Supply Chain Management emphasizes the efficient coordination and integration of materials, information, and finances across the entire manufacturing process to optimize cost and delivery times. Resilient Supply Chain prioritizes flexibility and adaptability, ensuring manufacturing operations can quickly recover from disruptions such as supplier failures or demand fluctuations. Implementing resilient supply chain strategies strengthens risk management, minimizes downtime, and sustains continuous production flow in dynamic market conditions.

Table of Comparison

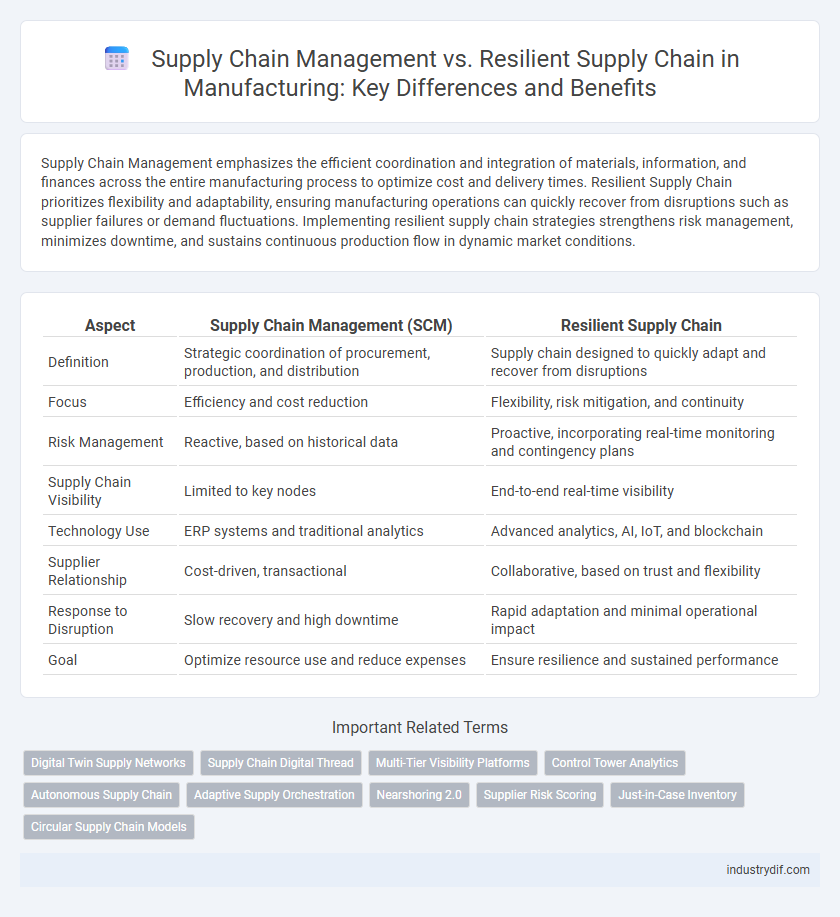

| Aspect | Supply Chain Management (SCM) | Resilient Supply Chain |

|---|---|---|

| Definition | Strategic coordination of procurement, production, and distribution | Supply chain designed to quickly adapt and recover from disruptions |

| Focus | Efficiency and cost reduction | Flexibility, risk mitigation, and continuity |

| Risk Management | Reactive, based on historical data | Proactive, incorporating real-time monitoring and contingency plans |

| Supply Chain Visibility | Limited to key nodes | End-to-end real-time visibility |

| Technology Use | ERP systems and traditional analytics | Advanced analytics, AI, IoT, and blockchain |

| Supplier Relationship | Cost-driven, transactional | Collaborative, based on trust and flexibility |

| Response to Disruption | Slow recovery and high downtime | Rapid adaptation and minimal operational impact |

| Goal | Optimize resource use and reduce expenses | Ensure resilience and sustained performance |

Overview of Supply Chain Management

Supply Chain Management (SCM) involves the coordination of materials, information, and finances as they move from supplier to manufacturer to wholesaler to retailer to consumer, aiming to optimize efficiency and reduce costs. It encompasses demand forecasting, inventory management, procurement, production scheduling, and logistics integration to ensure timely delivery and quality control. Resilient Supply Chains build on SCM principles by incorporating risk management strategies to adapt and respond effectively to disruptions.

Defining a Resilient Supply Chain

A resilient supply chain is designed to anticipate, prepare for, and respond swiftly to disruptions, ensuring continuous operations despite uncertainties. Unlike traditional supply chain management that emphasizes efficiency and cost reduction, resilience prioritizes flexibility, risk mitigation, and rapid recovery capabilities. Advanced technologies like AI-driven analytics and real-time monitoring enhance the resilience by enabling proactive decision-making and adaptive strategies.

Key Differences Between Traditional and Resilient Supply Chains

Traditional supply chain management emphasizes cost efficiency and lean inventory, often resulting in vulnerability to disruptions due to rigid processes and limited flexibility. Resilient supply chains prioritize adaptability, risk diversification, and rapid response mechanisms, integrating advanced technologies like AI and real-time data analytics to anticipate and mitigate potential supply shocks. The key difference lies in resilience-focused strategies that enhance continuity and recovery, ensuring sustained operations amidst global uncertainties.

Importance of Adaptability in Modern Manufacturing

Adaptability in modern manufacturing is crucial for efficient supply chain management, enabling companies to anticipate disruptions and respond swiftly to market changes. Resilient supply chains incorporate flexibility, real-time data analytics, and risk mitigation strategies to maintain continuous operations despite unforeseen challenges. Emphasizing adaptability ensures competitive advantage, minimizes downtime, and optimizes resource allocation in dynamic manufacturing environments.

Risk Management in Supply Chain Operations

Supply Chain Management (SCM) focuses on optimizing the flow of goods, information, and finances across suppliers, manufacturers, and distributors to improve efficiency and reduce costs. A Resilient Supply Chain emphasizes risk management by anticipating, responding to, and recovering from disruptions such as natural disasters, geopolitical conflicts, or supplier failures. Implementing risk assessment tools, real-time monitoring, and diversified sourcing strategies strengthens supply chain operations against volatility and uncertainty.

Technological Innovations Driving Resilience

Technological innovations such as AI-driven demand forecasting, IoT-enabled real-time tracking, and blockchain for transparent transactions are transforming supply chain management into resilient supply chains capable of adapting to disruptions. Advanced analytics optimize inventory levels and supplier selection, reducing vulnerability to uncertainties and enhancing operational agility. Digital twin simulations enable proactive risk assessment, fostering a robust manufacturing supply chain infrastructure that maintains continuity despite global challenges.

Lean Manufacturing vs. Resilient Supply Chain Approaches

Lean Manufacturing emphasizes minimizing waste and optimizing efficiency through streamlined processes and just-in-time inventory, which reduces costs but may increase vulnerability to disruptions. Resilient Supply Chain approaches prioritize flexibility and risk management by incorporating buffer stocks, diversified suppliers, and adaptive planning to maintain continuity during unforeseen events. Balancing lean principles with resilience strategies enables manufacturers to achieve cost-effectiveness while enhancing supply chain robustness against volatility.

Benefits of Building Supply Chain Resilience

Building supply chain resilience enhances a company's ability to withstand disruptions and maintain continuous operations, reducing risks associated with demand fluctuations, supplier failures, and geopolitical issues. Resilient supply chains improve flexibility by incorporating diversified sourcing, real-time data analytics, and adaptive inventory management strategies. These benefits lead to increased customer satisfaction, minimized financial losses, and a competitive advantage in dynamic manufacturing environments.

Case Studies: Manufacturing Supply Chain Failures and Successes

Case studies of manufacturing supply chain failures often highlight the consequences of rigid, non-resilient systems, such as the 2011 Toyota production halt due to the Japan earthquake, which exposed vulnerabilities in single-source suppliers. In contrast, companies like Cisco have demonstrated success through resilient supply chains by diversifying suppliers and implementing real-time data analytics to quickly adapt to disruptions. These examples emphasize the critical importance of flexibility, risk mitigation strategies, and digital integration in achieving supply chain resilience in manufacturing sectors.

Future Trends in Supply Chain Management for Manufacturers

Future trends in supply chain management for manufacturers emphasize the transition from traditional supply chain models to resilient supply chains that prioritize flexibility, risk mitigation, and real-time data analytics. Advanced technologies such as AI-driven demand forecasting, IoT-enabled inventory tracking, and blockchain for transparent transaction records enable manufacturers to anticipate disruptions and rapidly adjust operations. Sustainable practices and digital integration are increasingly central, driving efficiency and fostering resilience against geopolitical uncertainties and climate impacts.

Related Important Terms

Digital Twin Supply Networks

Digital Twin Supply Networks enhance Supply Chain Management by simulating real-time operations and predicting disruptions, enabling more responsive and adaptive strategies. This digital replication fosters a Resilient Supply Chain by optimizing demand forecasting, inventory management, and risk mitigation through advanced data analytics and AI-driven insights.

Supply Chain Digital Thread

Supply Chain Digital Thread integrates real-time data flow across procurement, production, and distribution, enhancing visibility and coordination in traditional Supply Chain Management. This continuous digital linkage is crucial for building a Resilient Supply Chain, enabling rapid response to disruptions through predictive analytics and adaptive decision-making.

Multi-Tier Visibility Platforms

Multi-tier visibility platforms enhance supply chain management by providing end-to-end transparency across multiple supplier tiers, enabling proactive risk identification and mitigation. Resilient supply chains leverage these platforms to improve agility and responsiveness, ensuring continuity amid disruptions and fluctuating market demands.

Control Tower Analytics

Control Tower Analytics enhances Supply Chain Management by providing real-time visibility and predictive insights that enable proactive decision-making. A Resilient Supply Chain leverages these analytics to quickly identify disruptions, optimize resource allocation, and maintain operational continuity under adverse conditions.

Autonomous Supply Chain

Autonomous supply chains leverage AI, IoT, and real-time data analytics to enhance decision-making, increase agility, and reduce human error compared to traditional supply chain management. This innovation drives resilience by enabling predictive maintenance, dynamic demand forecasting, and automated inventory optimization, ensuring continuous manufacturing operations despite disruptions.

Adaptive Supply Orchestration

Supply Chain Management focuses on efficient resource allocation and cost reduction, while resilient supply chains prioritize adaptive supply orchestration to swiftly respond to disruptions and maintain operational continuity. Adaptive supply orchestration integrates real-time data analytics and flexible procurement strategies, enhancing supply chain agility and risk mitigation in volatile manufacturing environments.

Nearshoring 2.0

Nearshoring 2.0 revolutionizes Supply Chain Management by shifting production closer to end markets, reducing lead times and mitigating global disruptions for a more resilient supply chain. This approach emphasizes strategic supplier localization and advanced technology integration to optimize inventory flow and enhance responsiveness in manufacturing operations.

Supplier Risk Scoring

Supplier risk scoring in supply chain management quantifies potential disruptions by evaluating factors like financial stability, geopolitical exposure, and delivery reliability. A resilient supply chain leverages dynamic supplier risk scores to proactively mitigate risks, ensuring sustained operational continuity amid fluctuating market conditions.

Just-in-Case Inventory

Just-in-case inventory enhances resilient supply chains by maintaining buffer stock to mitigate disruptions, unlike traditional supply chain management which often relies on just-in-time inventory to minimize costs. This strategic stockpiling improves responsiveness and reduces the risk of production delays caused by unforeseen supply interruptions in manufacturing.

Circular Supply Chain Models

Supply Chain Management optimizes the flow of materials through linear processes, whereas Resilient Supply Chains incorporate Circular Supply Chain Models to enhance sustainability by minimizing waste and enabling resource regeneration. Circular Supply Chain Models prioritize closed-loop systems, integrating reuse, remanufacturing, and recycling to increase supply chain agility and reduce environmental impact in manufacturing.

Supply Chain Management vs Resilient Supply Chain Infographic

industrydif.com

industrydif.com