Quality control in manufacturing relies on inspecting products after production to identify defects and ensure standards are met, often leading to reactive problem-solving. Predictive quality analytics uses data-driven models and machine learning to forecast potential defects and optimize processes before issues arise, enhancing efficiency and reducing waste. Integrating predictive analytics with traditional quality control enables manufacturers to transition from reactive to proactive quality management, improving product reliability and customer satisfaction.

Table of Comparison

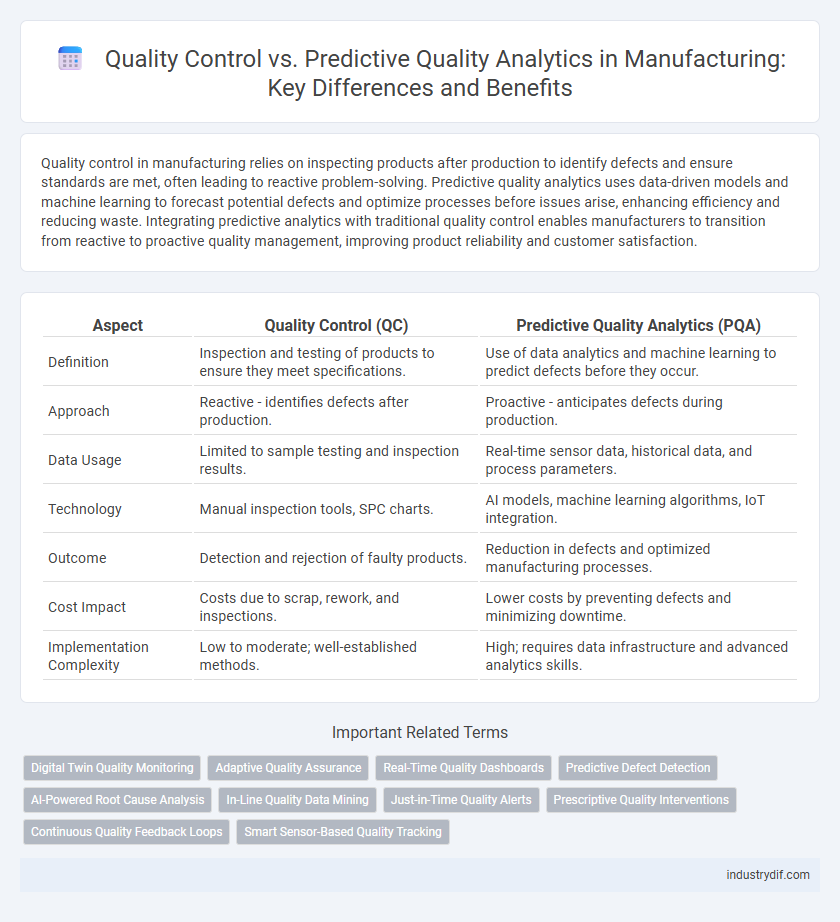

| Aspect | Quality Control (QC) | Predictive Quality Analytics (PQA) |

|---|---|---|

| Definition | Inspection and testing of products to ensure they meet specifications. | Use of data analytics and machine learning to predict defects before they occur. |

| Approach | Reactive - identifies defects after production. | Proactive - anticipates defects during production. |

| Data Usage | Limited to sample testing and inspection results. | Real-time sensor data, historical data, and process parameters. |

| Technology | Manual inspection tools, SPC charts. | AI models, machine learning algorithms, IoT integration. |

| Outcome | Detection and rejection of faulty products. | Reduction in defects and optimized manufacturing processes. |

| Cost Impact | Costs due to scrap, rework, and inspections. | Lower costs by preventing defects and minimizing downtime. |

| Implementation Complexity | Low to moderate; well-established methods. | High; requires data infrastructure and advanced analytics skills. |

Defining Quality Control in Manufacturing

Quality Control in manufacturing involves systematic inspection and testing of products to ensure they meet predefined standards and specifications. It relies on established procedures to detect defects and prevent non-conforming products from reaching customers, thereby maintaining brand reputation. Traditional QC focuses on sampling and reactive measures, while emerging predictive quality analytics use data-driven models to anticipate defects before they occur.

Introduction to Predictive Quality Analytics

Predictive Quality Analytics leverages advanced machine learning algorithms and real-time data from manufacturing processes to forecast defects and optimize product quality. Unlike traditional Quality Control, which relies on post-production inspection, predictive analytics enables proactive interventions by identifying potential quality issues before they occur. This shift enhances manufacturing efficiency, reduces waste, and improves customer satisfaction through data-driven decision-making.

Key Differences Between Quality Control and Predictive Quality Analytics

Quality control relies on manual inspections and predefined standards to detect defects in manufactured products, ensuring compliance with established quality criteria in real-time. Predictive quality analytics utilizes machine learning algorithms and historical production data to forecast potential failures and optimize manufacturing processes before defects occur. The key difference lies in quality control's reactive approach versus predictive quality analytics' proactive capability to prevent quality issues and reduce downtime.

Traditional Quality Control Methods and Tools

Traditional quality control methods in manufacturing rely heavily on manual inspections, statistical process control (SPC), and physical sampling to identify defects and ensure product standards. Tools such as control charts, check sheets, and cause-and-effect diagrams help monitor production processes and detect variations in real-time. These methods emphasize reactive detection of quality issues rather than proactive prediction, often leading to delays in addressing root causes.

How Predictive Quality Analytics Transforms Manufacturing

Predictive Quality Analytics revolutionizes manufacturing by leveraging machine learning algorithms and real-time data to anticipate product defects before they occur, reducing waste and enhancing production efficiency. Unlike traditional Quality Control, which inspects products after manufacturing, this technology enables proactive decision-making and continuous process improvements. Integrating predictive models with Internet of Things (IoT) sensors, manufacturers achieve higher yield rates and lower downtime, driving overall operational excellence.

Data Sources for Predictive Quality Analytics

Predictive Quality Analytics relies heavily on diverse data sources including real-time sensor data from manufacturing equipment, historical production records, and supplier quality metrics to identify potential defects before they occur. Integration of machine learning algorithms with these datasets enables early detection of quality deviations, reducing waste and improving process efficiency. Data from environmental conditions, operator actions, and maintenance logs further enhance the accuracy of predictive models in manufacturing quality control.

Benefits of Transitioning from QC to Predictive Quality Analytics

Shifting from traditional Quality Control to Predictive Quality Analytics in manufacturing enhances real-time defect detection, reduces downtime, and lowers production costs by anticipating issues before they occur. Predictive analytics leverages machine learning algorithms and sensor data to improve process optimization and maintain consistent product quality. This proactive approach leads to higher customer satisfaction and a significant competitive advantage in the manufacturing industry.

Implementation Challenges and Considerations

Implementing traditional quality control in manufacturing often faces challenges such as manual inspection bottlenecks, inconsistent data recording, and limited real-time feedback, which hinder timely defect detection. Predictive quality analytics requires integrating advanced sensors, machine learning algorithms, and robust data infrastructure, demanding significant investment in technology and skilled personnel. Considerations include ensuring data accuracy, managing cybersecurity risks, and aligning predictive models with specific production processes to achieve effective quality improvements.

Real-world Case Studies: QC vs. Predictive Quality Analytics

Real-world case studies reveal that traditional Quality Control (QC) relies heavily on post-production inspection, identifying defects after they occur, which often leads to delayed responses and increased waste. Predictive Quality Analytics leverages machine learning algorithms and sensor data to anticipate product failures in real time, enabling proactive adjustments during the manufacturing process. This shift not only enhances defect detection accuracy by up to 30% but also reduces downtime and improves overall production efficiency.

Future Trends in Quality Management for Manufacturing

Quality control in manufacturing traditionally relies on inspection and defect detection, but predictive quality analytics uses advanced data models and machine learning to forecast potential defects before they occur. Future trends emphasize the integration of IoT sensors and real-time data streams to enable continuous quality monitoring and automated corrective actions. This shift towards predictive analytics drives higher product reliability, reduces downtime, and optimizes manufacturing processes for improved efficiency.

Related Important Terms

Digital Twin Quality Monitoring

Digital Twin Quality Monitoring leverages real-time data to simulate manufacturing processes, enabling predictive quality analytics that surpass traditional quality control by identifying defects before production completion. Embedding digital twins in quality monitoring enhances defect prediction accuracy, reduces waste, and optimizes process adjustments through continuous virtual feedback loops.

Adaptive Quality Assurance

Adaptive Quality Assurance leverages predictive quality analytics to dynamically adjust manufacturing processes in real-time, minimizing defects and optimizing product consistency. Unlike traditional quality control, this approach utilizes machine learning models and sensor data to foresee potential failures and implement corrective actions before deviations occur.

Real-Time Quality Dashboards

Real-time quality dashboards transform manufacturing quality control by providing immediate insights into production processes, enabling instant detection and resolution of defects to minimize downtime. Predictive quality analytics enhances these dashboards by leveraging machine learning algorithms to forecast potential quality issues before they occur, optimizing product consistency and reducing waste.

Predictive Defect Detection

Predictive Quality Analytics leverages machine learning algorithms and real-time sensor data to identify potential defects before they occur, significantly reducing waste and downtime in manufacturing processes. Unlike traditional Quality Control, which relies on post-production inspections, predictive defect detection enables proactive adjustments by analyzing patterns and anomalies to ensure consistent product quality.

AI-Powered Root Cause Analysis

Quality Control ensures product standards through inspection and testing, while Predictive Quality Analytics leverages AI-powered root cause analysis to identify potential defects before they occur. This AI-driven approach enhances manufacturing efficiency by analyzing data patterns and pinpointing complex failure sources, enabling proactive quality improvement.

In-Line Quality Data Mining

In-line quality data mining leverages real-time sensor data and machine learning algorithms to detect patterns and anomalies during the manufacturing process, enabling predictive quality analytics to forecast defects before they occur. This proactive approach surpasses traditional quality control by minimizing downtime, reducing scrap rates, and enhancing overall product consistency.

Just-in-Time Quality Alerts

Just-in-Time Quality Alerts in manufacturing enhance traditional Quality Control by leveraging Predictive Quality Analytics to identify potential defects before they occur, reducing waste and downtime. This approach integrates real-time data monitoring and machine learning algorithms to enable proactive interventions, ensuring consistent product quality and operational efficiency.

Prescriptive Quality Interventions

Prescriptive quality interventions leverage predictive quality analytics by using data-driven insights to recommend targeted actions that prevent defects and optimize manufacturing processes. Unlike traditional quality control methods that identify issues after production, prescriptive analytics enables proactive decision-making to enhance product quality and reduce downtime.

Continuous Quality Feedback Loops

Continuous quality feedback loops in manufacturing integrate real-time data monitoring with predictive quality analytics to identify and address defects earlier than traditional quality control methods. This proactive approach enhances process optimization, reduces scrap rates, and improves overall product consistency by enabling dynamic adjustments throughout the production cycle.

Smart Sensor-Based Quality Tracking

Smart sensor-based quality tracking in manufacturing enables real-time monitoring of production processes, providing precise data to detect defects early and reduce waste. Predictive quality analytics leverage this sensor data to forecast potential quality issues, optimizing maintenance schedules and improving overall product reliability.

Quality Control vs Predictive Quality Analytics Infographic

industrydif.com

industrydif.com