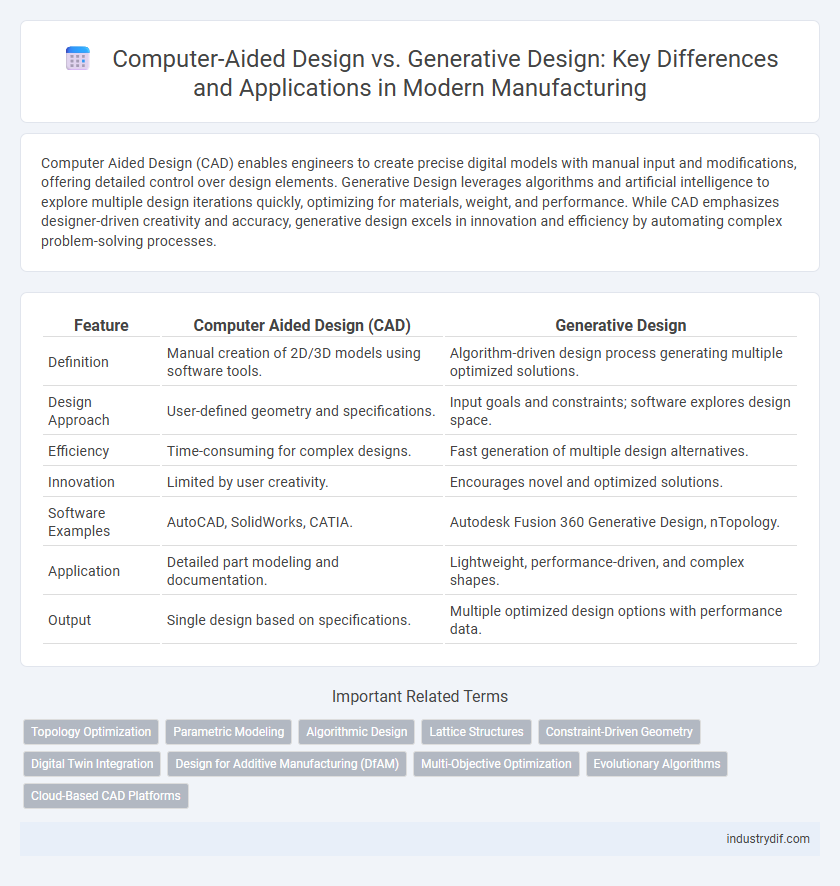

Computer Aided Design (CAD) enables engineers to create precise digital models with manual input and modifications, offering detailed control over design elements. Generative Design leverages algorithms and artificial intelligence to explore multiple design iterations quickly, optimizing for materials, weight, and performance. While CAD emphasizes designer-driven creativity and accuracy, generative design excels in innovation and efficiency by automating complex problem-solving processes.

Table of Comparison

| Feature | Computer Aided Design (CAD) | Generative Design |

|---|---|---|

| Definition | Manual creation of 2D/3D models using software tools. | Algorithm-driven design process generating multiple optimized solutions. |

| Design Approach | User-defined geometry and specifications. | Input goals and constraints; software explores design space. |

| Efficiency | Time-consuming for complex designs. | Fast generation of multiple design alternatives. |

| Innovation | Limited by user creativity. | Encourages novel and optimized solutions. |

| Software Examples | AutoCAD, SolidWorks, CATIA. | Autodesk Fusion 360 Generative Design, nTopology. |

| Application | Detailed part modeling and documentation. | Lightweight, performance-driven, and complex shapes. |

| Output | Single design based on specifications. | Multiple optimized design options with performance data. |

Introduction to Computer Aided Design (CAD) and Generative Design

Computer Aided Design (CAD) software enables precise 2D and 3D modeling of products, streamlining the product development process by allowing detailed drafting, simulation, and revision before physical prototypes. Generative Design leverages algorithms and artificial intelligence to produce multiple optimized design alternatives based on specified constraints such as material, weight, and cost. While CAD focuses on manual creation and modification, generative design automates innovation by exploring complex geometries that maximize performance and efficiency in manufacturing.

Core Principles of CAD in Manufacturing

Computer Aided Design (CAD) in manufacturing centers on precise geometric modeling, enabling detailed digital representations of components and assemblies for accurate production. CAD systems utilize parametric and feature-based modeling to streamline design modifications, ensuring consistency and efficiency throughout the manufacturing process. Integration with CAM (Computer Aided Manufacturing) and simulation tools enhances error detection and optimizes workflow from design to fabrication.

Overview of Generative Design in Industry

Generative design in manufacturing leverages advanced algorithms and artificial intelligence to create optimized product designs based on defined constraints and performance goals. This approach enables the rapid exploration of numerous design alternatives, resulting in innovative and lightweight structures that traditional Computer Aided Design (CAD) methods may not identify. Manufacturers benefit from reduced material usage, enhanced product performance, and accelerated development cycles through the integration of generative design into their workflows.

Differences Between CAD and Generative Design Workflows

Computer Aided Design (CAD) workflows rely on manual input and precise control, enabling engineers to create detailed 2D or 3D models based on predefined specifications. Generative Design utilizes algorithms and artificial intelligence to explore a vast range of design possibilities, optimizing materials and performance by iteratively generating and evaluating multiple solutions. Unlike CAD's deterministic approach, generative design workflows prioritize computational creativity and automation, significantly reducing design time and improving innovation in manufacturing processes.

Design Flexibility: CAD vs Generative Algorithms

Computer Aided Design (CAD) offers precise control and predefined parameters, enabling engineers to create detailed and accurate models based on exact specifications. Generative design algorithms leverage artificial intelligence to explore a vast array of design possibilities, automatically optimizing for factors like material usage, weight, and performance. This results in greater design flexibility as generative methods can produce innovative, unconventional structures that traditional CAD tools may not easily achieve.

Impact on Product Development Lifecycles

Computer Aided Design (CAD) streamlines product development by enabling precise modeling and easy modifications, reducing prototyping time and costs. Generative Design leverages AI algorithms to explore numerous design alternatives, optimizing for performance, materials, and manufacturing constraints, significantly accelerating innovation cycles. Together, these technologies shorten product development lifecycles by enhancing design accuracy and enabling rapid iteration.

Material Optimization and Sustainability

Computer Aided Design (CAD) enables precise control over product geometry, facilitating efficient material use, but often relies on designer input for optimization. Generative Design employs AI-driven algorithms to explore numerous design alternatives, maximizing material efficiency and minimizing waste through topology optimization. This approach enhances sustainability by reducing raw material consumption and lowering environmental impact across the manufacturing lifecycle.

Integration with Advanced Manufacturing Technologies

Computer Aided Design (CAD) offers precise modeling capabilities essential for traditional manufacturing processes like CNC machining and 3D printing, ensuring compatibility with standard fabrication methods. Generative Design leverages algorithm-driven optimizations that seamlessly integrate with advanced manufacturing technologies such as additive manufacturing and robotics, enabling the production of complex, lightweight structures with enhanced performance. This integration accelerates prototyping cycles and facilitates the creation of innovative components that conventional CAD workflows may not easily achieve.

Skillset and Learning Curve Comparison

Computer Aided Design (CAD) requires proficiency in traditional drafting techniques and software tools like AutoCAD or SolidWorks, emphasizing precise manual control and extensive experience in geometry and engineering principles. Generative Design involves advanced skills in algorithms, artificial intelligence, and machine learning, demanding familiarity with platforms such as Autodesk Fusion 360's generative workspace and a deeper understanding of computational design principles. The learning curve for CAD is typically moderate due to established training resources and clear workflows, while Generative Design poses a steeper curve as it integrates complex optimization processes and iterative simulation methods.

Future Trends: The Evolution of Design Tools in Manufacturing

Future trends in manufacturing emphasize the shift from traditional Computer Aided Design (CAD) to Generative Design, leveraging artificial intelligence and machine learning to optimize complex geometries and material usage. Generative Design accelerates innovation by automatically producing multiple design alternatives based on specified constraints, enabling manufacturers to reduce production costs and improve product performance. The integration of cloud computing and real-time data analytics further enhances these tools, driving smarter, more sustainable manufacturing processes.

Related Important Terms

Topology Optimization

Topology optimization in computer-aided design (CAD) focuses on refining existing structures within predefined constraints, whereas generative design leverages advanced algorithms to explore innovative shapes and configurations beyond conventional limits. Generative design integrates topology optimization by iteratively removing inefficient material, resulting in lightweight, high-strength components optimized for manufacturing feasibility and performance.

Parametric Modeling

Parametric modeling in Computer Aided Design (CAD) enables precise control over design parameters, allowing modifications through adjustable variables that maintain geometric relationships, while Generative Design leverages algorithms to explore a vast range of design possibilities based on specified constraints and objectives. Unlike traditional parametric CAD, generative design automates iteration and optimization, enhancing innovation and efficiency in manufacturing workflows.

Algorithmic Design

Algorithmic design leverages predefined rules and parameters to create precise, repeatable CAD models, optimizing efficiency in traditional engineering workflows. Generative design employs AI-driven algorithms to explore vast design possibilities, producing innovative, performance-driven solutions beyond conventional constraints.

Lattice Structures

Computer Aided Design (CAD) enables precise modeling of lattice structures with predefined geometries, while Generative Design uses algorithms to optimize lattice patterns for weight reduction and strength enhancement. Lattice structures designed through generative methods exhibit improved material efficiency and mechanical performance compared to traditional CAD approaches.

Constraint-Driven Geometry

Constraint-driven geometry in Computer Aided Design (CAD) enables precise control over design parameters by allowing engineers to define exact dimensions and relationships, ensuring conformity to manufacturing specifications. In contrast, Generative Design leverages algorithms and constraints to explore a vast design space, producing optimized geometries that balance performance, material usage, and manufacturability beyond traditional CAD capabilities.

Digital Twin Integration

Computer Aided Design (CAD) streamlines traditional manufacturing by enabling precise modeling and prototyping, while Generative Design leverages AI algorithms to create optimized structures based on defined constraints. Integrating Digital Twin technology enhances both CAD and Generative Design by providing real-time simulation and performance feedback, accelerating iteration cycles and improving product reliability in manufacturing processes.

Design for Additive Manufacturing (DfAM)

Computer Aided Design (CAD) allows precise control over geometry for traditional manufacturing but often requires extensive manual adjustments for Additive Manufacturing (AM). Generative Design leverages AI algorithms to optimize component structures specifically for AM constraints, enhancing material efficiency and mechanical performance in Design for Additive Manufacturing (DfAM).

Multi-Objective Optimization

Computer Aided Design (CAD) provides precise control over geometry creation, allowing designers to manually adjust features, while Generative Design leverages advanced algorithms to explore numerous design alternatives simultaneously through multi-objective optimization, balancing factors such as weight, strength, and cost. Multi-objective optimization in Generative Design enhances manufacturing efficiency by automatically identifying optimal trade-offs, resulting in innovative, performance-driven components tailored to specific production constraints.

Evolutionary Algorithms

Generative Design leverages evolutionary algorithms to iteratively optimize manufacturing components by simulating natural selection processes, resulting in innovative, lightweight, and efficient structures unattainable through traditional Computer Aided Design (CAD) methods. These algorithms enhance design exploration by evaluating thousands of variations based on performance criteria, accelerating product development cycles and reducing material waste.

Cloud-Based CAD Platforms

Cloud-based CAD platforms offer real-time collaboration and seamless integration with generative design algorithms, enabling faster iteration and optimization of complex manufacturing parts. Unlike traditional computer aided design, generative design leverages cloud computing power to explore numerous design alternatives, reducing material waste and improving performance efficiency.

Computer Aided Design vs Generative Design Infographic

industrydif.com

industrydif.com