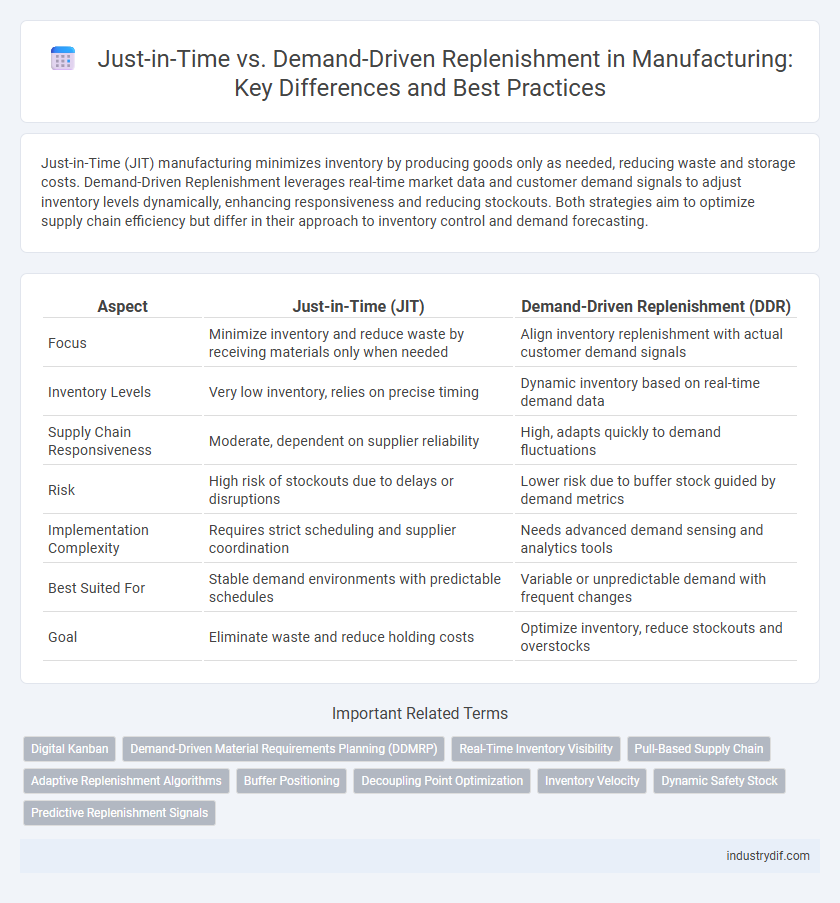

Just-in-Time (JIT) manufacturing minimizes inventory by producing goods only as needed, reducing waste and storage costs. Demand-Driven Replenishment leverages real-time market data and customer demand signals to adjust inventory levels dynamically, enhancing responsiveness and reducing stockouts. Both strategies aim to optimize supply chain efficiency but differ in their approach to inventory control and demand forecasting.

Table of Comparison

| Aspect | Just-in-Time (JIT) | Demand-Driven Replenishment (DDR) |

|---|---|---|

| Focus | Minimize inventory and reduce waste by receiving materials only when needed | Align inventory replenishment with actual customer demand signals |

| Inventory Levels | Very low inventory, relies on precise timing | Dynamic inventory based on real-time demand data |

| Supply Chain Responsiveness | Moderate, dependent on supplier reliability | High, adapts quickly to demand fluctuations |

| Risk | High risk of stockouts due to delays or disruptions | Lower risk due to buffer stock guided by demand metrics |

| Implementation Complexity | Requires strict scheduling and supplier coordination | Needs advanced demand sensing and analytics tools |

| Best Suited For | Stable demand environments with predictable schedules | Variable or unpredictable demand with frequent changes |

| Goal | Eliminate waste and reduce holding costs | Optimize inventory, reduce stockouts and overstocks |

Introduction to Just-in-Time (JIT) and Demand-Driven Replenishment

Just-in-Time (JIT) manufacturing minimizes inventory by producing goods only as needed, reducing waste and increasing efficiency. Demand-Driven Replenishment leverages real-time customer demand data to optimize inventory levels and supply chain responsiveness. Both methods aim to enhance operational agility but differ in execution, with JIT focusing on production timing and Demand-Driven Replenishment emphasizing demand signals integration.

Core Principles of Just-in-Time Manufacturing

Just-in-Time (JIT) manufacturing centers on minimizing inventory levels by producing goods only as they are needed, reducing waste and increasing efficiency. It relies heavily on precise demand forecasting, streamlined production processes, and strong supplier relationships to enable timely material delivery. JIT's core principles include continuous flow, pull-based production triggered by actual customer demand, and rigorous quality control to prevent defects and avoid costly downtime.

Key Concepts Behind Demand-Driven Replenishment

Demand-driven replenishment centers on synchronizing inventory levels with actual customer demand through real-time data analysis, minimizing excess stock and reducing lead times. It relies on continuous monitoring of consumption patterns and dynamic adjustment of supply orders, enhancing responsiveness to market fluctuations. This approach contrasts with traditional just-in-time methods by emphasizing adaptability and buffer management to prevent stockouts while optimizing inventory turnover.

Inventory Management: JIT vs Demand-Driven Approaches

Just-in-Time (JIT) inventory management minimizes stock levels by synchronizing production schedules with demand, reducing carrying costs but increasing vulnerability to supply chain disruptions. Demand-Driven Replenishment leverages real-time sales and consumption data to adjust inventory dynamically, enhancing responsiveness and reducing stockouts. Both approaches aim to optimize inventory turnover, yet Demand-Driven models provide greater flexibility in volatile market conditions.

Lead Time Reduction Strategies in Both Systems

Lead time reduction in Just-in-Time (JIT) manufacturing involves synchronizing production schedules with supplier deliveries to minimize inventory and accelerate throughput. Demand-Driven Replenishment emphasizes real-time consumption data to trigger replenishment, leveraging demand signals to shorten order cycles and enhance responsiveness. Both systems integrate advanced analytics and supplier collaboration platforms to streamline processes and reduce process variability, driving significant efficiencies in manufacturing operations.

Impact on Supply Chain Agility and Resilience

Just-in-Time (JIT) manufacturing emphasizes inventory reduction by synchronizing production closely with demand, which enhances supply chain agility through lean operations but can increase vulnerability to disruptions. Demand-Driven Replenishment leverages real-time data and market signals to adjust inventory and production dynamically, improving both agility and resilience by enabling rapid response to fluctuating customer demands and supply variability. Integrating demand-driven strategies with JIT principles can optimize supply chain performance by balancing efficiency with adaptive capacity.

Technology and Data Requirements for Implementation

Just-in-Time (JIT) manufacturing relies heavily on real-time data integration and precise inventory tracking systems to minimize stock levels and reduce waste, requiring advanced ERP software and IoT-enabled sensors for accurate demand forecasting. Demand-Driven Replenishment (DDR) leverages predictive analytics and adaptive algorithms powered by big data and AI to respond dynamically to actual customer demand signals, necessitating robust data pipelines and cloud-based platforms for continuous monitoring. Both approaches demand sophisticated technology infrastructures but DDR places a higher emphasis on flexible, data-driven decision-making tools to optimize supply chain responsiveness.

Cost Implications and Efficiency Gains

Just-in-Time (JIT) manufacturing minimizes inventory holding costs by synchronizing production closely with demand, but it risks costly disruptions from supply delays. Demand-Driven Replenishment leverages real-time data and buffer stocks to optimize inventory levels, reducing stockouts and excess inventory expenses while enhancing responsiveness. Implementing Demand-Driven Replenishment often leads to greater efficiency gains by balancing cost savings with improved supply chain flexibility.

Challenges and Risk Factors in Both Models

Just-in-Time (JIT) manufacturing faces challenges such as supplier reliability issues and limited inventory buffers, increasing risks of production delays due to supply chain disruptions. Demand-Driven Replenishment (DDR) struggles with accurate demand forecasting and requires advanced data analytics, which can lead to stockouts or excess inventory if predictions are off. Both models risk operational inefficiencies if communication between suppliers and manufacturers is weak or data integrity is compromised.

Best Practices for Choosing the Right Replenishment Strategy

Selecting the optimal replenishment strategy involves analyzing production lead times, inventory holding costs, and demand variability to balance efficiency and responsiveness. Just-in-Time (JIT) is ideal for environments with stable demand and reliable suppliers, minimizing inventory but requiring precise coordination. Demand-Driven Replenishment excels in dynamic markets by adapting inventory levels to real-time demand signals, enhancing flexibility and reducing stockouts.

Related Important Terms

Digital Kanban

Digital Kanban enhances demand-driven replenishment by providing real-time inventory visibility and enabling automatic trigger-based restocking, reducing lead times and minimizing stockouts. Unlike traditional Just-in-Time systems that rely heavily on forecast accuracy, Digital Kanban adapts dynamically to actual consumption patterns, improving production flow and operational efficiency.

Demand-Driven Material Requirements Planning (DDMRP)

Demand-Driven Material Requirements Planning (DDMRP) optimizes inventory levels and reduces lead times by dynamically adjusting replenishment based on actual demand signals rather than forecast-driven schedules, enhancing supply chain responsiveness and efficiency. DDMRP integrates strategic inventory positioning, buffer profiles, and demand-driven planning to synchronize material flow with real-time customer demand, outperforming traditional Just-in-Time methods in managing variability and ensuring production continuity.

Real-Time Inventory Visibility

Real-time inventory visibility enhances Just-in-Time and Demand-Driven Replenishment by providing accurate, up-to-the-minute stock levels that minimize excess inventory and reduce stockouts. Integrating advanced IoT sensors and AI-driven analytics enables manufacturers to synchronize supply with actual demand, optimizing production schedules and improving operational efficiency.

Pull-Based Supply Chain

Pull-based supply chain strategies, exemplified by Just-in-Time (JIT) and demand-driven replenishment, minimize inventory by aligning production closely with actual customer demand, reducing waste and enhancing responsiveness. Demand-driven replenishment improves adaptability by using real-time data and demand signals, whereas JIT emphasizes tight scheduling and supplier coordination to deliver components exactly when needed.

Adaptive Replenishment Algorithms

Adaptive replenishment algorithms enhance manufacturing efficiency by dynamically adjusting inventory levels in real-time based on fluctuating customer demand and production schedules, minimizing stockouts and overstock situations. These algorithms integrate machine learning with demand forecasting to optimize just-in-time (JIT) and demand-driven replenishment strategies, ensuring seamless supply chain responsiveness and reduced lead times.

Buffer Positioning

Buffer positioning in Just-in-Time (JIT) manufacturing is minimized to reduce inventory holding costs, relying on precise timing and supplier reliability to ensure components arrive exactly when needed. Demand-driven replenishment strategically places buffers at key decoupling points in the supply chain to protect against variability in demand and supply, enhancing flexibility and responsiveness.

Decoupling Point Optimization

Optimizing the decoupling point in manufacturing enhances responsiveness by aligning production closely with real-time demand, reducing lead times and inventory costs through demand-driven replenishment strategies. Just-in-Time systems minimize waste by synchronizing production schedules with supplier deliveries, but decoupling point optimization shifts focus to customer-driven signals, improving supply chain agility and inventory turnover.

Inventory Velocity

Just-in-Time inventory systems achieve high inventory velocity by synchronizing production schedules closely with demand, minimizing stock levels and reducing holding costs. Demand-Driven Replenishment enhances inventory velocity through real-time data analysis and adaptive supply chain responses, enabling faster adjustments to fluctuations in market demand and preventing stockouts.

Dynamic Safety Stock

Dynamic safety stock in Just-in-Time (JIT) manufacturing adjusts inventory levels based on real-time demand variability, reducing excess inventory while minimizing stockouts. In contrast, demand-driven replenishment uses advanced analytics to continuously update safety stock buffers, optimizing responsiveness to market fluctuations and supply chain disruptions.

Predictive Replenishment Signals

Just-in-Time (JIT) relies on precise scheduling and minimal inventory by aligning production closely with immediate demand, while Demand-Driven Replenishment harnesses predictive replenishment signals such as real-time sales data, market trends, and inventory levels to dynamically adjust supply chains. Predictive analytics in Demand-Driven Replenishment enhances responsiveness and reduces stockouts by forecasting demand fluctuations ahead of time, contrasting with JIT's reactive approach based primarily on fixed production schedules.

Just-in-Time vs Demand-Driven Replenishment Infographic

industrydif.com

industrydif.com