Just-in-Time (JIT) manufacturing reduces inventory waste by synchronizing production schedules with actual demand, ensuring materials arrive precisely when needed. Demand-Driven Material Requirements Planning (DDMRP) enhances traditional MRP by incorporating real-time demand signals and buffer management to optimize inventory levels and flow. Both strategies aim to improve supply chain efficiency, but JIT emphasizes timing, while DDMRP focuses on demand variability and dynamic adjustments.

Table of Comparison

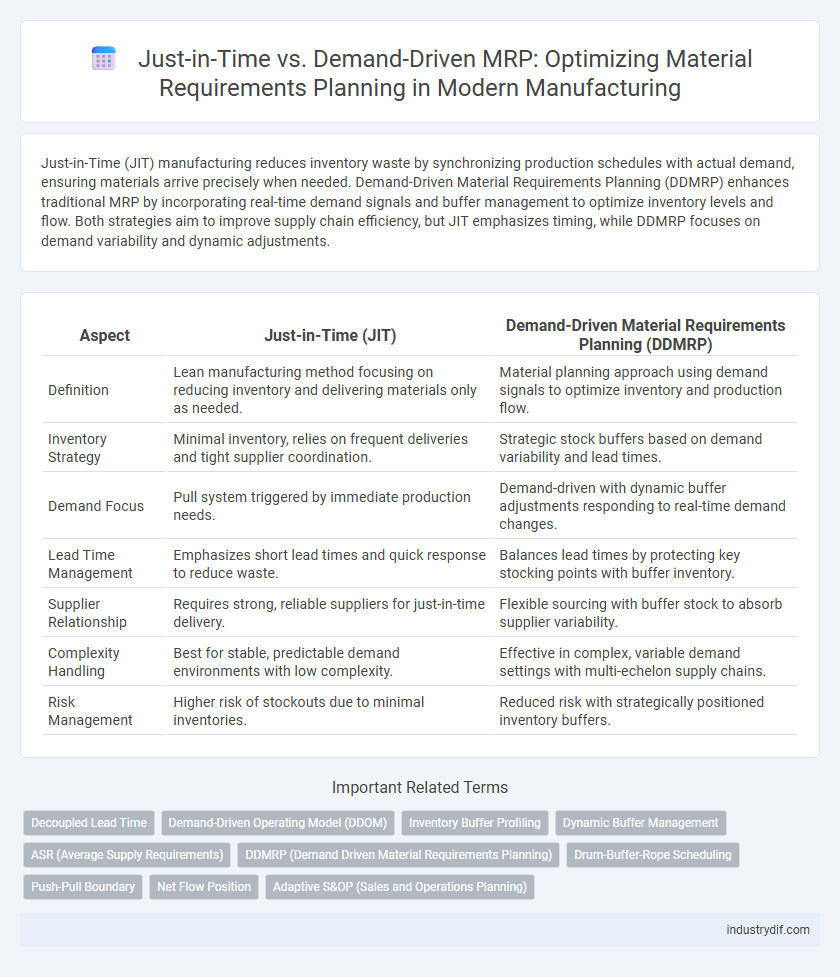

| Aspect | Just-in-Time (JIT) | Demand-Driven Material Requirements Planning (DDMRP) |

|---|---|---|

| Definition | Lean manufacturing method focusing on reducing inventory and delivering materials only as needed. | Material planning approach using demand signals to optimize inventory and production flow. |

| Inventory Strategy | Minimal inventory, relies on frequent deliveries and tight supplier coordination. | Strategic stock buffers based on demand variability and lead times. |

| Demand Focus | Pull system triggered by immediate production needs. | Demand-driven with dynamic buffer adjustments responding to real-time demand changes. |

| Lead Time Management | Emphasizes short lead times and quick response to reduce waste. | Balances lead times by protecting key stocking points with buffer inventory. |

| Supplier Relationship | Requires strong, reliable suppliers for just-in-time delivery. | Flexible sourcing with buffer stock to absorb supplier variability. |

| Complexity Handling | Best for stable, predictable demand environments with low complexity. | Effective in complex, variable demand settings with multi-echelon supply chains. |

| Risk Management | Higher risk of stockouts due to minimal inventories. | Reduced risk with strategically positioned inventory buffers. |

Introduction to Just-in-Time and Demand-Driven MRP

Just-in-Time (JIT) manufacturing minimizes inventory levels by producing goods only as needed, reducing waste and improving efficiency. Demand-Driven Material Requirements Planning (DDMRP) integrates real-time demand signals to optimize inventory and production scheduling, enhancing responsiveness to market changes. Both methodologies focus on aligning production closely with customer demand to improve supply chain agility and reduce operational costs.

Core Principles of Just-in-Time Manufacturing

Just-in-Time (JIT) manufacturing centers on eliminating waste by producing only what is needed, when it is needed, and in the exact quantity required, optimizing inventory levels. Core principles include continuous workflow, pull systems driven by customer demand, and supplier integration to ensure timely material delivery. This approach contrasts with Demand-Driven Material Requirements Planning (DDMRP), which relies heavily on buffer stocks and dynamic demand signals to adjust production schedules and inventory.

Fundamentals of Demand-Driven Material Requirements Planning

Demand-Driven Material Requirements Planning (DDMRP) integrates real-time demand signals and inventory buffers to optimize supply chain responsiveness and reduce lead times. It focuses on managing stock levels dynamically using strategically positioned decoupling points to absorb variability and prevent disruptions. This approach contrasts with traditional Just-in-Time (JIT) methods by emphasizing demand variability and promoting flexibility over strict synchronization with production schedules.

Key Differences Between JIT and DD MRP Approaches

Just-in-Time (JIT) focuses on minimizing inventory by synchronizing production schedules with actual demand, reducing waste and lead times. Demand-Driven Material Requirements Planning (DDMRP) integrates real-time demand signals with buffer management to optimize inventory levels and improve supply chain responsiveness. JIT relies heavily on efficient workflows and supplier reliability, while DDMRP emphasizes dynamic adjustments to inventory buffers based on demand variability and supply constraints.

Inventory Management Strategies: JIT vs Demand-Driven MRP

Just-in-Time (JIT) prioritizes minimizing inventory levels by aligning production schedules closely with demand, reducing carrying costs and waste. Demand-Driven Material Requirements Planning (DDMRP) incorporates real-time demand signals and strategic inventory buffers to optimize stock levels, enhancing responsiveness to market fluctuations. Both strategies focus on inventory reduction but differ in adaptability, with DDMRP offering greater flexibility for variable demand.

Impact on Supply Chain Agility and Responsiveness

Just-in-Time (JIT) emphasizes reducing inventory levels by synchronizing production with demand, enhancing supply chain agility through minimized lead times but risks disruptions from demand variability. Demand-Driven Material Requirements Planning (DDMRP) integrates strategic stock buffers and real-time data to improve responsiveness and buffer variability, enabling more adaptive and resilient supply chain operations. DDMRP's focus on demand signals and dynamic adjustments often results in superior supply chain responsiveness compared to traditional JIT systems.

Technology Integration in JIT and DD MRP Systems

Just-in-Time (JIT) systems leverage real-time data analytics and IoT sensors to minimize inventory levels by synchronizing production schedules with supplier deliveries, thereby reducing waste and enhancing efficiency. Demand-Driven Material Requirements Planning (DD MRP) incorporates advanced AI algorithms and cloud-based platforms to dynamically adjust procurement and production schedules based on actual market demand signals. Both JIT and DD MRP rely heavily on integrated ERP systems and automated communication networks to optimize supply chain responsiveness and maintain seamless material flow.

Risk Mitigation and Operational Flexibility

Just-in-Time (JIT) manufacturing minimizes inventory risks by synchronizing production schedules tightly with demand, reducing waste and storage costs but increasing vulnerability to supply chain disruptions. Demand-Driven Material Requirements Planning (DDMRP) enhances operational flexibility by using dynamic buffers that adjust inventory levels based on real-time demand signals, providing a more resilient response to variability. Integrating DDMRP offers superior risk mitigation by balancing inventory optimization with responsiveness, helping manufacturers maintain continuous production flow despite uncertainties.

Cost Efficiency and Waste Reduction Comparison

Just-in-Time (JIT) manufacturing minimizes inventory holding costs and reduces waste by synchronizing production with demand, leading to lean operations and lower capital expenditures. Demand-Driven Material Requirements Planning (DDMRP) enhances cost efficiency by dynamically adjusting inventory buffers based on actual market signals, preventing stockouts and excess inventory. Both methodologies drive waste reduction, but DDMRP offers improved responsiveness and optimized resource allocation for fluctuating demand environments.

Choosing the Right Material Planning Method for Your Manufacturing Needs

Just-in-Time (JIT) emphasizes minimizing inventory by aligning production schedules closely with actual demand, reducing waste and storage costs. Demand-Driven Material Requirements Planning (DDMRP) integrates real-time demand signals and inventory buffers to enhance supply chain responsiveness and flexibility. Selecting the appropriate material planning method depends on factors such as production volume variability, lead time reliability, and the complexity of supply chains.

Related Important Terms

Decoupled Lead Time

Decoupled Lead Time in Just-in-Time (JIT) manufacturing minimizes inventory by synchronizing production closely with demand, reducing delays and waste. In contrast, Demand-Driven Material Requirements Planning (DDMRP) leverages strategic inventory buffers to protect decoupled lead times, enhancing supply chain resilience and responsiveness to demand variability.

Demand-Driven Operating Model (DDOM)

The Demand-Driven Operating Model (DDOM) enhances manufacturing agility by synchronizing production schedules with actual customer demand through real-time data integration and buffer management, reducing inventory costs and lead times compared to traditional Just-in-Time systems. DDOM leverages demand-driven material requirements planning (DDMRP) principles, optimizing supply chain responsiveness and minimizing disruptions by dynamically adjusting parameters based on market fluctuations and consumption patterns.

Inventory Buffer Profiling

Just-in-Time (JIT) manufacturing minimizes inventory buffers by aligning production schedules closely with demand, reducing carrying costs and waste. Demand-Driven Material Requirements Planning (DDMRP) uses strategic inventory buffer profiling based on real-time demand variability and lead times, enhancing supply chain resilience and improving service levels.

Dynamic Buffer Management

Dynamic Buffer Management in Demand-Driven Material Requirements Planning optimizes inventory by continuously adjusting buffer levels based on real-time demand signals and variability, reducing excess stock and minimizing shortages. Just-in-Time systems rely on strict scheduling and minimal inventory, but lack the adaptive flexibility of dynamic buffers to respond promptly to demand fluctuations in complex manufacturing environments.

ASR (Average Supply Requirements)

Just-in-Time (JIT) manufacturing minimizes inventory by synchronizing production schedules closely with actual demand, whereas Demand-Driven Material Requirements Planning (DDMRP) uses dynamic buffers based on Average Supply Requirements (ASR) to optimize stock levels and reduce supply chain variability. ASR in DDMRP ensures materials are replenished in alignment with real-time consumption rates, enhancing responsiveness and minimizing stockouts compared to the rigid timing of JIT systems.

DDMRP (Demand Driven Material Requirements Planning)

Demand Driven Material Requirements Planning (DDMRP) enhances manufacturing efficiency by dynamically adjusting inventory and production schedules based on real-time demand signals, reducing lead times and minimizing excess stock. Unlike traditional Just-in-Time (JIT) systems that focus on synchronized deliveries, DDMRP integrates buffer management and demand variability to improve supply chain resilience and responsiveness.

Drum-Buffer-Rope Scheduling

Drum-Buffer-Rope scheduling in Demand-Driven Material Requirements Planning (DDMRP) enhances manufacturing flow by controlling inventory buffers and synchronizing production with actual demand, contrasting with Just-in-Time's reliance on precise timing and minimal inventory. This approach minimizes bottlenecks and lead times through strategically placed buffers and dynamic scheduling, optimizing throughput and responsiveness in complex manufacturing environments.

Push-Pull Boundary

The push-pull boundary in manufacturing delineates the point where production shifts from forecast-driven push processes to actual demand-driven pull processes, optimizing inventory levels and reducing lead times. Just-in-Time (JIT) systems operate primarily on the pull side by synchronizing production with real-time demand, while Demand-Driven Material Requirements Planning (DDMRP) strategically positions the push-pull boundary to balance responsiveness and efficiency across the supply chain.

Net Flow Position

Net Flow Position (NFP) in Just-in-Time (JIT) manufacturing prioritizes inventory minimization by aligning production closely with consumption, reducing holding costs and waste. In contrast, Demand-Driven Material Requirements Planning (DDMRP) leverages NFP to balance inventory buffers dynamically, enhancing responsiveness to demand variability and improving supply chain resilience.

Adaptive S&OP (Sales and Operations Planning)

Just-in-Time (JIT) focuses on minimizing inventory by synchronizing production closely with demand, whereas Demand-Driven Material Requirements Planning (DDMRP) incorporates real-time demand signals to dynamically adjust inventory buffers and production schedules. Adaptive Sales and Operations Planning (S&OP) leverages DDMRP's responsiveness to improve forecast accuracy and agility, enabling manufacturers to better align supply with fluctuating customer demand.

Just-in-Time vs Demand-Driven Material Requirements Planning Infographic

industrydif.com

industrydif.com