Supply Chain 4.0 transforms traditional supply chain management by integrating advanced technologies such as IoT, AI, and big data analytics to enhance transparency, efficiency, and responsiveness. Unlike conventional supply chains that rely on manual processes and siloed data, Supply Chain 4.0 enables real-time decision-making and predictive maintenance through interconnected digital systems. This evolution drives significant cost reductions, improved customer satisfaction, and agile adaptation to market fluctuations in manufacturing operations.

Table of Comparison

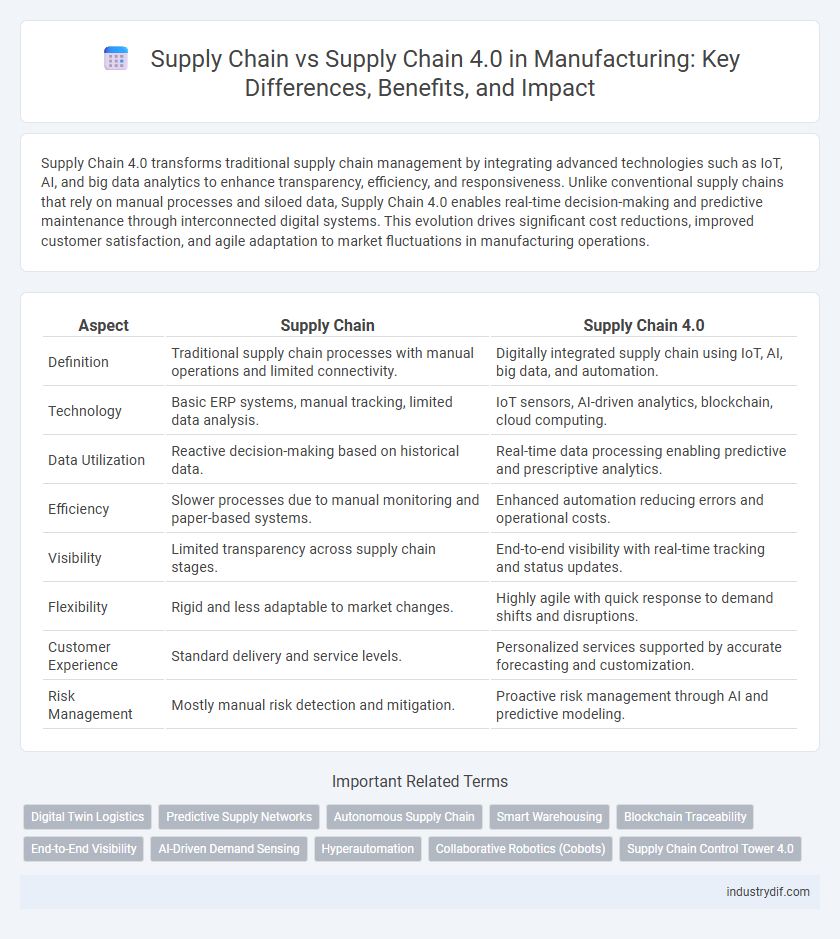

| Aspect | Supply Chain | Supply Chain 4.0 |

|---|---|---|

| Definition | Traditional supply chain processes with manual operations and limited connectivity. | Digitally integrated supply chain using IoT, AI, big data, and automation. |

| Technology | Basic ERP systems, manual tracking, limited data analysis. | IoT sensors, AI-driven analytics, blockchain, cloud computing. |

| Data Utilization | Reactive decision-making based on historical data. | Real-time data processing enabling predictive and prescriptive analytics. |

| Efficiency | Slower processes due to manual monitoring and paper-based systems. | Enhanced automation reducing errors and operational costs. |

| Visibility | Limited transparency across supply chain stages. | End-to-end visibility with real-time tracking and status updates. |

| Flexibility | Rigid and less adaptable to market changes. | Highly agile with quick response to demand shifts and disruptions. |

| Customer Experience | Standard delivery and service levels. | Personalized services supported by accurate forecasting and customization. |

| Risk Management | Mostly manual risk detection and mitigation. | Proactive risk management through AI and predictive modeling. |

Understanding Traditional Supply Chains

Traditional supply chains rely on linear processes involving suppliers, manufacturers, and distributors coordinating through manual communication and batch data processing. These conventional systems often face challenges such as limited real-time visibility, slower response times, and higher risk of errors due to fragmented information flow. Understanding the constraints of traditional supply chains highlights the need for digital transformation toward Supply Chain 4.0, which integrates IoT, AI, and real-time analytics to enhance efficiency and agility.

Introduction to Supply Chain 4.0

Supply Chain 4.0 integrates advanced technologies such as IoT, AI, and big data analytics to enhance real-time visibility and decision-making across the manufacturing supply network. This transformation enables predictive maintenance, optimized inventory management, and improved demand forecasting, driving operational efficiency and cost reduction. Traditional supply chains rely on linear processes, whereas Supply Chain 4.0 emphasizes interconnected, automated, and intelligent systems for end-to-end supply chain optimization.

Key Differences Between Supply Chain and Supply Chain 4.0

Supply Chain 4.0 integrates advanced digital technologies such as IoT, AI, and blockchain, enabling real-time data analytics and enhanced automation, unlike traditional supply chains that rely on manual processes and limited visibility. The shift to Supply Chain 4.0 fosters improved demand forecasting, increased operational efficiency, and greater agility through interconnected systems. Enhanced transparency and predictive maintenance are critical differentiators that optimize inventory management and reduce downtime in Supply Chain 4.0 environments.

Core Technologies Driving Supply Chain 4.0

Supply Chain 4.0 integrates advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and blockchain to enhance real-time visibility and predictive analytics. Robotics and automation streamline operations, while big data analytics optimize demand forecasting and inventory management. These core technologies enable smarter, more agile, and resilient manufacturing supply chains compared to traditional supply chains.

Integration of IoT and Automation

Supply Chain 4.0 revolutionizes traditional supply chains by integrating IoT and automation technologies, enabling real-time data collection, enhanced visibility, and predictive analytics. IoT sensors monitor inventory levels and equipment performance, while automation streamlines repetitive tasks, reducing operational costs and errors. This interconnected system enhances decision-making and responsiveness, driving efficiency and agility across manufacturing supply networks.

Data Analytics and Real-Time Visibility

Supply Chain 4.0 leverages advanced data analytics to enhance decision-making through predictive insights and demand forecasting, surpassing traditional supply chain methods that rely on historical data analysis. Real-time visibility enabled by IoT sensors and integrated platforms allows manufacturers to monitor inventory levels, production status, and logistics in real time, reducing delays and optimizing resource allocation. This digital transformation facilitates agile responses to market fluctuations, improving overall supply chain efficiency and resilience.

Impact on Efficiency and Responsiveness

Supply Chain 4.0 leverages advanced technologies like IoT, AI, and big data analytics to enhance real-time visibility and predictive capabilities, significantly improving operational efficiency compared to traditional supply chains. Digital integration enables faster decision-making and agile responses to market fluctuations, reducing lead times and minimizing disruptions. The adoption of automated processes and smart sensors optimizes inventory management and logistics, resulting in a more responsive and resilient supply chain ecosystem.

Challenges in Adopting Supply Chain 4.0

Supply Chain 4.0 integrates advanced technologies such as IoT, AI, and blockchain to enhance transparency, automation, and real-time data analytics, transforming traditional supply chain operations. Challenges in adopting Supply Chain 4.0 include high implementation costs, the need for skilled workforce in digital technologies, and data security concerns due to increased connectivity. Resistance to change within organizations and integration complexities with existing legacy systems also hinder seamless transition to Supply Chain 4.0.

Workforce Evolution in the Digital Supply Chain

Workforce evolution in Supply Chain 4.0 emphasizes advanced digital skills, automation proficiency, and data analytics expertise, transforming traditional supply chain roles. Employees leverage IoT, AI, and machine learning tools to optimize operations, improve forecasting, and enhance decision-making processes. This digital supply chain demands continuous upskilling and adaptability to integrate smart technologies effectively throughout manufacturing and logistics.

Future Trends in Supply Chain Management

Supply Chain 4.0 integrates advanced technologies such as IoT, AI, and blockchain to create more agile, transparent, and efficient manufacturing processes compared to traditional supply chain models. Future trends emphasize predictive analytics for demand forecasting, autonomous logistics through robotics, and digital twin simulations to optimize inventory and reduce operational risks. Embracing these innovations enables manufacturers to enhance real-time decision-making, improve sustainability, and drive competitive advantage in a rapidly evolving global market.

Related Important Terms

Digital Twin Logistics

Supply Chain 4.0 integrates advanced technologies such as Digital Twin Logistics to create real-time, dynamic simulations of supply chain operations, enabling predictive analytics and enhanced decision-making. This contrasts with traditional Supply Chain models by significantly improving efficiency, transparency, and responsiveness through continuous digital monitoring and optimization.

Predictive Supply Networks

Supply Chain 4.0 integrates advanced technologies such as IoT, AI, and big data analytics to transform traditional supply chains into Predictive Supply Networks, enabling real-time demand forecasting and proactive risk management. These networks leverage machine learning algorithms to analyze data from multiple sources, optimize inventory levels, reduce lead times, and enhance overall production efficiency.

Autonomous Supply Chain

Supply Chain 4.0 integrates advanced automation, IoT, and AI technologies to create an Autonomous Supply Chain capable of real-time decision-making and predictive analytics. This shift enhances efficiency, reduces human error, and enables seamless end-to-end visibility across manufacturing operations.

Smart Warehousing

Smart warehousing in Supply Chain 4.0 integrates IoT sensors, AI-driven inventory management, and real-time data analytics to optimize storage efficiency and reduce operational costs compared to traditional supply chain methods. Enhanced automation and predictive maintenance improve agility and accuracy in demand forecasting, enabling faster response times and minimized stockouts.

Blockchain Traceability

Supply Chain 4.0 integrates blockchain technology to enhance traceability by providing immutable, real-time tracking of goods and materials, reducing fraud and errors compared to traditional supply chains. This digital transformation enables manufacturers to improve transparency, streamline inventory management, and ensure product authenticity throughout the entire supply chain.

End-to-End Visibility

Supply Chain 4.0 enhances traditional supply chain models by integrating IoT sensors, real-time data analytics, and AI-driven decision-making to achieve comprehensive end-to-end visibility, enabling proactive risk management and optimized inventory control. This transformation supports seamless tracking of materials and products across all stages, from raw material sourcing to final delivery, significantly reducing delays and improving overall operational efficiency.

AI-Driven Demand Sensing

Supply Chain 4.0 leverages AI-driven demand sensing to enhance forecasting accuracy by analyzing real-time data from IoT devices, social media, and market trends, reducing inventory costs and stockouts. Traditional supply chains rely on historical data and manual processes, limiting responsiveness and agility compared to the predictive capabilities enabled by AI technologies in Supply Chain 4.0.

Hyperautomation

Supply Chain 4.0 leverages hyperautomation by integrating AI, IoT, and advanced robotics to streamline manufacturing processes, significantly reducing lead times and operational costs compared to traditional supply chains. This digital transformation enhances real-time data analytics and predictive maintenance, driving efficiency and agility in production and logistics management.

Collaborative Robotics (Cobots)

Collaborative robotics (cobots) in Supply Chain 4.0 revolutionize manufacturing by seamlessly integrating human-robot teamwork, enhancing real-time data exchange, and optimizing production flexibility. Unlike traditional supply chains, Supply Chain 4.0 leverages cobots equipped with AI and IoT connectivity to improve precision, reduce downtime, and accelerate order fulfillment cycles.

Supply Chain Control Tower 4.0

Supply Chain Control Tower 4.0 leverages real-time data analytics, IoT devices, and AI-driven insights to enhance visibility and predictability across complex supply networks, enabling faster decision-making and proactive risk management. Unlike traditional supply chain models, this advanced framework integrates end-to-end digital monitoring, facilitating seamless collaboration between suppliers, manufacturers, and logistics partners to optimize efficiency and reduce operational costs.

Supply Chain vs Supply Chain 4.0 Infographic

industrydif.com

industrydif.com