Automation enhances manufacturing efficiency by streamlining repetitive tasks through fully automated systems, while cobots offer flexible collaboration by working alongside human operators to improve precision and safety. Integrating cobots enables manufacturers to maintain agility on production lines and adapt quickly to changing demands without extensive reprogramming. Balancing automation and cobot implementation drives productivity gains and fosters innovation within smart factory environments.

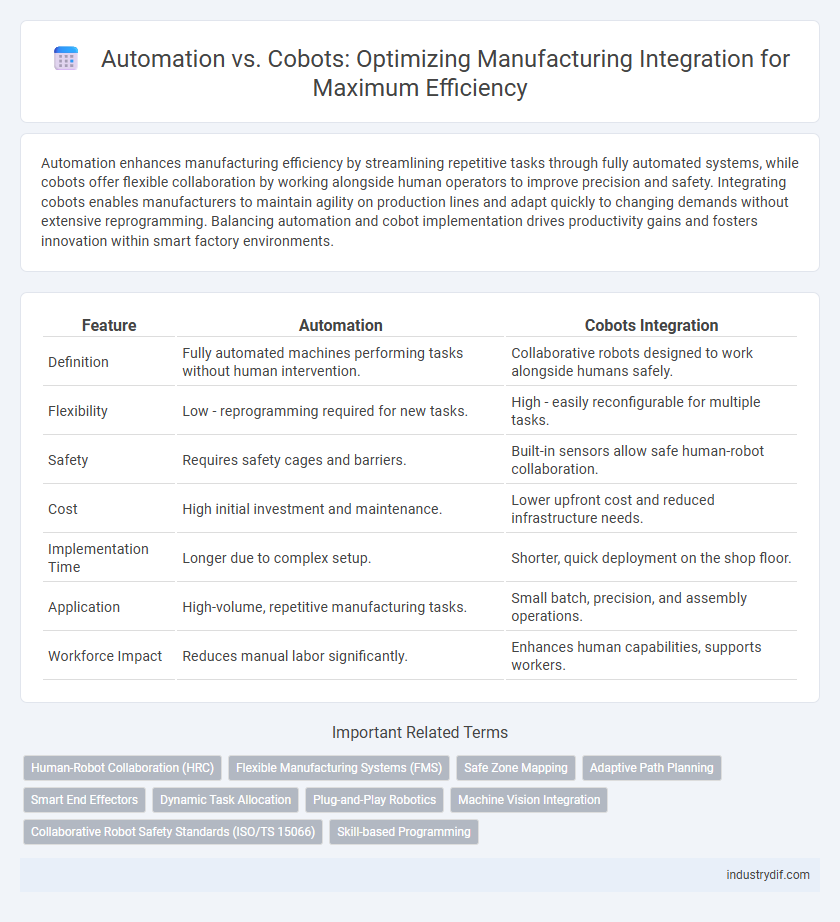

Table of Comparison

| Feature | Automation | Cobots Integration |

|---|---|---|

| Definition | Fully automated machines performing tasks without human intervention. | Collaborative robots designed to work alongside humans safely. |

| Flexibility | Low - reprogramming required for new tasks. | High - easily reconfigurable for multiple tasks. |

| Safety | Requires safety cages and barriers. | Built-in sensors allow safe human-robot collaboration. |

| Cost | High initial investment and maintenance. | Lower upfront cost and reduced infrastructure needs. |

| Implementation Time | Longer due to complex setup. | Shorter, quick deployment on the shop floor. |

| Application | High-volume, repetitive manufacturing tasks. | Small batch, precision, and assembly operations. |

| Workforce Impact | Reduces manual labor significantly. | Enhances human capabilities, supports workers. |

Overview of Automation and Cobots in Manufacturing

Automation in manufacturing encompasses the use of systems and machinery to perform tasks with minimal human intervention, increasing efficiency, consistency, and throughput across production lines. Collaborative robots (cobots) integrate seamlessly with human workers, offering flexibility and enhanced safety in complex assembly and quality control processes. The synergy of full automation and cobot deployment optimizes productivity while reducing operational costs and human error.

Key Differences Between Traditional Automation and Cobots

Traditional automation relies on fixed, pre-programmed machines designed for repetitive, high-volume tasks with minimal human intervention, offering consistency and speed. Cobots, or collaborative robots, are designed for flexible, adaptive interaction with human workers, enhancing task versatility and safety in mixed environments. Key differences include cobots' ability to learn and adjust to new tasks quickly, their integration in shared workspaces, and lower barriers to deployment compared to rigid traditional automation systems.

Benefits of Automation in Manufacturing Processes

Automation in manufacturing significantly enhances production efficiency by enabling continuous operation with minimal human intervention, reducing errors, and maintaining consistent quality standards. Advanced robotics and automated systems streamline complex tasks, improve throughput, and optimize resource utilization, leading to substantial cost savings. Integration of automation technologies supports scalable manufacturing, accelerates product delivery, and strengthens competitive advantage in the industry.

Advantages of Collaborative Robots (Cobots)

Collaborative robots (cobots) enhance manufacturing efficiency by working safely alongside human operators without extensive safety barriers, enabling flexible automation in small and medium-sized enterprises. Cobots improve precision and consistency while reducing labor costs and repetitive strain injuries, leading to higher productivity and worker satisfaction. Their easy programmability and adaptability allow seamless integration into existing workflows, accelerating deployment compared to traditional industrial robots.

Integration Challenges: Automation vs Cobots

Automation systems demand significant upfront investment and complex programming, often requiring specialized skills for integration with existing manufacturing processes. Cobots offer more flexible and intuitive deployment but pose challenges in ensuring safe human-robot collaboration and adapting to diverse tasks without compromising productivity. Both automation and cobots necessitate rigorous testing and continuous monitoring to address compatibility issues and optimize operational efficiency.

Cost Comparison: Automation Systems vs Cobots

Automation systems typically require higher initial capital investment due to complex machinery and extensive infrastructure modifications, whereas cobots offer lower upfront costs with flexible deployment in existing production lines. Operational expenses for automation systems include substantial maintenance and programming costs, while cobots are designed for easier reprogramming and lower maintenance needs, reducing ongoing expenditures. Total cost of ownership analysis often favors cobots in small to medium-sized production runs, but full automation systems may achieve cost advantages in high-volume manufacturing due to higher throughput and efficiency.

Flexibility and Scalability in Manufacturing Automation

Automation in manufacturing offers high scalability with consistent output, while cobots provide unmatched flexibility by working alongside human operators and adapting to varying tasks. Integrating cobots enhances production lines by enabling quick reconfiguration and seamless scaling without extensive downtime or capital investment. This combination optimizes workflow efficiency, supporting dynamic manufacturing environments and diverse product demands.

Safety Standards and Workplace Impacts

Automation systems and collaborative robots (cobots) significantly enhance manufacturing efficiency while differing in safety standards and workplace impacts. Automation typically requires rigorous safety barriers and isolation protocols to prevent human interaction risks, whereas cobots are designed with advanced sensors and force-limiting features to operate safely alongside human workers. Integrating cobots fosters improved ergonomic conditions and reduces repetitive strain injuries, promoting a more adaptable and inclusive work environment compared to traditional automation systems.

ROI: Evaluating Automation and Cobot Investments

Evaluating ROI in manufacturing necessitates a detailed comparison between full automation and collaborative robot (cobot) integration, focusing on initial capital expenditure, operational efficiency gains, and long-term maintenance costs. Automation typically promises higher throughput and consistency, while cobots offer flexibility and faster deployment with lower upfront costs, enhancing adaptability in mixed production environments. Quantifying productivity increases, error reduction rates, and energy savings is essential to determine the optimal investment strategy for maximizing manufacturing profitability.

Future Trends in Manufacturing: Automation and Cobots

Future trends in manufacturing emphasize seamless integration of advanced automation systems with collaborative robots (cobots) to enhance productivity and flexibility on the factory floor. Innovations in AI-driven automation and real-time data analytics enable cobots to work safely alongside human operators, optimizing complex tasks and reducing downtime. This convergence accelerates smart factory development, driving efficiency, precision, and scalability in Industry 4.0 environments.

Related Important Terms

Human-Robot Collaboration (HRC)

Human-Robot Collaboration (HRC) enhances manufacturing efficiency by combining automation's speed with cobots' adaptability to work safely alongside human operators. Integrating cobots into automated systems optimizes production workflows, reduces workplace injuries, and improves overall operational flexibility.

Flexible Manufacturing Systems (FMS)

Flexible Manufacturing Systems (FMS) achieve optimal efficiency by integrating automation and cobots, leveraging robots for repetitive tasks while using collaborative robots to adapt quickly to varying production needs. This hybrid approach enhances system flexibility, reduces downtime, and increases productivity by seamlessly combining precision automation with human-robot collaboration tailored to dynamic manufacturing environments.

Safe Zone Mapping

Safe zone mapping enhances automation by precisely defining hazardous areas to prevent collisions between robots and human workers. Integrating cobots with dynamic safe zone mapping increases operational safety and flexibility on manufacturing floors.

Adaptive Path Planning

Adaptive path planning in automation streamlines manufacturing processes by optimizing robotic trajectories to enhance precision and efficiency, significantly reducing cycle times and operational costs. Cobots integration leverages adaptive algorithms to dynamically adjust movements in real-time, improving collaboration safety and flexibility on the production floor while maintaining high throughput and minimizing downtime.

Smart End Effectors

Smart end effectors enhance automation by providing adaptable, sensor-equipped tools that improve precision and flexibility in manufacturing processes, enabling seamless integration with both traditional robots and collaborative robots (cobots). This synergy between automation and cobots maximizes operational efficiency, reduces human error, and accelerates production while maintaining high safety standards.

Dynamic Task Allocation

Dynamic task allocation in manufacturing optimizes workflow by assigning tasks between automation systems and collaborative robots (cobots) based on real-time data, enhancing productivity and flexibility. This integration allows cobots to handle complex, variable tasks while automation manages repetitive processes, resulting in improved efficiency and reduced downtime.

Plug-and-Play Robotics

Plug-and-play robotics streamline manufacturing by simplifying automation integration, allowing rapid deployment of automated systems without extensive programming or downtime. Cobots offer flexible collaboration alongside human workers, enhancing productivity with intuitive interfaces and adaptable tasks in contrast to fully automated machinery.

Machine Vision Integration

Machine vision integration enhances automation systems by providing precise real-time data for quality control, reducing errors, and increasing production speed. Cobots equipped with advanced machine vision adapt dynamically to changing environments, improving flexibility and collaborative efficiency in manufacturing processes.

Collaborative Robot Safety Standards (ISO/TS 15066)

Collaborative robot safety standards ISO/TS 15066 provide detailed guidelines for integrating automation and cobots in manufacturing environments, ensuring human-robot interaction risks are minimized through specific force, pressure, and speed limits. Compliance with ISO/TS 15066 enhances operational safety by defining permissible contact scenarios and enables manufacturers to leverage cobots' flexibility while maintaining rigorous safety protocols.

Skill-based Programming

Automation and cobots integration in manufacturing increasingly relies on skill-based programming, which enables operators to teach robots tasks through intuitive interfaces rather than traditional coding. This approach reduces setup time and enhances flexibility by allowing rapid adaptation to complex production processes and varying skill levels among workers.

Automation vs Cobots Integration Infographic

industrydif.com

industrydif.com