Batch production enables manufacturers to produce goods in specific quantities, optimizing resource use and reducing costs for standardized products. On-demand manufacturing offers flexibility by producing items only when orders are received, minimizing inventory and allowing customization. Choosing between these methods depends on production scale, product variety, and market demand sensitivity.

Table of Comparison

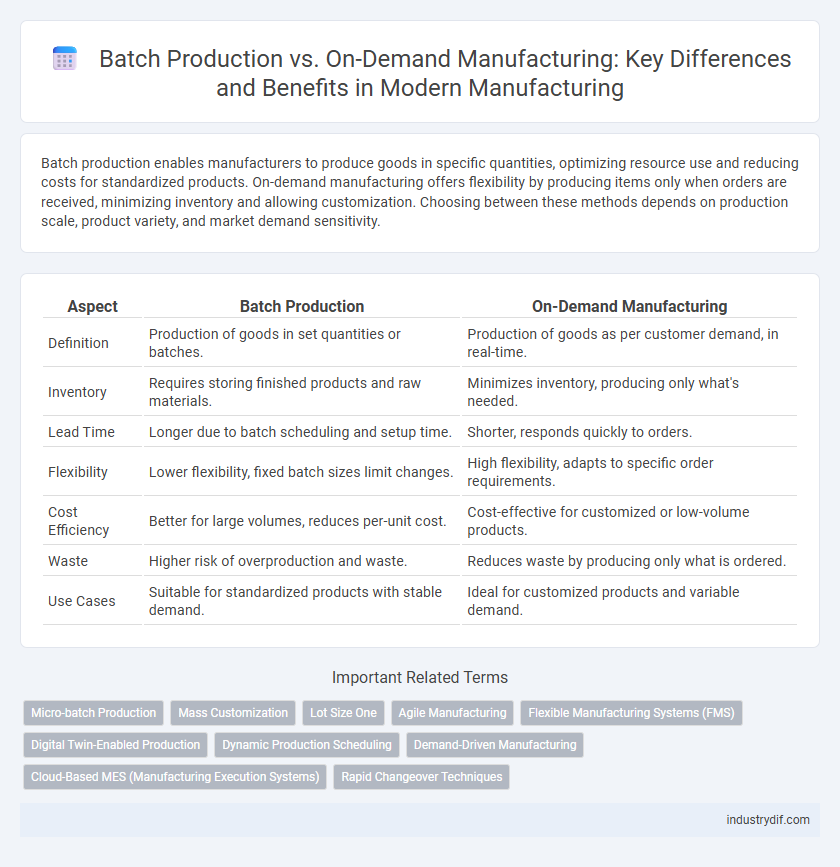

| Aspect | Batch Production | On-Demand Manufacturing |

|---|---|---|

| Definition | Production of goods in set quantities or batches. | Production of goods as per customer demand, in real-time. |

| Inventory | Requires storing finished products and raw materials. | Minimizes inventory, producing only what's needed. |

| Lead Time | Longer due to batch scheduling and setup time. | Shorter, responds quickly to orders. |

| Flexibility | Lower flexibility, fixed batch sizes limit changes. | High flexibility, adapts to specific order requirements. |

| Cost Efficiency | Better for large volumes, reduces per-unit cost. | Cost-effective for customized or low-volume products. |

| Waste | Higher risk of overproduction and waste. | Reduces waste by producing only what is ordered. |

| Use Cases | Suitable for standardized products with stable demand. | Ideal for customized products and variable demand. |

Understanding Batch Production in Manufacturing

Batch production involves manufacturing a specific quantity of products in groups or batches, allowing for efficient use of resources and consistent quality control. This method is ideal for producing items with similar specifications, minimizing setup times and reducing production costs. Understanding batch production helps manufacturers optimize workflows, balance inventory levels, and respond flexibly to market demand variations.

What is On-Demand Manufacturing?

On-demand manufacturing is a production process where products are created only after receiving a customer order, minimizing inventory and reducing waste. This method leverages flexible manufacturing technologies and real-time data to quickly respond to market demands and customization requests. It contrasts with batch production by emphasizing efficiency, cost-effectiveness, and agility in fulfilling individual customer needs.

Key Differences Between Batch and On-Demand Production

Batch production involves manufacturing products in fixed quantities, allowing economies of scale and standardized quality control, whereas on-demand manufacturing produces items only as orders are received, reducing inventory costs and enabling greater customization. Batch production suits industries with predictable demand and longer product lifecycles, while on-demand manufacturing aligns with rapidly changing market trends and personalized customer requirements. Lead times in batch production are generally longer due to setup and processing phases, whereas on-demand manufacturing offers faster turnaround by minimizing waiting periods between order and production.

Benefits of Batch Production for Manufacturers

Batch production offers manufacturers greater efficiency through the mass processing of items with similar specifications, significantly reducing setup and downtime costs. It enables consistent quality control, as products within a batch maintain uniform standards due to standardized processes. Inventory management improves with batch manufacturing by allowing companies to stockpile finished goods, ensuring faster fulfillment and mitigating supply chain disruptions.

Advantages of On-Demand Manufacturing

On-demand manufacturing reduces inventory costs by producing goods only when orders are received, enhancing cash flow management. It allows increased flexibility and customization, meeting specific customer requirements without overproduction. This method also minimizes waste and supports faster turnaround times, improving overall operational efficiency in manufacturing processes.

Cost Implications: Batch vs On-Demand

Batch production often leads to lower per-unit costs due to economies of scale, making it cost-effective for large volume orders but risks higher inventory holding costs. On-demand manufacturing minimizes inventory expenses by producing only what is needed, but typically incurs higher per-unit costs due to smaller production runs and frequent setup changes. Evaluating cost implications requires balancing upfront tooling and storage expenses against the flexibility and responsiveness to market demand fluctuations.

Inventory Management Strategies

Batch production enables efficient inventory management by producing goods in fixed quantities, reducing storage costs through bulk procurement and standardized workflows. On-demand manufacturing minimizes inventory holding by producing products only as orders are received, lowering risks of excess stock and obsolescence. Choosing between batch production and on-demand manufacturing depends on factors such as demand variability, lead times, and capital investment in inventory systems.

Lead Time and Flexibility Comparison

Batch production typically involves longer lead times due to the setup and processing of large quantities, making it less adaptable to sudden changes in demand. On-demand manufacturing offers significantly shorter lead times by producing items only as orders are received, increasing flexibility and reducing inventory costs. This approach enables manufacturers to quickly respond to market fluctuations and customize products without the delays associated with batch processing.

Quality Control in Batch vs On-Demand Processes

Quality control in batch production involves rigorous testing of a sample from each batch to ensure consistency across large quantities, leveraging standardized procedures that detect defects before mass distribution. On-demand manufacturing emphasizes real-time quality checks on individual items, minimizing waste and allowing rapid adjustments for customization or changing specifications. Both approaches prioritize defect prevention, but batch production benefits from economies of scale while on-demand manufacturing excels in flexibility and responsiveness to market demands.

Choosing the Right Production Method for Your Business

Batch production maximizes efficiency and reduces costs by producing goods in large quantities, ideal for businesses with stable demand and standardized products. On-demand manufacturing offers flexibility and minimizes inventory expenses, making it suitable for customized orders and fluctuating market needs. Evaluating factors such as product complexity, order volume, and lead time aids in selecting the optimal production method to enhance profitability and customer satisfaction.

Related Important Terms

Micro-batch Production

Micro-batch production combines the benefits of batch production and on-demand manufacturing by producing small quantities of customized products that reduce inventory costs and minimize waste. This approach enhances flexibility and responsiveness in manufacturing processes, making it ideal for industries requiring frequent product variations or rapid prototyping.

Mass Customization

Batch production enables efficient manufacturing of large quantities with consistent quality, while on-demand manufacturing offers flexibility for customized orders without excess inventory. Mass customization merges these approaches by using scalable batch processes integrated with real-time data and automation to deliver personalized products rapidly and cost-effectively.

Lot Size One

Batch production involves manufacturing goods in predetermined quantities, optimizing efficiency for larger lot sizes, while on-demand manufacturing or Lot Size One focuses on producing customized products individually, minimizing inventory and reducing waste through flexible, tailored processes. Emphasizing Lot Size One in on-demand manufacturing enables businesses to meet specific customer requirements quickly, enhancing responsiveness and reducing lead times in highly competitive markets.

Agile Manufacturing

Batch production offers predictable output and cost efficiency through standardized processes, whereas on-demand manufacturing enhances flexibility by producing only what is required, reducing inventory and waste. Agile manufacturing integrates these approaches by leveraging real-time data and adaptive workflows to swiftly respond to market changes and customize products effectively.

Flexible Manufacturing Systems (FMS)

Flexible Manufacturing Systems (FMS) enhance batch production by allowing rapid switching between different product batches without significant downtime, optimizing resource utilization and reducing lead times. In on-demand manufacturing, FMS supports customization and small production runs by adapting workflows and machinery dynamically, enabling efficient response to fluctuating customer demand.

Digital Twin-Enabled Production

Digital twin-enabled production enhances batch production by creating virtual replicas of manufacturing processes, enabling real-time monitoring, predictive maintenance, and quality control that reduce downtime and waste. In on-demand manufacturing, digital twins facilitate rapid customization and agile response to market demands by simulating production scenarios, optimizing resource allocation, and accelerating product delivery cycles.

Dynamic Production Scheduling

Dynamic production scheduling in batch production optimizes resource allocation by grouping similar items into fixed-volume lots, reducing setup times and inventory costs. In contrast, on-demand manufacturing leverages real-time scheduling adjustments to respond swiftly to individual customer orders, minimizing lead times and enhancing production flexibility.

Demand-Driven Manufacturing

Demand-driven manufacturing adapts production schedules based on real-time customer orders, significantly reducing inventory costs and minimizing waste compared to traditional batch production methods. This approach leverages advanced analytics and IoT technologies to synchronize supply chains and enhance responsiveness to market fluctuations.

Cloud-Based MES (Manufacturing Execution Systems)

Cloud-based MES platforms optimize batch production by providing real-time tracking, inventory control, and quality management, enabling manufacturers to scale efficiently while minimizing downtime. In on-demand manufacturing, these systems enhance flexibility and responsiveness by integrating order data with production workflows, facilitating just-in-time resource allocation and rapid adjustments to changing demand.

Rapid Changeover Techniques

Rapid changeover techniques in batch production significantly reduce downtime by streamlining equipment adjustments and setup processes, enhancing efficiency for medium to large volume manufacturing runs. In contrast, on-demand manufacturing leverages flexible changeover methods to swiftly switch between customized orders, optimizing responsiveness and minimizing inventory costs.

Batch Production vs On-Demand Manufacturing Infographic

industrydif.com

industrydif.com