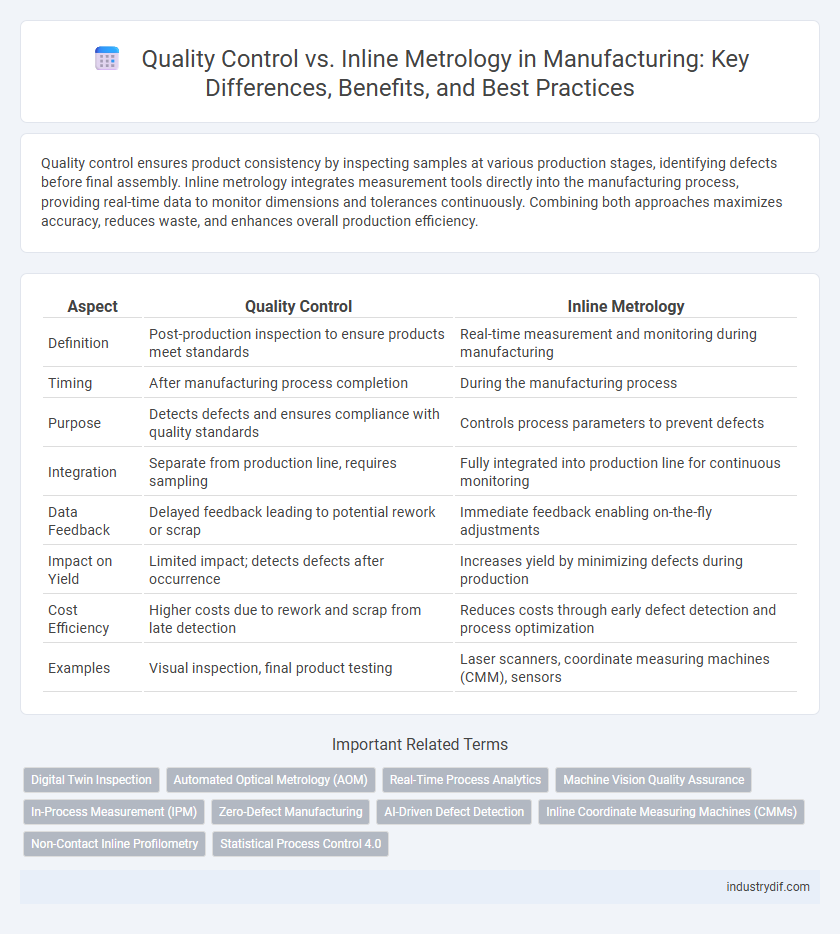

Quality control ensures product consistency by inspecting samples at various production stages, identifying defects before final assembly. Inline metrology integrates measurement tools directly into the manufacturing process, providing real-time data to monitor dimensions and tolerances continuously. Combining both approaches maximizes accuracy, reduces waste, and enhances overall production efficiency.

Table of Comparison

| Aspect | Quality Control | Inline Metrology |

|---|---|---|

| Definition | Post-production inspection to ensure products meet standards | Real-time measurement and monitoring during manufacturing |

| Timing | After manufacturing process completion | During the manufacturing process |

| Purpose | Detects defects and ensures compliance with quality standards | Controls process parameters to prevent defects |

| Integration | Separate from production line, requires sampling | Fully integrated into production line for continuous monitoring |

| Data Feedback | Delayed feedback leading to potential rework or scrap | Immediate feedback enabling on-the-fly adjustments |

| Impact on Yield | Limited impact; detects defects after occurrence | Increases yield by minimizing defects during production |

| Cost Efficiency | Higher costs due to rework and scrap from late detection | Reduces costs through early defect detection and process optimization |

| Examples | Visual inspection, final product testing | Laser scanners, coordinate measuring machines (CMM), sensors |

Introduction to Quality Control and Inline Metrology

Quality control in manufacturing involves systematic inspection and testing processes to ensure products meet predefined standards and customer expectations. Inline metrology integrates measurement technologies directly within the production line, enabling real-time monitoring and immediate defect detection. This approach reduces waste, increases process efficiency, and supports continuous quality improvement compared to traditional post-production quality control methods.

Defining Quality Control in Manufacturing

Quality Control in manufacturing refers to the systematic process of inspecting and testing products to ensure they meet predefined standards and specifications. It involves measuring critical dimensions, detecting defects, and verifying performance to maintain product consistency and reliability. This process helps reduce waste, minimize rework, and enhance customer satisfaction by guaranteeing that only quality-compliant products reach the market.

Understanding Inline Metrology Systems

Inline metrology systems integrate real-time measurement technology directly into the manufacturing process to monitor product dimensions and surface characteristics with high precision. This approach enables immediate detection of deviations from quality standards, reducing waste and minimizing rework compared to traditional quality control methods that rely on post-production inspection. Understanding inline metrology systems is essential for optimizing process control, enhancing product consistency, and achieving higher manufacturing efficiency.

Key Differences Between Quality Control and Inline Metrology

Quality Control involves the systematic inspection and testing of finished products to ensure they meet predefined standards, primarily focusing on defect detection after production. Inline Metrology integrates measurement systems directly into the manufacturing process, enabling real-time data collection and immediate feedback for process adjustments. The key difference lies in Quality Control's post-process evaluation versus Inline Metrology's continuous, in-process monitoring that enhances precision and reduces downtime.

Advantages of Traditional Quality Control Methods

Traditional quality control methods provide reliable defect detection through manual inspection and standardized testing procedures, ensuring consistent product quality in manufacturing environments. These methods allow flexibility in evaluating complex or customized components that may be challenging for automated systems to assess accurately. Established protocols and operator expertise contribute to rapid identification and resolution of quality issues, minimizing production downtime and waste.

Benefits of Implementing Inline Metrology

Inline metrology enhances manufacturing quality control by providing real-time, precise measurements during the production process, reducing defects and rework. This immediate data feedback enables faster decision-making and process adjustments, leading to increased efficiency and product consistency. Implementing inline metrology decreases inspection time and costs, ensuring higher yields and improved compliance with industry standards.

Challenges in Adopting Inline Metrology Technologies

Challenges in adopting inline metrology technologies in manufacturing include high initial investment costs and integration complexities with existing production lines. Ensuring real-time data accuracy and managing large volumes of measurement data also pose significant hurdles. Resistance to change from quality control teams accustomed to traditional inspection methods further complicates implementation.

Integration of Quality Control and Inline Metrology

Integrating Quality Control and Inline Metrology enhances manufacturing precision by enabling real-time monitoring and immediate correction of production deviations. This integration leverages high-resolution sensors and automated data analysis to ensure consistent product specifications while reducing waste and downtime. Advanced inline metrology systems combined with robust quality control protocols streamline process optimization and support continuous improvement initiatives in manufacturing environments.

Impact on Production Efficiency and Product Quality

Quality control ensures product conformity through systematic inspections, reducing defects and rework rates in manufacturing processes. Inline metrology integrates real-time measurements within production lines, enabling immediate adjustments that enhance production efficiency and maintain consistent product quality. Implementing inline metrology reduces downtime and scrap rates, directly improving operational effectiveness and customer satisfaction.

Future Trends in Quality Control and Inline Metrology

Future trends in quality control emphasize the integration of advanced AI-driven analytics and real-time data processing to enhance defect detection accuracy and reduce production downtime. Inline metrology devices are evolving with higher precision sensors and automation compatibility, enabling continuous, non-destructive measurement within manufacturing lines. The convergence of Industry 4.0 technologies, such as IoT connectivity and machine learning algorithms, drives smarter, adaptive quality control systems that improve overall manufacturing efficiency and product consistency.

Related Important Terms

Digital Twin Inspection

Quality control ensures product conformity through traditional sampling and post-production checks, while inline metrology integrates real-time sensor data for continuous monitoring. Digital twin inspection leverages inline metrology to create a virtual replica of the manufacturing process, enabling predictive analytics and immediate identification of deviations to optimize product quality.

Automated Optical Metrology (AOM)

Automated Optical Metrology (AOM) integrates inline metrology directly into manufacturing lines, enabling real-time, non-contact measurements that significantly enhance defect detection and process control compared to traditional quality control methods. This continuous monitoring capability reduces production downtime and ensures higher precision in dimensional accuracy, leading to improved product quality and consistency.

Real-Time Process Analytics

Quality control ensures product conformity by inspecting final outputs, while inline metrology integrates sensors directly into manufacturing processes for continuous, real-time process analytics. Real-time data from inline metrology enables immediate detection and correction of deviations, significantly reducing defects and enhancing overall manufacturing efficiency.

Machine Vision Quality Assurance

Machine vision quality assurance enhances inline metrology by providing real-time, non-contact inspection with high precision, enabling rapid defect detection and process control in manufacturing lines. Unlike traditional quality control that relies on intermittent sampling, inline metrology integrated with machine vision ensures continuous monitoring, improving product consistency and reducing waste.

In-Process Measurement (IPM)

In-process measurement (IPM) enhances manufacturing precision by integrating inline metrology directly into the production line, enabling real-time quality control and immediate defect detection. Unlike traditional quality control methods that inspect products post-production, inline metrology offers continuous monitoring of critical dimensions and tolerances, reducing scrap rates and improving overall product consistency.

Zero-Defect Manufacturing

Quality control ensures product compliance through post-production inspections, while inline metrology integrates real-time measurements during manufacturing to detect deviations immediately. Implementing inline metrology within zero-defect manufacturing frameworks significantly reduces error rates and enhances process efficiency.

AI-Driven Defect Detection

AI-driven defect detection in manufacturing enhances quality control by providing real-time analysis and instant feedback, reducing human error and improving accuracy. Inline metrology integrates advanced sensors and machine learning algorithms directly into production lines, enabling continuous monitoring and immediate correction of defects to optimize product quality.

Inline Coordinate Measuring Machines (CMMs)

Inline Coordinate Measuring Machines (CMMs) revolutionize quality control in manufacturing by providing real-time, high-precision measurements directly on the production line, minimizing defects and reducing inspection cycle times. Unlike traditional quality control methods, inline metrology with CMMs ensures continuous dimensional accuracy, enabling immediate corrective actions and enhancing overall product consistency.

Non-Contact Inline Profilometry

Non-contact inline profilometry significantly enhances quality control in manufacturing by providing real-time, precise surface measurements without halting production processes. This technology improves defect detection and dimensional accuracy, leading to higher product reliability and reduced waste compared to traditional quality control methods.

Statistical Process Control 4.0

Statistical Process Control 4.0 integrates advanced inline metrology techniques with real-time quality control data, enabling manufacturers to detect process variations and defects immediately during production. This synergy enhances product consistency, reduces waste, and drives continuous improvement by leveraging AI-powered analytics and IoT-connected sensors for precise measurement and process optimization.

Quality Control vs Inline Metrology Infographic

industrydif.com

industrydif.com