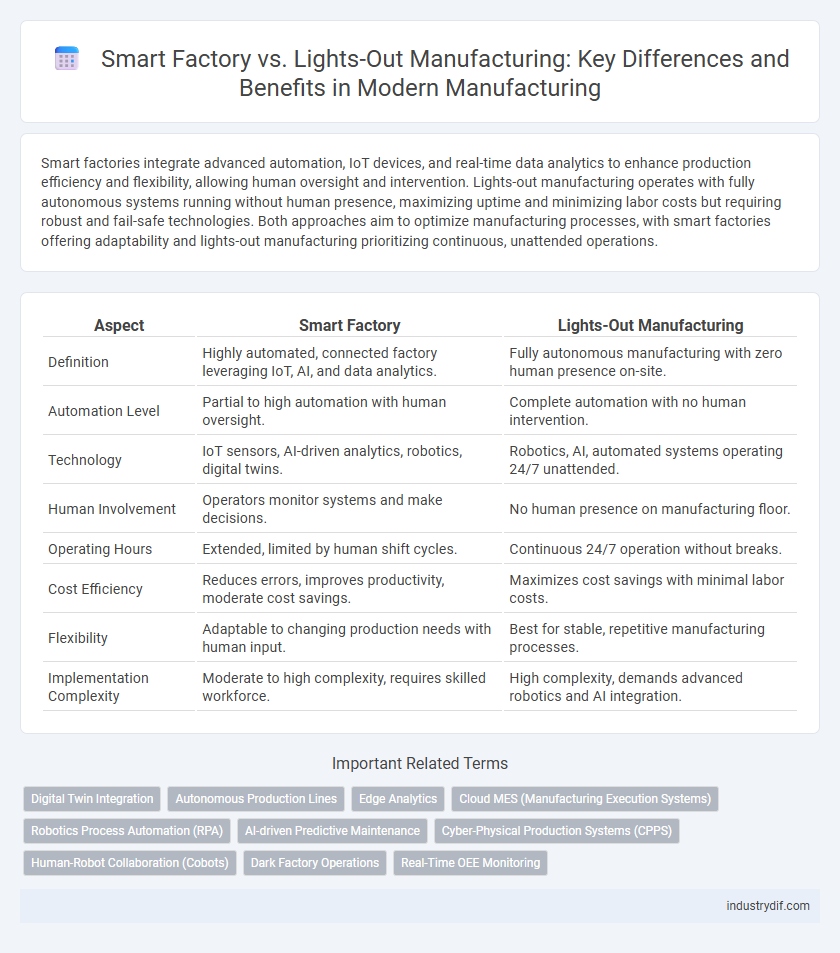

Smart factories integrate advanced automation, IoT devices, and real-time data analytics to enhance production efficiency and flexibility, allowing human oversight and intervention. Lights-out manufacturing operates with fully autonomous systems running without human presence, maximizing uptime and minimizing labor costs but requiring robust and fail-safe technologies. Both approaches aim to optimize manufacturing processes, with smart factories offering adaptability and lights-out manufacturing prioritizing continuous, unattended operations.

Table of Comparison

| Aspect | Smart Factory | Lights-Out Manufacturing |

|---|---|---|

| Definition | Highly automated, connected factory leveraging IoT, AI, and data analytics. | Fully autonomous manufacturing with zero human presence on-site. |

| Automation Level | Partial to high automation with human oversight. | Complete automation with no human intervention. |

| Technology | IoT sensors, AI-driven analytics, robotics, digital twins. | Robotics, AI, automated systems operating 24/7 unattended. |

| Human Involvement | Operators monitor systems and make decisions. | No human presence on manufacturing floor. |

| Operating Hours | Extended, limited by human shift cycles. | Continuous 24/7 operation without breaks. |

| Cost Efficiency | Reduces errors, improves productivity, moderate cost savings. | Maximizes cost savings with minimal labor costs. |

| Flexibility | Adaptable to changing production needs with human input. | Best for stable, repetitive manufacturing processes. |

| Implementation Complexity | Moderate to high complexity, requires skilled workforce. | High complexity, demands advanced robotics and AI integration. |

Defining the Smart Factory: Key Concepts

The Smart Factory integrates advanced IoT devices, AI-driven analytics, and real-time data processing to enable adaptive production processes and predictive maintenance. Unlike Lights-Out Manufacturing, which operates fully autonomously without human intervention, Smart Factories emphasize human-machine collaboration to optimize efficiency and flexibility. Core concepts include cyber-physical systems, digital twins, and decentralized decision-making to achieve seamless connectivity and enhanced operational intelligence.

Understanding Lights-Out Manufacturing

Lights-Out Manufacturing refers to fully automated production processes that operate without human intervention, utilizing advanced robotics, AI-driven systems, and IoT connectivity to maximize efficiency and reduce operational costs. Unlike Smart Factories, which integrate human decision-making with digital technologies for flexible manufacturing, Lights-Out Manufacturing emphasizes unattended operations to achieve continuous, error-free production. This approach significantly enhances throughput and quality control while minimizing labor dependency and facility footprint.

Core Technologies Powering Each Approach

Smart factories leverage IoT sensors, AI-driven analytics, and advanced robotics to enable real-time monitoring and adaptive process control, enhancing operational flexibility and efficiency. Lights-out manufacturing relies heavily on fully autonomous robotics, machine learning algorithms, and integrated automation systems to facilitate continuous, human-free production environments. Both approaches utilize cloud computing and digital twins, but smart factories emphasize sensor data integration while lights-out manufacturing prioritizes complete automation and minimal human intervention.

Automation Levels: Comparing Smart and Lights-Out Factories

Smart factories integrate advanced automation with human oversight, utilizing sensors, IoT devices, and AI to optimize production processes. Lights-out manufacturing reaches a higher automation level by operating entirely without human intervention, relying on fully autonomous robots and systems. The key distinction lies in the extent of human presence, where smart factories enhance human-machine collaboration, and lights-out manufacturing achieves complete automation for continuous, unattended production.

Human Roles: Collaboration vs. Full Autonomy

Smart Factory models emphasize human roles where collaboration between workers and intelligent systems enhances decision-making and process optimization, leveraging real-time data and IoT connectivity. In contrast, lights-out manufacturing aims for full autonomy, minimizing human intervention by utilizing advanced robotics and AI to operate continuously without on-site personnel. The shift from collaborative human-machine interaction to complete autonomy reflects differing priorities in operational flexibility versus efficiency and reliability in manufacturing environments.

Data Integration and Connectivity

Smart Factory and Lights-Out Manufacturing both emphasize data integration and connectivity to enhance operational efficiency. Smart Factories utilize interconnected IoT devices and real-time analytics platforms to enable dynamic decision-making and predictive maintenance. Lights-Out Manufacturing advances this concept by implementing fully automated systems with minimal human intervention, relying heavily on seamless machine-to-machine communication and centralized data management.

Scalability and Flexibility in Operations

Smart Factory technology leverages interconnected systems and real-time data analytics to enhance operational scalability by enabling adaptive production processes that respond swiftly to changing demands. Lights-Out Manufacturing, characterized by fully autonomous, unmanned production environments, offers high scalability through continuous operation but often sacrifices flexibility due to fixed, preprogrammed workflows. Integrating adaptive control systems in Smart Factories facilitates a balance between scalability and flexibility, whereas Lights-Out setups prioritize efficiency and volume over dynamic operational changes.

Challenges and Limitations of Each Model

Smart factories face challenges such as high initial investment costs, integration complexities with legacy systems, and cybersecurity risks due to extensive IoT connectivity. Lights-out manufacturing demands fully autonomous operations, which are limited by current AI capabilities, equipment reliability, and the inability to adapt quickly to unexpected disruptions without human intervention. Both models struggle with workforce skill gaps and require significant technological upgrades to realize their full potential.

Industry Applications and Case Studies

Smart factories integrate IoT sensors, AI-driven analytics, and robotics to enable real-time decision making and adaptive production lines, exemplified by Siemens' Amberg facility, which increased efficiency by 20%. Lights-out manufacturing operates entirely without human intervention, utilizing advanced automation and AI to maintain 24/7 production, as demonstrated by FANUC's robot-operated plant achieving near-zero downtime. Industry applications reveal smart factories excel in flexible, data-driven customization, while lights-out manufacturing optimizes high-volume, repetitive tasks with minimal human oversight.

Future Trends in Factory Automation

Smart Factory technology integrates IoT, AI, and advanced robotics to enhance real-time data analytics and adaptive process control, driving increased operational efficiency and product customization. Lights-Out Manufacturing emphasizes fully autonomous production lines with zero human intervention, relying on AI-powered robots and predictive maintenance systems to minimize downtime and maximize throughput. Future trends point to hybrid models combining human insight with intelligent automation, leveraging edge computing and 5G connectivity to enable seamless factory digitization and scalable, flexible manufacturing environments.

Related Important Terms

Digital Twin Integration

Smart Factory leverages Digital Twin integration to create real-time virtual models of production processes, enabling predictive maintenance and process optimization. Lights-Out Manufacturing utilizes these digital replicas for fully autonomous operations, minimizing human intervention and maximizing efficiency.

Autonomous Production Lines

Autonomous production lines in smart factories leverage IoT sensors, AI-driven robotics, and real-time data analytics to optimize manufacturing processes with minimal human intervention. Lights-out manufacturing takes this automation further by enabling fully unattended operations, maximizing efficiency and reducing labor costs through continuous, 24/7 autonomous production.

Edge Analytics

Smart Factory leverages Edge Analytics to collect and analyze real-time data from connected devices, enabling rapid decision-making and predictive maintenance to enhance production efficiency. Lights-Out Manufacturing integrates advanced Edge Analytics with fully automated systems, minimizing human intervention and maximizing operational uptime through autonomous error detection and correction.

Cloud MES (Manufacturing Execution Systems)

Cloud MES platforms enable smart factories to integrate real-time data analytics and IoT connectivity, enhancing production efficiency and flexibility. Lights-out manufacturing leverages Cloud MES for fully autonomous operations, minimizing human intervention while maximizing uptime and predictive maintenance.

Robotics Process Automation (RPA)

Smart Factory integrates Robotics Process Automation (RPA) to enhance flexibility and real-time decision-making within interconnected manufacturing systems, enabling dynamic adjustments to production processes. Lights-Out Manufacturing relies heavily on RPA to achieve fully autonomous operations with minimal human intervention, optimizing efficiency through continuous, unattended robotic workflows.

AI-driven Predictive Maintenance

AI-driven predictive maintenance in smart factories utilizes real-time data analytics and machine learning algorithms to anticipate equipment failures, minimizing downtime and optimizing operational efficiency. In contrast, lights-out manufacturing fully automates production with minimal human intervention, relying heavily on AI for continuous condition monitoring and predictive maintenance to ensure uninterrupted, autonomous operations.

Cyber-Physical Production Systems (CPPS)

Cyber-Physical Production Systems (CPPS) integrate computational algorithms and physical processes, enabling Smart Factories to optimize real-time data exchange for adaptive manufacturing environments. Lights-Out Manufacturing represents an advanced CPPS implementation where fully automated production operates without human intervention, leveraging AI and IoT to enhance efficiency and reduce downtime.

Human-Robot Collaboration (Cobots)

Smart Factory integrates human-robot collaboration through cobots that enhance flexibility and decision-making by working alongside operators in real time. Lights-Out Manufacturing relies on fully autonomous systems with minimal human intervention, prioritizing continuous, unattended production but limiting direct human-robot interaction.

Dark Factory Operations

Dark factory operations represent a fully automated manufacturing environment where human presence is unnecessary, enabling continuous production with minimal downtime and enhanced precision. Unlike general smart factory implementations, dark factories leverage advanced robotics, AI-driven monitoring, and IoT-enabled systems to achieve zero-defect manufacturing and optimize energy efficiency.

Real-Time OEE Monitoring

Real-time OEE monitoring in smart factories leverages IoT sensors and advanced analytics to continuously track equipment performance, availability, and quality, enabling immediate response to inefficiencies. Lights-out manufacturing emphasizes autonomous operation with AI-driven OEE systems that predict maintenance needs and optimize production flow without human intervention, maximizing uptime and throughput.

Smart Factory vs Lights-Out Manufacturing Infographic

industrydif.com

industrydif.com