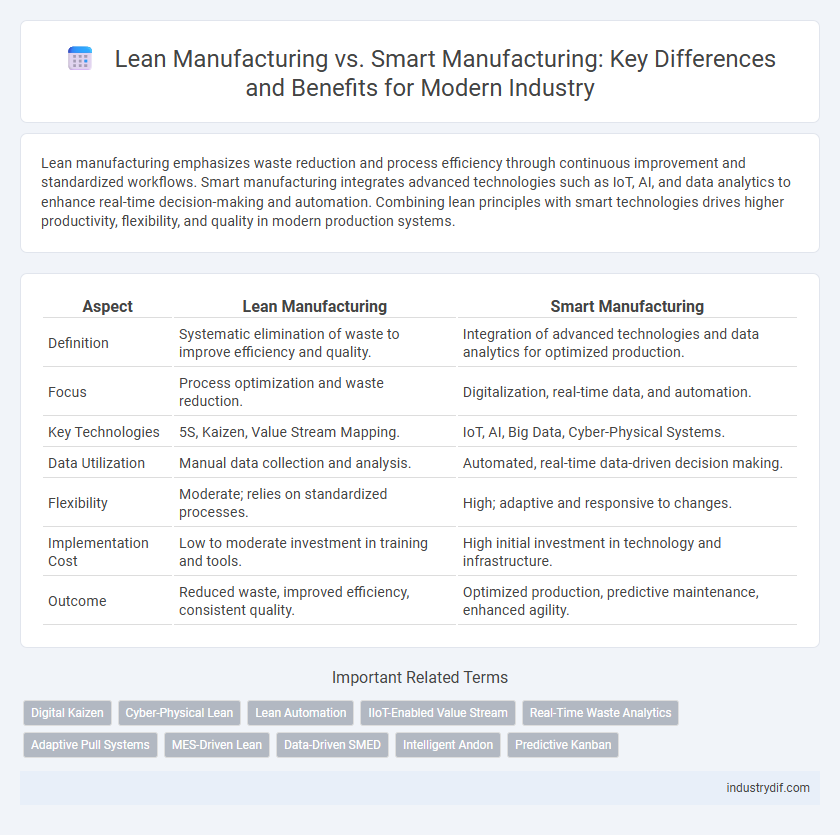

Lean manufacturing emphasizes waste reduction and process efficiency through continuous improvement and standardized workflows. Smart manufacturing integrates advanced technologies such as IoT, AI, and data analytics to enhance real-time decision-making and automation. Combining lean principles with smart technologies drives higher productivity, flexibility, and quality in modern production systems.

Table of Comparison

| Aspect | Lean Manufacturing | Smart Manufacturing |

|---|---|---|

| Definition | Systematic elimination of waste to improve efficiency and quality. | Integration of advanced technologies and data analytics for optimized production. |

| Focus | Process optimization and waste reduction. | Digitalization, real-time data, and automation. |

| Key Technologies | 5S, Kaizen, Value Stream Mapping. | IoT, AI, Big Data, Cyber-Physical Systems. |

| Data Utilization | Manual data collection and analysis. | Automated, real-time data-driven decision making. |

| Flexibility | Moderate; relies on standardized processes. | High; adaptive and responsive to changes. |

| Implementation Cost | Low to moderate investment in training and tools. | High initial investment in technology and infrastructure. |

| Outcome | Reduced waste, improved efficiency, consistent quality. | Optimized production, predictive maintenance, enhanced agility. |

Introduction to Lean and Smart Manufacturing

Lean manufacturing emphasizes waste reduction and process efficiency by streamlining workflows and minimizing non-value-added activities. Smart manufacturing integrates advanced technologies such as IoT, AI, and data analytics to enhance real-time decision-making and automation capabilities. Combining lean principles with smart innovations drives operational excellence and improves productivity in modern manufacturing environments.

Core Principles of Lean Manufacturing

Lean Manufacturing centers on eliminating waste, optimizing workflows, and continuous improvement to enhance efficiency and reduce costs in production processes. Core principles include value stream mapping to identify non-value-adding activities, just-in-time inventory to minimize excess stock, and empowering employees through standardized work practices. These methodologies drive operational excellence by streamlining resources and improving quality without relying heavily on advanced technologies like Smart Manufacturing.

Key Components of Smart Manufacturing

Smart Manufacturing integrates advanced technologies such as IoT sensors, real-time data analytics, and AI-driven automation to enhance production efficiency and flexibility. Unlike Lean Manufacturing, which emphasizes waste reduction and process optimization, Smart Manufacturing focuses on interconnected systems that enable predictive maintenance and intelligent decision-making. Key components include cyber-physical systems, cloud computing, and digital twin technology that facilitate seamless communication and adaptive control across the manufacturing lifecycle.

Comparative Goals: Efficiency vs. Connectivity

Lean Manufacturing prioritizes efficiency by minimizing waste and optimizing processes to reduce costs and improve production speed. Smart Manufacturing emphasizes connectivity through the integration of IoT devices and real-time data analytics, enabling adaptive decision-making and enhanced system responsiveness. Both approaches aim to enhance productivity, but Lean Manufacturing focuses on process streamlining while Smart Manufacturing targets intelligent, connected operations.

Technology Adoption in Manufacturing

Lean Manufacturing emphasizes waste reduction and process efficiency through standardized workflows, while Smart Manufacturing integrates advanced technologies such as IoT, AI, and robotics to enable real-time data analytics and adaptive control systems. Technology adoption in Smart Manufacturing drives predictive maintenance, automated quality control, and enhanced supply chain visibility, surpassing traditional lean methods that rely on manual monitoring and continuous improvement cycles. Manufacturers leveraging digital twins, cloud computing, and machine learning gain competitive advantages by optimizing operational agility and reducing downtime.

Role of Data and Analytics

Lean Manufacturing emphasizes waste reduction through standardized processes and continuous improvement, relying on basic data collection for operational efficiency. Smart Manufacturing integrates advanced data analytics, IoT sensors, and real-time monitoring to optimize production with predictive maintenance and adaptive control systems. The role of data shifts from retrospective analysis to proactive decision-making, enabling agile responses and enhanced productivity across the manufacturing value chain.

Workforce and Skill Requirements

Lean Manufacturing emphasizes workforce efficiency through standardized tasks and continuous improvement, requiring skills in process optimization and problem-solving. Smart Manufacturing demands advanced digital literacy, data analysis capabilities, and proficiency in automation technologies to manage interconnected systems. The evolving skill requirements reflect a shift from manual expertise to a hybrid of technical and analytical competencies in modern manufacturing environments.

Cost Implications and Returns

Lean manufacturing reduces costs by minimizing waste and optimizing resource use, leading to immediate savings in materials and labor. Smart manufacturing leverages IoT, AI, and automation to enhance production efficiency and predictive maintenance, resulting in higher upfront investment but greater long-term returns through reduced downtime and improved product quality. The integration of smart technologies can amplify lean principles, driving substantial cost reductions and accelerated ROI in complex manufacturing environments.

Integration with Industry 4.0

Lean Manufacturing emphasizes waste reduction and process efficiency through continuous improvement, while Smart Manufacturing leverages Industry 4.0 technologies like IoT, AI, and cyber-physical systems to enable real-time data integration and autonomous decision-making. The integration with Industry 4.0 allows Smart Manufacturing to enhance predictive maintenance, supply chain optimization, and adaptive production processes beyond traditional lean principles. Combining Lean Manufacturing's efficiency focus with Smart Manufacturing's digital connectivity creates a more responsive and agile manufacturing environment.

Future Trends in Manufacturing Practices

Lean manufacturing emphasizes waste reduction and efficiency through standardized processes, while smart manufacturing integrates advanced technologies such as IoT, AI, and big data analytics to enable real-time decision-making and predictive maintenance. Future trends indicate a shift towards hybrid models that combine lean principles with smart technologies to enhance agility, reduce downtime, and optimize resource utilization. Embracing digital twins and cyber-physical systems will further transform production lines, driving innovation and sustainability in manufacturing practices.

Related Important Terms

Digital Kaizen

Digital Kaizen in Lean Manufacturing emphasizes continuous incremental improvements through digital tools that enhance efficiency and reduce waste. Smart Manufacturing integrates Digital Kaizen to leverage real-time data analytics and automation, driving adaptive, intelligent production processes with minimized downtime.

Cyber-Physical Lean

Cyber-Physical Lean manufacturing integrates Lean principles with advanced IoT, robotics, and real-time data analytics to enhance flexibility, reduce waste, and optimize production processes. This fusion of Cyber-Physical Systems with Lean methodologies accelerates decision-making and drives continuous improvement in smart factories.

Lean Automation

Lean automation integrates lean manufacturing principles with advanced automation technologies to eliminate waste, optimize workflows, and enhance production efficiency in manufacturing environments. This approach leverages real-time data, robotics, and IoT to streamline operations while maintaining continuous improvement and cost reduction goals inherent in traditional lean manufacturing.

IIoT-Enabled Value Stream

Lean Manufacturing emphasizes eliminating waste and optimizing workflow efficiency through continuous improvement, while Smart Manufacturing leverages IIoT-enabled value streams to integrate real-time data analytics, predictive maintenance, and automated decision-making across the production lifecycle. IIoT devices enhance visibility and connectivity, enabling dynamic adjustments that reduce downtime and increase throughput within smart factories.

Real-Time Waste Analytics

Lean Manufacturing emphasizes minimizing waste through standardized processes and continuous improvement, relying heavily on historical data and manual observations. Smart Manufacturing integrates real-time waste analytics using IoT sensors and AI-driven platforms to detect inefficiencies instantly, enabling dynamic adjustments that significantly enhance operational efficiency.

Adaptive Pull Systems

Adaptive Pull Systems in Lean Manufacturing emphasize just-in-time production to minimize waste and inventory by responding directly to customer demand signals. In contrast, Smart Manufacturing integrates IoT sensors and real-time data analytics to dynamically adjust production flow, enhancing responsiveness and efficiency in adaptive pull systems.

MES-Driven Lean

MES-driven Lean manufacturing integrates Manufacturing Execution Systems to enhance real-time production monitoring, process optimization, and waste reduction, enabling more agile and data-driven decision-making on the shop floor. This approach contrasts with traditional Lean manufacturing by leveraging digital technologies and automation to improve operational efficiency, product quality, and responsiveness to market demands.

Data-Driven SMED

Data-driven SMED in Smart Manufacturing leverages real-time analytics and IoT integration to drastically reduce setup times, unlike Lean Manufacturing's traditional manual-focused approach. This advanced method enhances machine utilization and production agility by enabling predictive adjustments and continuous process optimization.

Intelligent Andon

Intelligent Andon integrates real-time data analytics and IoT sensors to enhance Lean Manufacturing by enabling immediate identification and resolution of production issues, reducing downtime and increasing efficiency. In Smart Manufacturing, this system evolves into a dynamic, AI-driven platform that not only signals problems but also predicts potential failures and automates workflow adjustments for proactive process optimization.

Predictive Kanban

Predictive Kanban in Lean Manufacturing enhances inventory management by using historical data and real-time monitoring to forecast demand, reducing waste and improving workflow efficiency. Smart Manufacturing integrates IoT sensors and AI-driven analytics in Predictive Kanban systems to optimize production schedules, minimize downtime, and enable proactive decision-making for agile supply chains.

Lean Manufacturing vs Smart Manufacturing Infographic

industrydif.com

industrydif.com