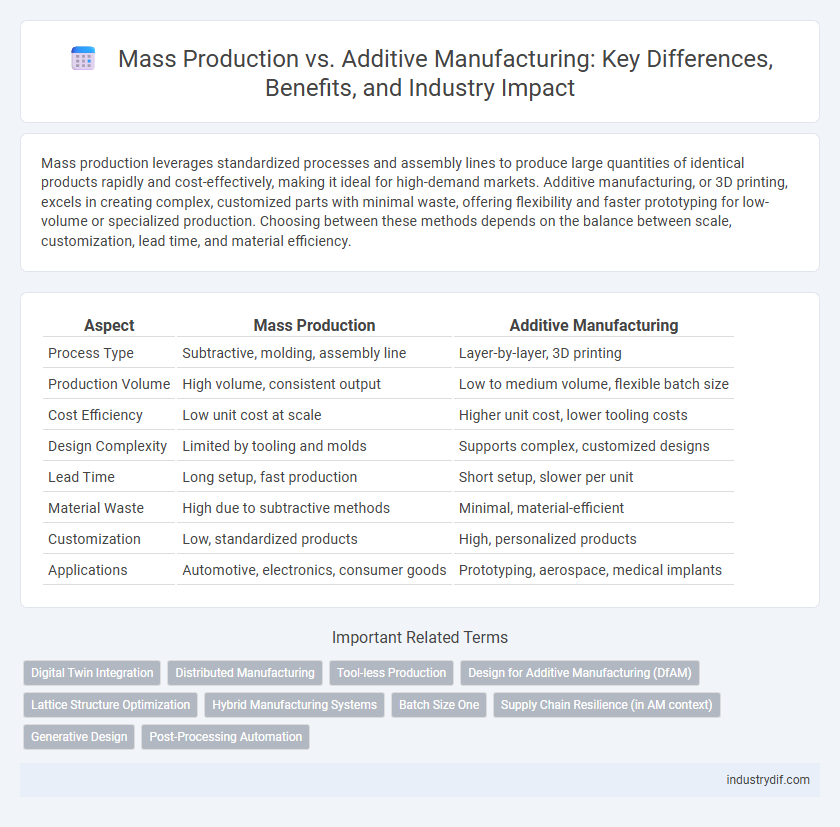

Mass production leverages standardized processes and assembly lines to produce large quantities of identical products rapidly and cost-effectively, making it ideal for high-demand markets. Additive manufacturing, or 3D printing, excels in creating complex, customized parts with minimal waste, offering flexibility and faster prototyping for low-volume or specialized production. Choosing between these methods depends on the balance between scale, customization, lead time, and material efficiency.

Table of Comparison

| Aspect | Mass Production | Additive Manufacturing |

|---|---|---|

| Process Type | Subtractive, molding, assembly line | Layer-by-layer, 3D printing |

| Production Volume | High volume, consistent output | Low to medium volume, flexible batch size |

| Cost Efficiency | Low unit cost at scale | Higher unit cost, lower tooling costs |

| Design Complexity | Limited by tooling and molds | Supports complex, customized designs |

| Lead Time | Long setup, fast production | Short setup, slower per unit |

| Material Waste | High due to subtractive methods | Minimal, material-efficient |

| Customization | Low, standardized products | High, personalized products |

| Applications | Automotive, electronics, consumer goods | Prototyping, aerospace, medical implants |

Understanding Mass Production in Modern Manufacturing

Mass production in modern manufacturing relies on large-scale, standardized processes using assembly lines to produce high volumes of identical products efficiently and cost-effectively. This method leverages economies of scale, automation, and specialized machinery to minimize per-unit costs and ensure consistent quality across batches. Understanding these core principles is essential for optimizing production workflows and meeting market demand in industries such as automotive, consumer electronics, and appliances.

Defining Additive Manufacturing: Key Concepts

Additive Manufacturing (AM), commonly referred to as 3D printing, involves creating objects layer by layer from digital models, contrasting with traditional mass production's subtractive or formative methods. Key concepts include material extrusion, powder bed fusion, and vat photopolymerization, enabling complex geometries and customization impossible with mass production. AM's digital workflow streamlines prototyping and small batch production, driving innovation across aerospace, automotive, and healthcare industries.

Historical Evolution of Manufacturing Processes

Mass production emerged during the Industrial Revolution, revolutionizing manufacturing with assembly line techniques that enabled high-volume output and cost efficiency. Additive manufacturing, developed in the late 20th century, introduced layer-by-layer 3D printing, allowing unprecedented customization and rapid prototyping. The historical evolution from traditional subtractive methods to additive processes reflects ongoing advancements in material science, automation, and digital technologies.

Core Benefits of Mass Production Techniques

Mass production techniques offer unparalleled efficiency in producing large volumes of uniform products, significantly reducing per-unit costs and lead times. Standardized assembly lines streamline workflow, ensuring high consistency and quality control across batches. The scalability of mass production makes it ideal for industries requiring rapid fulfillment of extensive market demand.

Advantages of Additive Manufacturing Technologies

Additive manufacturing technologies offer significant advantages such as customization, rapid prototyping, and reduced material waste compared to traditional mass production methods. These technologies enable the production of complex geometries that are difficult or impossible to achieve with conventional subtractive processes. The flexibility of additive manufacturing also shortens the product development cycle, allowing for faster innovation and decreased time-to-market.

Material Selection: Mass Production vs Additive Manufacturing

Material selection in mass production typically prioritizes cost-effective, standardized materials such as metals and plastics suitable for high-volume molding or stamping processes. Additive manufacturing allows for a broader range of materials, including complex alloys, composites, and biocompatible substances, enabling customization and material optimization at a layer-by-layer level. This flexibility supports innovation in lightweight structures and functional gradients that are challenging to achieve with traditional mass production methods.

Design Flexibility and Customization Capabilities

Mass production excels at producing large volumes of standardized products with low unit costs but offers limited design flexibility and customization options. Additive manufacturing enables complex geometries and rapid prototyping, supporting high levels of design innovation and tailored product variations. This technology significantly reduces tooling constraints, allowing manufacturers to customize products to specific customer requirements without expensive retooling.

Cost Efficiency and Production Scaling Analysis

Mass production offers superior cost efficiency for high-volume manufacturing due to economies of scale, significantly lowering per-unit costs through standardization and automation. Additive manufacturing excels in production scaling flexibility, enabling low-volume, customized parts without the need for expensive tooling or molds. Evaluating cost efficiency requires balancing the initial capital investment of mass production against the variable, material-driven expenses of additive manufacturing for rapid prototyping and small batch runs.

Industry Applications: Comparing Use Cases

Mass production excels in large-scale manufacturing of standardized products such as automotive parts and consumer electronics, where efficiency and cost reduction are critical. Additive manufacturing is preferred in aerospace and medical industries for producing complex, customized components like aircraft brackets and patient-specific implants that require precision and design flexibility. Companies combine both methods to optimize production workflows, leveraging mass production for high-volume output and additive manufacturing for prototyping and low-volume, intricate parts.

Future Trends in Manufacturing: Integration and Innovation

Mass production continues to leverage economies of scale for high-volume, standardized products, while additive manufacturing drives customization and rapid prototyping through layer-by-layer fabrication. Future trends in manufacturing emphasize the integration of Industry 4.0 technologies such as IoT, AI, and digital twins to optimize production workflows and enhance real-time decision-making. Hybrid manufacturing systems combining mass production efficiency with additive flexibility are emerging as key innovations to meet evolving market demands.

Related Important Terms

Digital Twin Integration

Mass production leverages standardized processes optimized through digital twin integration to enhance efficiency and predictability in high-volume outputs, enabling real-time monitoring and rapid defect detection. Additive manufacturing benefits from digital twins by simulating complex part geometries and process parameters, allowing for precise customization and iterative design improvements without interrupting the physical production flow.

Distributed Manufacturing

Mass production relies on centralized facilities to produce large volumes of standardized products, while additive manufacturing supports distributed manufacturing by enabling on-demand, localized production with reduced inventory and transportation costs. Distributed manufacturing leverages additive manufacturing technologies such as 3D printing to enhance supply chain flexibility, reduce lead times, and allow for rapid customization in diverse geographic locations.

Tool-less Production

Mass production relies on traditional tooling processes that require molds and dies, leading to high upfront costs and longer lead times, whereas additive manufacturing enables tool-less production by building components layer-by-layer directly from digital designs. This eliminates the need for expensive tooling, reduces waste, and allows for rapid prototyping and customization, revolutionizing efficiency and flexibility in manufacturing workflows.

Design for Additive Manufacturing (DfAM)

Design for Additive Manufacturing (DfAM) emphasizes optimizing product designs to leverage the layer-by-layer construction of 3D printing, enabling intricate geometries and lightweight structures unattainable in mass production methods like injection molding or CNC machining. By integrating DfAM principles, manufacturers reduce material waste, shorten lead times, and enhance customization, contrasting traditional mass production's focus on economies of scale and standardized tooling.

Lattice Structure Optimization

Mass production typically relies on traditional subtractive methods that limit lattice structure complexity, whereas additive manufacturing enables precise lattice structure optimization, significantly enhancing material efficiency and mechanical performance. Optimizing lattice structures through additive manufacturing reduces weight while maintaining strength, driving innovations in aerospace, automotive, and biomedical industries.

Hybrid Manufacturing Systems

Hybrid manufacturing systems integrate mass production's high-volume output with additive manufacturing's precision and customization, enabling efficient production of complex parts with reduced lead times. These systems leverage the scalability of traditional manufacturing while incorporating layer-by-layer material addition to optimize resource use and enhance product functionality.

Batch Size One

Mass production excels in high-volume output with economies of scale, while additive manufacturing enables cost-effective customization and flexibility for batch size one production. Additive manufacturing's capability to produce complex, tailored parts on demand reduces lead times and inventory costs compared to traditional mass production methods.

Supply Chain Resilience (in AM context)

Additive manufacturing enhances supply chain resilience by enabling decentralized production, reducing dependency on long lead times and complex logistics inherent in mass production. Its capability for rapid prototyping and on-demand manufacturing minimizes inventory risks and adapts swiftly to disruptions, ensuring continuous product availability.

Generative Design

Generative design leverages advanced algorithms to optimize component geometry, enabling additive manufacturing to produce lightweight, complex parts unattainable through traditional mass production methods. This approach reduces material waste and accelerates product development cycles, offering significant advantages in customization and efficiency compared to conventional manufacturing processes.

Post-Processing Automation

In manufacturing, mass production relies heavily on automated post-processing techniques like CNC machining and surface finishing robots to ensure consistent quality at high volumes, whereas additive manufacturing benefits from emerging post-processing automation such as robotic support removal and automated heat treatment to enhance efficiency and scalability. Integrating intelligent post-processing systems in additive manufacturing reduces manual labor and cycle times, enabling faster production of complex, customized parts compared to traditional subtractive post-processing methods used in mass production.

Mass Production vs Additive Manufacturing Infographic

industrydif.com

industrydif.com