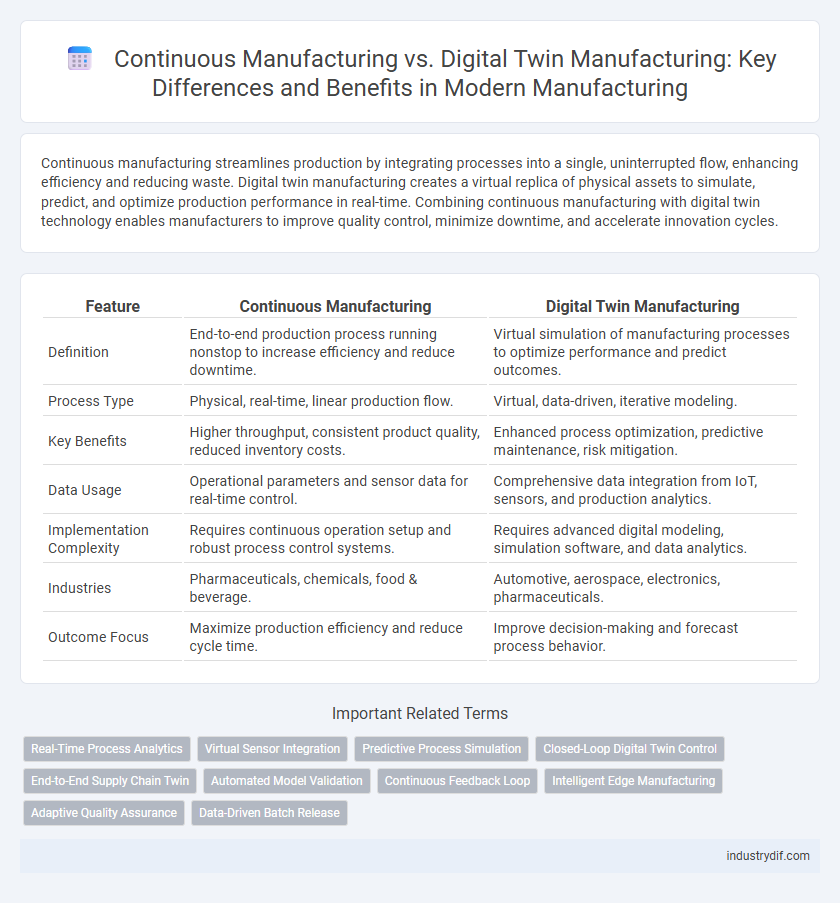

Continuous manufacturing streamlines production by integrating processes into a single, uninterrupted flow, enhancing efficiency and reducing waste. Digital twin manufacturing creates a virtual replica of physical assets to simulate, predict, and optimize production performance in real-time. Combining continuous manufacturing with digital twin technology enables manufacturers to improve quality control, minimize downtime, and accelerate innovation cycles.

Table of Comparison

| Feature | Continuous Manufacturing | Digital Twin Manufacturing |

|---|---|---|

| Definition | End-to-end production process running nonstop to increase efficiency and reduce downtime. | Virtual simulation of manufacturing processes to optimize performance and predict outcomes. |

| Process Type | Physical, real-time, linear production flow. | Virtual, data-driven, iterative modeling. |

| Key Benefits | Higher throughput, consistent product quality, reduced inventory costs. | Enhanced process optimization, predictive maintenance, risk mitigation. |

| Data Usage | Operational parameters and sensor data for real-time control. | Comprehensive data integration from IoT, sensors, and production analytics. |

| Implementation Complexity | Requires continuous operation setup and robust process control systems. | Requires advanced digital modeling, simulation software, and data analytics. |

| Industries | Pharmaceuticals, chemicals, food & beverage. | Automotive, aerospace, electronics, pharmaceuticals. |

| Outcome Focus | Maximize production efficiency and reduce cycle time. | Improve decision-making and forecast process behavior. |

Introduction to Continuous Manufacturing

Continuous manufacturing integrates real-time production processes, enabling constant material flow and reducing downtime for enhanced efficiency. It leverages advanced automation and sensor data to maintain consistent product quality and minimize variability. This method contrasts with batch processing by delivering faster throughput and streamlined operations within the manufacturing environment.

Understanding Digital Twin Manufacturing

Digital Twin Manufacturing leverages real-time data integration and advanced simulations to create a virtual replica of the entire production process, enabling precise monitoring, predictive maintenance, and process optimization. Unlike traditional Continuous Manufacturing, which focuses on uninterrupted production flow, Digital Twin Manufacturing provides dynamic insights that enhance decision-making, reduce downtime, and improve product quality. This approach combines IoT sensors, AI analytics, and cloud computing to enable adaptive manufacturing strategies that respond instantly to operational changes.

Core Principles: Continuous vs Digital Twin Manufacturing

Continuous Manufacturing emphasizes an uninterrupted, streamlined production flow by integrating real-time process monitoring and automation to optimize efficiency and reduce waste. Digital Twin Manufacturing leverages virtual replicas of physical production systems to simulate, analyze, and optimize processes, enabling predictive maintenance and enhanced decision-making. Core principles distinguish Continuous Manufacturing's focus on steadfast operational continuity from Digital Twin Manufacturing's reliance on advanced simulation for process innovation and control.

Technological Foundations of Each Approach

Continuous Manufacturing relies on real-time process monitoring and advanced automation systems, utilizing sensors, control algorithms, and feedback loops to ensure steady-state production and consistent product quality. Digital Twin Manufacturing is built on cyber-physical systems, integrating IoT devices, data analytics, and virtual simulation models to create a dynamic digital replica of physical manufacturing processes for predictive analysis and optimization. Both approaches harness Industry 4.0 technologies, but Continuous Manufacturing emphasizes process stability through automation while Digital Twin Manufacturing focuses on virtual modeling and real-time data integration for proactive decision-making.

Key Benefits of Continuous Manufacturing

Continuous manufacturing enhances production efficiency by enabling nonstop operations, reducing batch-to-batch variability, and minimizing downtime. It improves product quality through consistent process control and real-time monitoring, leading to higher yield and reduced waste. This manufacturing approach accelerates time-to-market and lowers operational costs, driving competitive advantages in industries like pharmaceuticals and chemicals.

Advantages of Digital Twin Technology in Manufacturing

Digital Twin technology in manufacturing enables real-time simulation and monitoring of production processes, leading to enhanced predictive maintenance and reduced downtime. It allows for virtual prototyping and process optimization, which decreases costs and accelerates product development cycles. This integration improves decision-making accuracy and operational efficiency compared to traditional continuous manufacturing systems.

Challenges and Limitations: Continuous vs Digital Twin

Continuous manufacturing faces challenges such as complex process control, equipment integration, and real-time quality monitoring, which can limit flexibility and scalability. Digital twin manufacturing struggles with high initial costs, data accuracy requirements, and cybersecurity risks, impacting implementation and reliability. Both approaches require significant investments in technology and skilled personnel to overcome these limitations and achieve optimal production efficiency.

Real-World Applications and Case Studies

Continuous manufacturing enhances production efficiency by enabling nonstop processes in pharmaceuticals and electronics, reducing downtime and waste. Digital twin manufacturing leverages virtual replicas to simulate, predict, and optimize operations in automotive and aerospace industries, improving quality control and maintenance planning. Case studies from companies like Siemens and Pfizer demonstrate significant cost savings, faster time-to-market, and enhanced product consistency using these advanced manufacturing approaches.

Future Trends in Manufacturing Technologies

Continuous Manufacturing leverages real-time data and automated processes to enhance production efficiency and product consistency, driving significant advancements in pharmaceutical and automotive industries. Digital Twin Manufacturing integrates virtual replicas of physical assets to enable predictive maintenance, optimize workflows, and reduce operational costs through advanced simulation and AI analytics. Emerging trends emphasize the convergence of continuous manufacturing and digital twin technologies to create adaptive, intelligent production environments that respond dynamically to market demands and supply chain fluctuations.

Selecting the Right Manufacturing Strategy

Selecting the right manufacturing strategy involves evaluating continuous manufacturing's ability to enhance production efficiency through real-time process control against digital twin manufacturing's capacity for virtual simulation and predictive analytics. Continuous manufacturing offers high throughput and consistent product quality, while digital twin technology enables proactive identification of potential issues and optimization of production parameters before physical implementation. Integrating digital twins within continuous manufacturing workflows can lead to smarter, more adaptive production systems that reduce downtime and boost overall operational performance.

Related Important Terms

Real-Time Process Analytics

Continuous Manufacturing leverages real-time process analytics to monitor and adjust production parameters instantaneously, ensuring consistent quality and efficiency in high-volume output. Digital Twin Manufacturing integrates real-time data with virtual replicas of production systems, enabling predictive analysis and proactive adjustments that enhance process optimization and reduce downtime.

Virtual Sensor Integration

Continuous manufacturing leverages real-time data streams to optimize production efficiency, while digital twin manufacturing enhances this process by integrating virtual sensors that simulate physical sensor inputs for predictive analytics and process control. Virtual sensor integration in digital twin manufacturing enables precise monitoring and anomaly detection without additional hardware, driving higher accuracy in quality control and reducing downtime.

Predictive Process Simulation

Continuous Manufacturing leverages real-time data and automation to maintain consistent production flow, while Digital Twin Manufacturing enhances predictive process simulation by creating virtual replicas of physical manufacturing systems to anticipate and mitigate potential disruptions. Predictive process simulation in Digital Twin Manufacturing enables precise forecasting of system behavior under varying conditions, optimizing efficiency and reducing downtime compared to traditional continuous manufacturing methods.

Closed-Loop Digital Twin Control

Closed-loop digital twin control in manufacturing enables real-time monitoring and adaptive adjustments by continuously syncing virtual models with physical processes, significantly enhancing process optimization and product quality. Unlike traditional continuous manufacturing, this approach integrates dynamic feedback to predict and correct deviations, reducing downtime and material waste.

End-to-End Supply Chain Twin

Continuous manufacturing integrates real-time data and automation to streamline production processes, enhancing efficiency and reducing downtime across the supply chain. Digital twin manufacturing leverages an end-to-end supply chain twin, creating a virtual replica of the entire manufacturing ecosystem to enable predictive analytics, scenario simulations, and optimized resource allocation.

Automated Model Validation

Continuous manufacturing integrates automated model validation to ensure real-time process optimization and consistent product quality, reducing variability and downtime. Digital twin manufacturing leverages automated model validation by simulating and analyzing virtual replicas of production systems, enabling predictive maintenance and faster decision-making.

Continuous Feedback Loop

Continuous Manufacturing integrates real-time data to optimize production processes, creating a dynamic feedback loop that reduces downtime and improves quality control. Digital Twin Manufacturing enhances this loop by simulating physical assets and processes virtually, enabling predictive maintenance and proactive decision-making for increased efficiency.

Intelligent Edge Manufacturing

Continuous Manufacturing integrates real-time data processing and automation to enhance production efficiency, while Digital Twin Manufacturing leverages virtual replicas of physical assets for predictive maintenance and process optimization. Intelligent Edge Manufacturing combines these approaches by deploying AI-driven analytics and machine learning directly at the edge, enabling immediate decision-making and reducing latency in smart factory environments.

Adaptive Quality Assurance

Continuous Manufacturing integrates real-time data analytics to monitor and control production parameters, enhancing adaptive quality assurance by reducing defects and variability. Digital Twin Manufacturing employs virtual replicas of physical systems to simulate and predict quality issues, enabling proactive adjustments and optimized process performance.

Data-Driven Batch Release

Continuous manufacturing leverages real-time process monitoring and integrated analytics to enable data-driven batch release, enhancing product quality and reducing cycle times. Digital twin manufacturing uses virtual replicas of production systems to simulate and optimize operations, providing predictive insights that further streamline batch release decisions through data-driven validation.

Continuous Manufacturing vs Digital Twin Manufacturing Infographic

industrydif.com

industrydif.com