Assembly line manufacturing relies on manual labor and sequential processes to assemble products, ensuring flexibility and human oversight in quality control. Lights-out manufacturing operates autonomously with minimal human intervention, using robotics and automation to increase efficiency, reduce errors, and enable 24/7 production. Choosing between these methods depends on production volume, complexity, and the need for customization versus speed and consistency.

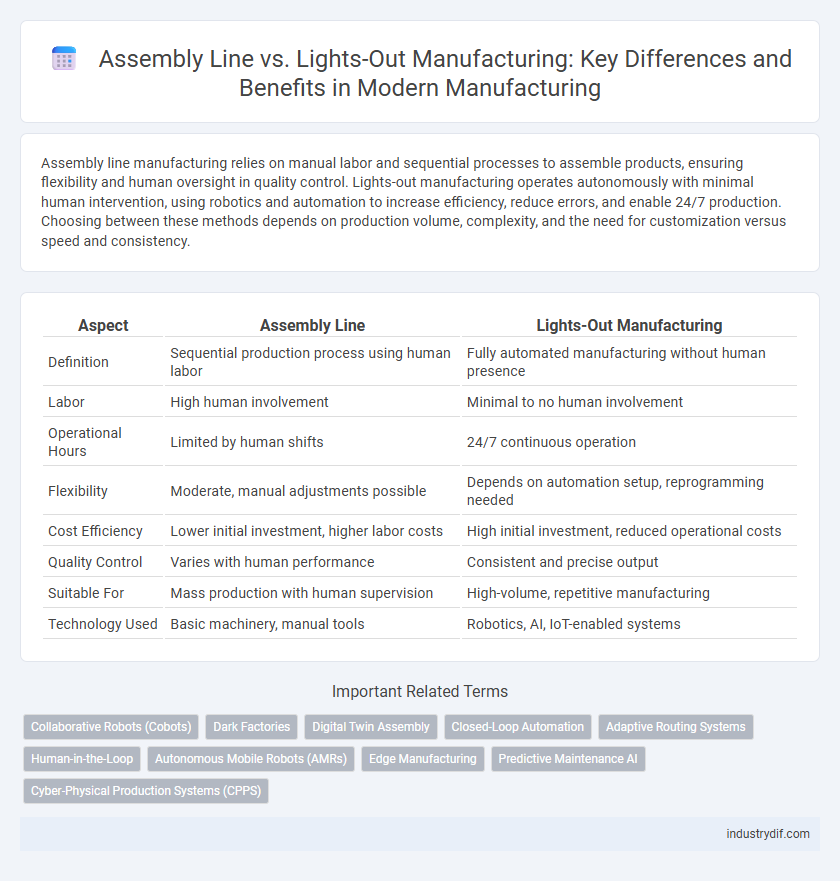

Table of Comparison

| Aspect | Assembly Line | Lights-Out Manufacturing |

|---|---|---|

| Definition | Sequential production process using human labor | Fully automated manufacturing without human presence |

| Labor | High human involvement | Minimal to no human involvement |

| Operational Hours | Limited by human shifts | 24/7 continuous operation |

| Flexibility | Moderate, manual adjustments possible | Depends on automation setup, reprogramming needed |

| Cost Efficiency | Lower initial investment, higher labor costs | High initial investment, reduced operational costs |

| Quality Control | Varies with human performance | Consistent and precise output |

| Suitable For | Mass production with human supervision | High-volume, repetitive manufacturing |

| Technology Used | Basic machinery, manual tools | Robotics, AI, IoT-enabled systems |

Introduction to Assembly Line and Lights-Out Manufacturing

Assembly line manufacturing streamlines production by organizing tasks sequentially along a conveyor system, enabling high-volume output and consistent product quality. Lights-out manufacturing operates autonomously without human intervention, utilizing advanced robotics and AI to maximize efficiency, reduce labor costs, and allow round-the-clock production. Both methods enhance operational workflows but differ in automation level, with assembly lines requiring human oversight and lights-out systems functioning fully automated.

Defining Assembly Line Manufacturing

Assembly line manufacturing involves a sequential production process where workers and machines perform specific tasks at designated stations, optimizing efficiency and consistency in mass production. This method relies heavily on human labor combined with mechanization to assemble components into finished products. The structured flow reduces production time and costs, making it ideal for high-volume manufacturing environments.

Understanding Lights-Out Manufacturing

Lights-out manufacturing refers to fully automated production processes operated without human presence, significantly reducing labor costs and minimizing error rates. This approach leverages advanced robotics, AI-driven systems, and IoT connectivity to maintain continuous, efficient workflows, enhancing throughput and consistency compared to traditional assembly line setups. The implementation of lights-out manufacturing facilitates 24/7 operations, optimizing resource utilization and accelerating time-to-market for complex manufacturing tasks.

Key Differences Between Assembly Line and Lights-Out Manufacturing

Assembly line manufacturing involves human workers performing specific tasks in a sequential process to assemble products, emphasizing manual labor and quality control at each station. Lights-out manufacturing operates with fully automated systems, enabling continuous production without human intervention, which reduces labor costs and increases efficiency. The key differences lie in workforce involvement, operational hours, and the level of automation integrated into the manufacturing process.

Historical Evolution of Manufacturing Processes

Assembly line manufacturing revolutionized mass production in the early 20th century by introducing sequential task specialization, dramatically increasing efficiency and output. Lights-out manufacturing, emerging in the late 20th and early 21st centuries, leverages automation and robotics to enable fully unattended operations, reducing labor costs and minimizing human error. The historical evolution from manual assembly lines to autonomous lights-out facilities reflects the industry's pursuit of higher precision, scalability, and continuous production capabilities.

Technology and Automation in Manufacturing

Assembly lines leverage human labor combined with mechanized tools to optimize productivity, while lights-out manufacturing employs fully automated systems operating without human intervention, maximizing efficiency and reducing errors. Advanced robotics, AI, and IoT sensors enable lights-out manufacturing to run continuously, facilitating real-time monitoring and predictive maintenance. This integration of cutting-edge automation technologies transforms manufacturing processes, driving higher throughput, lower operational costs, and enhanced precision.

Cost Implications: Assembly Line vs Lights-Out

Assembly line manufacturing involves significant labor costs, including wages, benefits, and training expenses, while lights-out manufacturing drastically reduces these by operating fully automated systems with minimal human intervention. Although initial capital investment for lights-out manufacturing, such as robotics and advanced control systems, can be substantial, the long-term operational costs are lower due to increased efficiency, reduced errors, and diminished downtime. Cost implications favor lights-out manufacturing when production volume and product complexity justify automation, resulting in enhanced scalability and decreased per-unit costs compared to traditional assembly lines.

Workforce Impact and Skill Requirements

Assembly line manufacturing relies heavily on manual labor, requiring a workforce skilled in repetitive tasks and basic machine operation, which can lead to workforce fatigue and turnover. Lights-out manufacturing minimizes human intervention by utilizing advanced robotics and automation, demanding a smaller, highly specialized workforce proficient in programming, maintenance, and system monitoring. The shift towards lights-out manufacturing significantly changes skill requirements, emphasizing advanced technical expertise over manual assembly skills.

Quality Control and Efficiency Comparison

Assembly lines offer consistent quality control through human oversight, enabling quick identification and correction of defects during production. Lights-out manufacturing leverages fully automated systems with sensors and AI-driven inspection, reducing variability and increasing efficiency by operating continuously without human intervention. Efficiency gains in lights-out manufacturing often surpass assembly lines due to minimized downtime and enhanced precision in quality control processes.

Future Trends in Manufacturing: From Assembly Lines to Lights-Out

Future trends in manufacturing emphasize the transition from traditional assembly lines to lights-out manufacturing, where fully automated factories operate autonomously without human intervention. Advances in robotics, artificial intelligence, and IoT enable continuous, high-precision production while reducing labor costs and human error. This shift drives increased efficiency, scalability, and sustainability in manufacturing operations worldwide.

Related Important Terms

Collaborative Robots (Cobots)

Collaborative robots (cobots) enhance assembly line efficiency by working alongside human operators to perform repetitive tasks with precision and adaptability, reducing errors and increasing throughput. In lights-out manufacturing, cobots operate autonomously in fully automated environments, enabling continuous production without human intervention and maximizing operational uptime.

Dark Factories

Dark factories, or lights-out manufacturing facilities, operate autonomously without human intervention, utilizing advanced robotics and AI to enhance precision and efficiency in assembly lines. This approach drastically reduces labor costs and error rates compared to traditional assembly lines, enabling continuous, 24/7 production in a controlled environment that maximizes output and minimizes downtime.

Digital Twin Assembly

Digital Twin Assembly enhances assembly line efficiency by creating a virtual replica of the physical production process, enabling real-time monitoring, predictive maintenance, and process optimization. Lights-Out Manufacturing leverages these digital twins to achieve fully automated, unattended operations, reducing human error and maximizing throughput in smart factories.

Closed-Loop Automation

Closed-loop automation integrates real-time feedback systems in both assembly lines and lights-out manufacturing to enhance precision, reduce errors, and optimize production efficiency. Lights-out manufacturing leverages closed-loop controls more extensively, enabling fully autonomous operations without human intervention by continuously monitoring and adjusting processes.

Adaptive Routing Systems

Adaptive routing systems in assembly lines optimize workflow by dynamically adjusting the path of products through various stations, enhancing efficiency and reducing bottlenecks. In lights-out manufacturing, these systems integrate with automated machinery and AI-driven sensors to enable fully autonomous production with minimal human intervention and increased precision.

Human-in-the-Loop

Human-in-the-loop assembly lines rely on skilled workers to perform complex tasks, ensuring quality control and adaptability in manufacturing processes. In contrast, lights-out manufacturing minimizes human intervention by utilizing fully automated systems, which enhances efficiency but limits real-time human decision-making and problem-solving.

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) enhance assembly line efficiency by automating material transport, reducing human intervention, and minimizing downtime through adaptive navigation in complex factory environments. In lights-out manufacturing, AMRs enable fully autonomous production cycles by seamlessly integrating with robotic systems for 24/7 operations, improving throughput and lowering labor costs.

Edge Manufacturing

Edge manufacturing integrates real-time data processing at the assembly line, enhancing precision and reducing latency compared to traditional centralized systems. Lights-out manufacturing leverages this edge technology to enable fully automated, unmanned production environments, significantly improving efficiency and minimizing human intervention.

Predictive Maintenance AI

Predictive Maintenance AI in assembly lines leverages real-time data to forecast equipment failures, reducing downtime and improving operational efficiency, while Lights-Out Manufacturing fully automates production with minimal human intervention, relying heavily on AI algorithms to predict and prevent machinery breakdowns. Implementing advanced predictive analytics enables both manufacturing methods to optimize maintenance schedules, enhance equipment lifespan, and maximize overall productivity.

Cyber-Physical Production Systems (CPPS)

Cyber-Physical Production Systems (CPPS) integrate advanced sensors, automation, and real-time data analytics to enhance both traditional assembly lines and lights-out manufacturing environments, enabling higher precision and efficiency. In assembly lines, CPPS optimize human-machine interaction and workflow, while in lights-out manufacturing, they facilitate fully autonomous operations with minimal human intervention, driving significant productivity gains.

Assembly Line vs Lights-Out Manufacturing Infographic

industrydif.com

industrydif.com