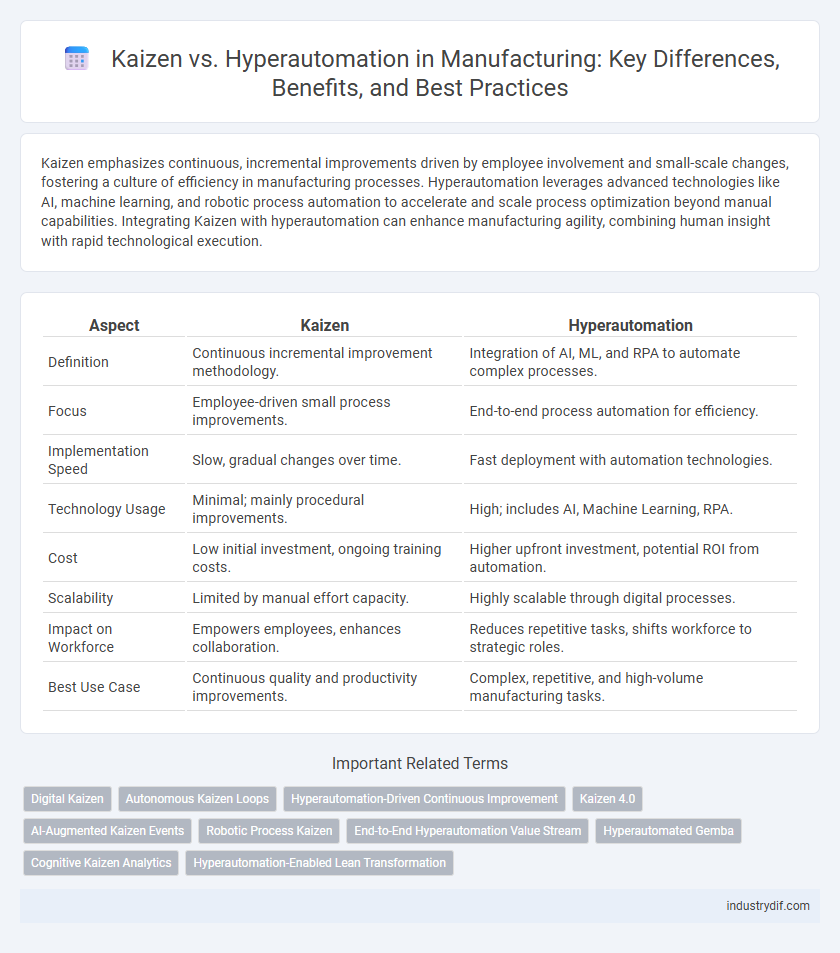

Kaizen emphasizes continuous, incremental improvements driven by employee involvement and small-scale changes, fostering a culture of efficiency in manufacturing processes. Hyperautomation leverages advanced technologies like AI, machine learning, and robotic process automation to accelerate and scale process optimization beyond manual capabilities. Integrating Kaizen with hyperautomation can enhance manufacturing agility, combining human insight with rapid technological execution.

Table of Comparison

| Aspect | Kaizen | Hyperautomation |

|---|---|---|

| Definition | Continuous incremental improvement methodology. | Integration of AI, ML, and RPA to automate complex processes. |

| Focus | Employee-driven small process improvements. | End-to-end process automation for efficiency. |

| Implementation Speed | Slow, gradual changes over time. | Fast deployment with automation technologies. |

| Technology Usage | Minimal; mainly procedural improvements. | High; includes AI, Machine Learning, RPA. |

| Cost | Low initial investment, ongoing training costs. | Higher upfront investment, potential ROI from automation. |

| Scalability | Limited by manual effort capacity. | Highly scalable through digital processes. |

| Impact on Workforce | Empowers employees, enhances collaboration. | Reduces repetitive tasks, shifts workforce to strategic roles. |

| Best Use Case | Continuous quality and productivity improvements. | Complex, repetitive, and high-volume manufacturing tasks. |

Introduction to Kaizen and Hyperautomation

Kaizen is a continuous improvement methodology focused on incremental changes to enhance manufacturing processes, quality, and efficiency through employee involvement and systematic problem-solving. Hyperautomation integrates advanced technologies such as artificial intelligence, machine learning, and robotic process automation to streamline complex manufacturing workflows and drive end-to-end automation. Both approaches aim to optimize production, with Kaizen emphasizing gradual human-centered improvements and Hyperautomation leveraging digital transformation to accelerate operational performance.

Defining Kaizen: Principles and Practices

Kaizen in manufacturing emphasizes continuous, incremental improvements driven by employee involvement and standardized work practices to enhance efficiency and reduce waste. Its core principles include teamwork, personal discipline, improved morale, quality circles, and suggestions for small, ongoing changes. This approach fosters a culture of constant enhancement by focusing on process optimization through human-centric strategies rather than relying solely on technology.

Understanding Hyperautomation in Manufacturing

Hyperautomation in manufacturing leverages advanced technologies such as AI, machine learning, and robotic process automation (RPA) to streamline production processes and enhance operational efficiency beyond traditional Kaizen continuous improvement methods. Unlike Kaizen's gradual, incremental improvements, hyperautomation targets end-to-end automation of complex workflows, enabling real-time data analysis and faster decision-making on the factory floor. This integration of intelligent automation drives significant productivity gains, reduces human error, and accelerates adaptation to changing market demands.

Key Differences Between Kaizen and Hyperautomation

Kaizen emphasizes continuous incremental improvements through employee involvement and small changes in manufacturing processes, fostering a culture of collaboration and quality enhancement. Hyperautomation integrates advanced technologies like artificial intelligence, robotic process automation, and machine learning to automate complex, repetitive tasks, driving efficiency and scalability at a higher pace. The key difference lies in Kaizen's human-centric, gradual approach versus Hyperautomation's technology-driven, rapid transformation of manufacturing workflows.

Benefits of Kaizen Implementation

Kaizen implementation in manufacturing drives continuous incremental improvements, enhancing productivity and reducing waste through employee-driven suggestions. This approach fosters a culture of quality and teamwork, leading to higher operational efficiency and lower downtime. Consistent Kaizen practices result in optimized processes that improve product quality and increase overall customer satisfaction.

Advantages of Hyperautomation Adoption

Hyperautomation in manufacturing significantly enhances operational efficiency by combining AI, machine learning, and robotic process automation to streamline complex workflows and reduce manual errors. It enables real-time data analysis and predictive maintenance, minimizing downtime and optimizing resource allocation. The scalability and flexibility of hyperautomation systems allow manufacturers to quickly adapt to market changes and improve overall productivity beyond traditional Kaizen methods.

Challenges in Integrating Kaizen vs Hyperautomation

Integrating Kaizen's continuous improvement culture with Hyperautomation's advanced AI-driven processes faces challenges such as aligning human-centric incremental changes with rapid technological transformations. Resistance to change and skill gaps among employees often hinder the seamless adoption of automated workflows alongside Kaizen practices. Data integration complexities and maintaining operational flexibility further complicate harmonizing these approaches in manufacturing environments.

Case Studies: Kaizen and Hyperautomation in Action

Case studies reveal that Kaizen implementation in manufacturing plants leads to incremental process improvements, resulting in a 20% increase in productivity and a 15% reduction in waste over 12 months. Hyperautomation deployment in similar environments demonstrates faster ROI through AI-driven workflows and robotic process automation, cutting cycle times by 40% and enhancing quality control accuracy by 25%. Comparative analyses highlight that blending Kaizen's continuous improvement ethos with hyperautomation tools generates synergistic effects, driving innovation and operational excellence.

Choosing the Right Approach for Your Manufacturing Needs

Kaizen emphasizes continuous, incremental improvements driven by employee engagement and process refinement, ideal for fostering a culture of quality and reducing waste in manufacturing. Hyperautomation leverages advanced technologies like AI, machine learning, and robotic process automation to accelerate production efficiency and optimize complex workflows. Selecting the right approach depends on your factory's readiness for digital transformation, the scale of operational challenges, and the desired speed of innovation in manufacturing processes.

The Future of Continuous Improvement in Manufacturing

Kaizen emphasizes incremental, human-driven process improvements through employee engagement and small changes, while hyperautomation leverages AI, machine learning, and robotic process automation to accelerate and scale operational enhancements. The future of continuous improvement in manufacturing integrates Kaizen's culture of ongoing, collaborative refinement with hyperautomation's capacity for rapid data analysis and workflow automation. This synergy drives unprecedented efficiency, quality, and adaptability in production environments.

Related Important Terms

Digital Kaizen

Digital Kaizen enhances continuous improvement in manufacturing by integrating real-time data analytics and IoT sensors, enabling incremental process optimizations that reduce waste and increase efficiency. Hyperautomation leverages advanced AI and machine learning to automate complex workflows end-to-end, but Digital Kaizen remains critical for sustaining employee-driven innovation and fine-tuning automated systems.

Autonomous Kaizen Loops

Autonomous Kaizen Loops integrate Kaizen's continuous improvement principles with hyperautomation technologies, enabling real-time data analysis and automated decision-making to optimize manufacturing processes. This fusion accelerates efficiency gains by continuously identifying, executing, and validating process enhancements without human intervention.

Hyperautomation-Driven Continuous Improvement

Hyperautomation-driven continuous improvement in manufacturing leverages advanced technologies like AI, machine learning, and robotic process automation to streamline production, reduce errors, and enhance operational efficiency beyond traditional Kaizen methods. This approach enables real-time data analysis and adaptive process optimization, fostering rapid innovation and sustained competitive advantage in complex manufacturing environments.

Kaizen 4.0

Kaizen 4.0 integrates continuous improvement principles with Industry 4.0 technologies like IoT, AI, and data analytics to enhance manufacturing efficiency and reduce waste. Unlike hyperautomation, which emphasizes end-to-end process automation, Kaizen 4.0 focuses on empowering employees to drive incremental innovations supported by smart digital tools.

AI-Augmented Kaizen Events

AI-augmented Kaizen events leverage machine learning algorithms to identify inefficiencies and optimize processes faster than traditional Kaizen methods. Integrating hyperautomation tools such as AI-driven analytics and robotic process automation enhances real-time decision-making, enabling continuous improvement in manufacturing workflows.

Robotic Process Kaizen

Robotic Process Kaizen integrates continuous, incremental improvements with robotic process automation (RPA) to enhance efficiency and reduce errors in manufacturing workflows, driving sustained productivity gains. Hyperautomation, while broader in scope by incorporating AI, machine learning, and advanced analytics, complements Kaizen principles by automating complex processes beyond traditional RPA capabilities.

End-to-End Hyperautomation Value Stream

Kaizen drives incremental improvements through continuous employee engagement and process refinement, while End-to-End Hyperautomation integrates advanced technologies like AI, RPA, and IoT to automate and optimize the entire manufacturing value stream, achieving higher scalability and efficiency. Leveraging Hyperautomation in manufacturing enhances real-time data analytics, reduces manual intervention across workflows, and accelerates decision-making, delivering a transformative impact beyond traditional Kaizen methods.

Hyperautomated Gemba

Hyperautomated Gemba integrates advanced AI, IoT sensors, and real-time data analytics on the manufacturing floor to optimize workflows and minimize downtime, surpassing traditional Kaizen's manual continuous improvement methods. This approach enables dynamic decision-making and predictive maintenance, driving significant gains in operational efficiency and quality control.

Cognitive Kaizen Analytics

Cognitive Kaizen Analytics enhances traditional Kaizen methodologies by integrating AI-driven data analysis to identify inefficiencies and optimize manufacturing processes in real-time. Hyperautomation extends this by automating complex decision-making workflows, but Cognitive Kaizen Analytics uniquely focuses on continuous, incremental improvements through cognitive insights and employee-driven innovation.

Hyperautomation-Enabled Lean Transformation

Hyperautomation-enabled lean transformation in manufacturing leverages AI, machine learning, and robotic process automation to streamline operations, reduce waste, and enhance real-time decision-making. This approach outperforms traditional Kaizen by accelerating continuous improvement cycles and driving scalable efficiency across complex production systems.

Kaizen vs Hyperautomation Infographic

industrydif.com

industrydif.com