Process control systems regulate manufacturing operations through continuous monitoring and automated adjustments to maintain product quality and efficiency. Cyber-Physical Systems integrate computing, networking, and physical processes, enabling real-time data exchange and intelligent decision-making for enhanced flexibility and responsiveness. Combining process control with cyber-physical technologies drives smart manufacturing by optimizing performance and reducing downtime.

Table of Comparison

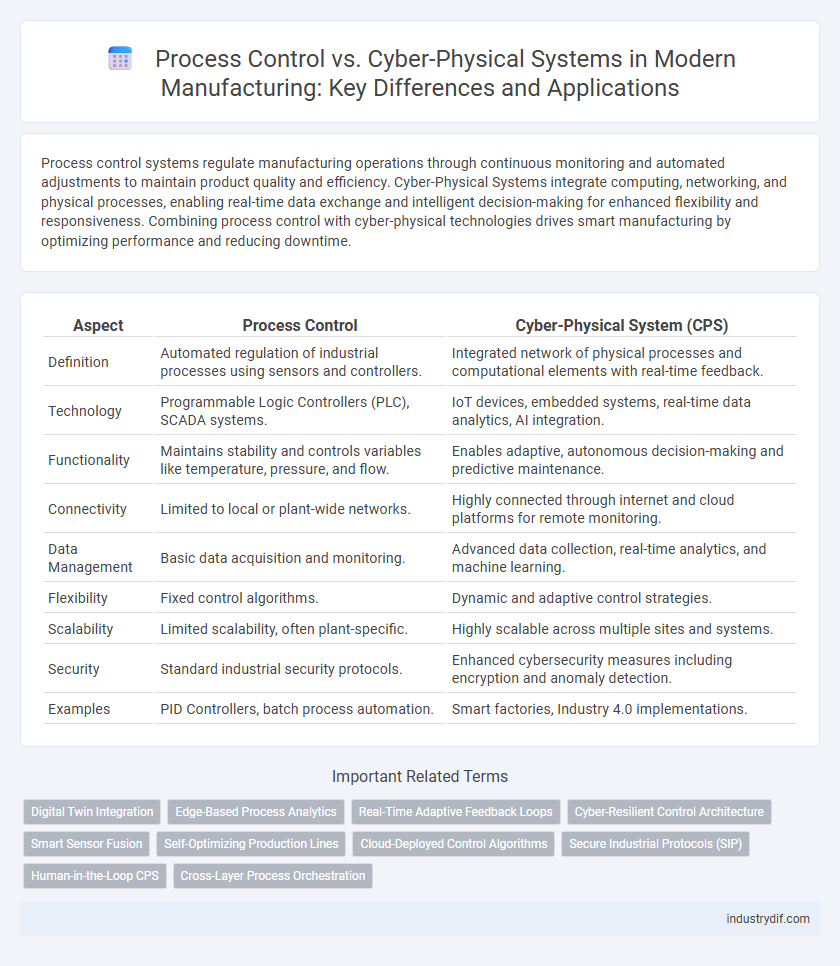

| Aspect | Process Control | Cyber-Physical System (CPS) |

|---|---|---|

| Definition | Automated regulation of industrial processes using sensors and controllers. | Integrated network of physical processes and computational elements with real-time feedback. |

| Technology | Programmable Logic Controllers (PLC), SCADA systems. | IoT devices, embedded systems, real-time data analytics, AI integration. |

| Functionality | Maintains stability and controls variables like temperature, pressure, and flow. | Enables adaptive, autonomous decision-making and predictive maintenance. |

| Connectivity | Limited to local or plant-wide networks. | Highly connected through internet and cloud platforms for remote monitoring. |

| Data Management | Basic data acquisition and monitoring. | Advanced data collection, real-time analytics, and machine learning. |

| Flexibility | Fixed control algorithms. | Dynamic and adaptive control strategies. |

| Scalability | Limited scalability, often plant-specific. | Highly scalable across multiple sites and systems. |

| Security | Standard industrial security protocols. | Enhanced cybersecurity measures including encryption and anomaly detection. |

| Examples | PID Controllers, batch process automation. | Smart factories, Industry 4.0 implementations. |

Defining Process Control in Manufacturing

Process control in manufacturing involves using sensors, controllers, and actuators to monitor and regulate production variables such as temperature, pressure, and flow rate, ensuring product quality and consistency. It relies on feedback loops and real-time data analysis to maintain stable operating conditions and reduce variability in processes like chemical production, assembly lines, and machining. This traditional control framework differs from cyber-physical systems by primarily focusing on process optimization rather than integrating extensive computational intelligence and network connectivity.

Understanding Cyber-Physical Systems (CPS)

Cyber-Physical Systems (CPS) integrate computation, networking, and physical processes to enhance manufacturing automation beyond traditional process control by enabling real-time data exchange and adaptive responses. Unlike conventional process control, CPS employs embedded systems and IoT sensors to monitor and optimize operations dynamically, increasing efficiency and reducing downtime. In manufacturing, CPS enables predictive maintenance, autonomous decision-making, and seamless interaction between digital and physical components, transforming smart factory capabilities.

Key Components of Process Control

Key components of process control include sensors for real-time data acquisition, controllers for decision-making based on input signals, and actuators to execute adjustments in manufacturing operations. These elements work together to maintain system stability, optimize production efficiency, and ensure product quality. Process control systems differ from cyber-physical systems by primarily focusing on automation within defined parameters rather than integrating computational algorithms with physical processes extensively.

Core Elements of Cyber-Physical Systems

Cyber-Physical Systems (CPS) in manufacturing integrate computation, networking, and physical processes through embedded sensors and actuators that enable real-time monitoring and control. Core elements of CPS include cybernetic components such as data analytics, communication networks, and physical elements like machinery and robotics, which work together to enhance automation and operational efficiency. Unlike traditional process control systems, CPS provides adaptive, interconnected, and intelligent environments essential for Industry 4.0 advancements.

Differences Between Process Control and CPS

Process control primarily involves monitoring and adjusting industrial processes using sensors and controllers to maintain desired output quality and efficiency. In contrast, Cyber-Physical Systems (CPS) integrate computation, networking, and physical processes, enabling real-time interaction and autonomous decision-making through interconnected devices and advanced data analytics. The key difference lies in CPS's capability for seamless integration of physical systems with cyber components, enhancing adaptability and predictive maintenance beyond traditional process control methods.

Integration of Process Control with CPS

Integration of process control with cyber-physical systems (CPS) enhances real-time monitoring and adaptive decision-making in manufacturing environments. CPS leverages IoT sensors and edge computing to enable predictive maintenance and optimize process parameters automatically, reducing downtime and increasing efficiency. This fusion drives smart factories through seamless communication between physical processes and computational algorithms.

Role of Automation in Process Control and CPS

Automation in process control relies on predefined algorithms and sensors to regulate manufacturing variables, ensuring consistent product quality and operational efficiency. Cyber-Physical Systems (CPS) integrate computational algorithms with physical processes, enabling real-time data exchange and adaptive decision-making across interconnected devices. The role of automation in CPS extends beyond traditional control by incorporating smart analytics and machine learning to optimize complex manufacturing workflows dynamically.

Benefits of Cyber-Physical Systems Over Traditional Process Control

Cyber-Physical Systems (CPS) enhance manufacturing efficiency by integrating real-time data analytics, sensor networks, and automated feedback loops, enabling adaptive and predictive control beyond traditional process control capabilities. CPS facilitates seamless communication between physical machinery and computational elements, resulting in improved fault detection, reduced downtime, and optimized resource utilization. Enhanced flexibility and scalability in CPS allow manufacturers to swiftly respond to dynamic production demands and implement complex process adjustments with minimal human intervention.

Industrial Applications: Process Control vs. CPS

Process Control systems in manufacturing rely on real-time monitoring and automation to maintain consistent production quality and efficiency through sensors and feedback loops. Cyber-Physical Systems (CPS) integrate computational algorithms with physical processes, enabling advanced data analytics, predictive maintenance, and adaptive control in industrial environments. Industrial applications of CPS enhance flexibility and scalability compared to traditional Process Control by connecting machines, humans, and data through the Industrial Internet of Things (IIoT) and smart manufacturing frameworks.

Future Trends in Manufacturing: Convergence of Process Control and CPS

Future trends in manufacturing highlight the convergence of traditional process control systems with advanced cyber-physical systems (CPS), enabling real-time data integration, predictive analytics, and autonomous decision-making. This integration enhances operational efficiency, promotes adaptive manufacturing environments, and supports Industry 4.0 initiatives through seamless connectivity between physical processes and digital technologies. The fusion of process control and CPS drives innovation in smart factories, facilitating enhanced precision, flexibility, and resilience in production workflows.

Related Important Terms

Digital Twin Integration

Process control systems manage manufacturing operations through real-time monitoring and automation, while cyber-physical systems (CPS) integrate physical processes with computational models for enhanced coordination. Digital twin integration within CPS enables precise simulation and predictive maintenance, optimizing production efficiency and reducing downtime.

Edge-Based Process Analytics

Edge-based process analytics in manufacturing leverages real-time data processing at the network edge, enabling more accurate and timely decision-making compared to traditional process control systems that rely on centralized analysis. Cyber-physical systems integrate physical manufacturing processes with digital analytics on the edge, enhancing responsiveness and predictive maintenance through seamless machine-to-machine communication and localized data computation.

Real-Time Adaptive Feedback Loops

Process control in manufacturing relies on fixed algorithms and predefined thresholds to maintain system stability, whereas cyber-physical systems integrate real-time adaptive feedback loops using sensor data and machine learning to dynamically optimize production processes. These advanced cyber-physical feedback mechanisms enhance responsiveness and efficiency, allowing for immediate adjustments to changing conditions and reducing downtime.

Cyber-Resilient Control Architecture

Cyber-resilient control architecture integrates advanced cyber-physical systems with robust security protocols to protect manufacturing process control from cyber threats and ensure continuous operational stability. Leveraging real-time monitoring, fault detection, and adaptive response mechanisms, it enhances system reliability and minimizes downtime in smart manufacturing environments.

Smart Sensor Fusion

Smart sensor fusion in manufacturing enhances process control by integrating real-time data from multiple sensors, improving accuracy and responsiveness. Cyber-physical systems leverage this fusion to enable adaptive, self-optimizing production environments that reduce downtime and increase efficiency.

Self-Optimizing Production Lines

Self-optimizing production lines leverage cyber-physical systems (CPS) that integrate real-time data analytics and machine learning algorithms to enhance process control by autonomously adjusting parameters for optimal performance. Unlike traditional process control, CPS enables dynamic adaptation to variations in manufacturing environments, resulting in increased efficiency, reduced downtime, and improved product quality.

Cloud-Deployed Control Algorithms

Cloud-deployed control algorithms enhance process control by enabling real-time data processing and adaptive optimization across distributed manufacturing systems, which surpasses traditional cyber-physical systems limited by localized computation. This integration improves scalability, fault tolerance, and predictive maintenance, driving higher operational efficiency and reduced downtime in modern industrial manufacturing environments.

Secure Industrial Protocols (SIP)

Process Control relies on traditional automation frameworks with limited integration of Secure Industrial Protocols (SIP), often exposing manufacturing networks to vulnerabilities; Cyber-Physical Systems (CPS) incorporate advanced SIP standards that enhance real-time data integrity, encryption, and authentication, ensuring robust security across interconnected industrial devices. Implementing SIP within CPS enables dynamic monitoring and adaptive defense mechanisms, crucial for protecting manufacturing operations against cyber threats and unauthorized access.

Human-in-the-Loop CPS

Process control in manufacturing relies on automated systems to regulate variables and maintain product consistency, while Cyber-Physical Systems (CPS) integrate computational algorithms with physical processes to enable real-time monitoring and adaptive decision-making. Human-in-the-Loop CPS enhances this integration by incorporating human judgment and expertise directly into the control loop, improving system flexibility, fault detection, and operational resilience in complex manufacturing environments.

Cross-Layer Process Orchestration

Cross-layer process orchestration in manufacturing integrates process control and cyber-physical systems to enhance real-time monitoring, adaptive decision-making, and seamless coordination across physical and digital layers. This approach leverages sensors, actuators, and embedded software to optimize production efficiency, reduce downtime, and enable predictive maintenance within smart factory environments.

Process Control vs Cyber-Physical System Infographic

industrydif.com

industrydif.com