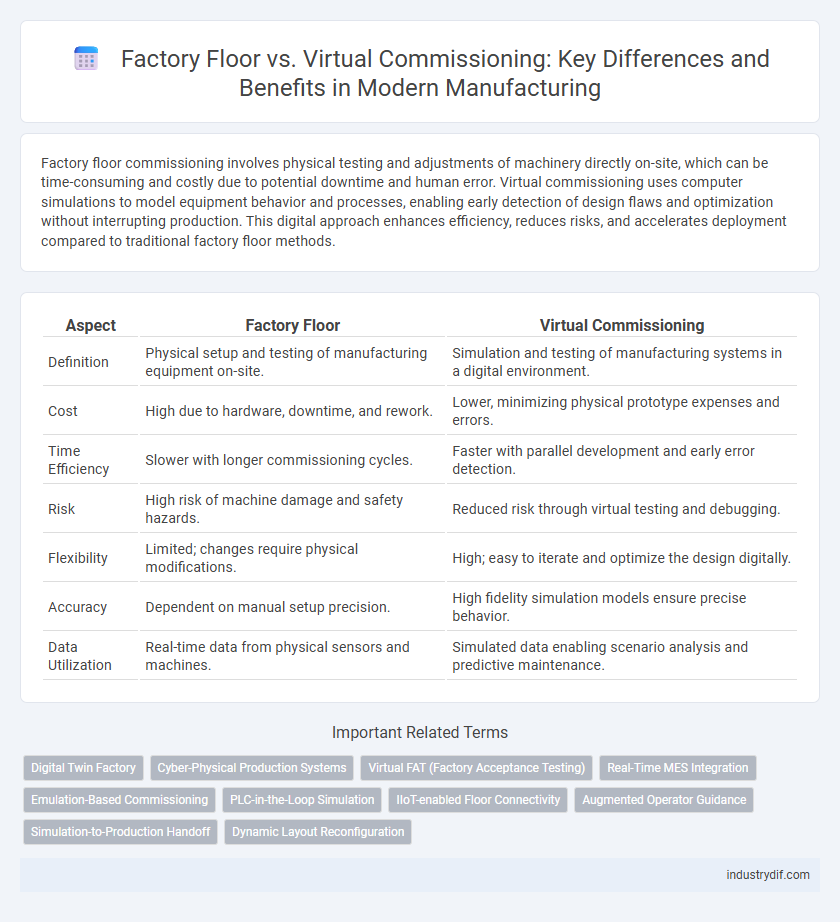

Factory floor commissioning involves physical testing and adjustments of machinery directly on-site, which can be time-consuming and costly due to potential downtime and human error. Virtual commissioning uses computer simulations to model equipment behavior and processes, enabling early detection of design flaws and optimization without interrupting production. This digital approach enhances efficiency, reduces risks, and accelerates deployment compared to traditional factory floor methods.

Table of Comparison

| Aspect | Factory Floor | Virtual Commissioning |

|---|---|---|

| Definition | Physical setup and testing of manufacturing equipment on-site. | Simulation and testing of manufacturing systems in a digital environment. |

| Cost | High due to hardware, downtime, and rework. | Lower, minimizing physical prototype expenses and errors. |

| Time Efficiency | Slower with longer commissioning cycles. | Faster with parallel development and early error detection. |

| Risk | High risk of machine damage and safety hazards. | Reduced risk through virtual testing and debugging. |

| Flexibility | Limited; changes require physical modifications. | High; easy to iterate and optimize the design digitally. |

| Accuracy | Dependent on manual setup precision. | High fidelity simulation models ensure precise behavior. |

| Data Utilization | Real-time data from physical sensors and machines. | Simulated data enabling scenario analysis and predictive maintenance. |

Factory Floor: Definition and Key Concepts

The factory floor refers to the physical space within a manufacturing facility where production processes occur, encompassing machinery, workers, and workflows integral to product assembly and quality control. Key concepts include lean manufacturing principles, real-time process monitoring, and equipment layout optimization to enhance productivity and reduce waste. Understanding factory floor dynamics is crucial for effective resource allocation, maintaining safety standards, and optimizing operational efficiency.

What is Virtual Commissioning?

Virtual commissioning is a digital process that uses simulation software to replicate and test manufacturing systems before physical installation on the factory floor. It enables engineers to identify design flaws, optimize workflows, and validate control logic, significantly reducing commissioning time and costs. By integrating virtual commissioning, manufacturers enhance production efficiency and minimize downtime during system startup.

Differences Between Factory Floor and Virtual Commissioning

Factory floor commissioning involves physical testing and validation of machinery directly on-site, ensuring real-world operational conditions and immediate troubleshooting. Virtual commissioning uses digital twins and simulation software to model and test equipment behavior in a virtual environment, reducing downtime and early detection of design flaws. The key difference lies in virtual commissioning's ability to anticipate issues pre-installation, enhancing efficiency compared to the reactive adjustments required on the factory floor.

Advantages of Traditional Factory Floor Setup

Traditional factory floor setups offer direct, hands-on control, enabling immediate troubleshooting and real-time adjustments to machinery and processes. This physical environment facilitates intuitive communication among operators and engineers, enhancing collaboration and reducing the risk of misinterpretation. The tangible presence of equipment allows for practical training and direct monitoring of production quality, ensuring consistent output and operational reliability.

Benefits of Virtual Commissioning in Manufacturing

Virtual commissioning in manufacturing reduces downtime by enabling thorough testing and validation of control systems before physical installation. It enhances accuracy and efficiency through early detection of design flaws and process optimization. The approach also lowers costs by minimizing on-site errors and facilitating faster project completion.

Integration of Digital Twins in Virtual Commissioning

Integration of digital twins in virtual commissioning enhances factory floor operations by enabling precise simulation and optimization of manufacturing processes before physical deployment. Digital twins create real-time, data-driven replicas of equipment and systems, facilitating early detection of potential issues and reducing downtime. This approach accelerates commissioning timelines while improving accuracy and operational efficiency in complex manufacturing environments.

Impact on Production Efficiency and Downtime

Factory floor commissioning often leads to extended downtime and production inefficiencies due to the need for physical troubleshooting and adjustments during equipment installation. Virtual commissioning leverages digital twins and simulation models to identify and resolve issues before physical deployment, significantly reducing downtime and enhancing overall production efficiency. Implementing virtual commissioning can accelerate time-to-market and optimize resource allocation by minimizing on-site errors and unexpected stoppages.

Cost Implications: Factory Floor vs Virtual Commissioning

Factory floor commissioning incurs higher costs due to physical equipment setup, labor-intensive troubleshooting, and prolonged downtime impacting production schedules. Virtual commissioning significantly lowers expenses by enabling simulation-based testing, early error detection, and process optimization without halting real-world operations. Companies leveraging virtual commissioning report up to 30% reduction in commissioning costs and accelerated time-to-market for manufacturing systems.

Challenges and Limitations of Both Approaches

Factory floor commissioning faces challenges such as downtime, safety risks, and limited flexibility due to physical constraints and equipment wear. Virtual commissioning offers improved risk mitigation and early error detection but is limited by the accuracy of digital twins and requires high computational resources. Both approaches struggle with integration complexities and may encounter issues related to real-time data synchronization and system validation.

Future Trends in Manufacturing Commissioning Technologies

Factory floor commissioning relies heavily on physical prototypes and manual processes, which can delay production timelines and increase costs. Virtual commissioning leverages digital twins and simulation software to streamline equipment testing, enabling faster iterations and early error detection. Future trends indicate a shift towards integrating AI-driven analytics and IoT connectivity to create adaptive, predictive commissioning systems that optimize manufacturing efficiency.

Related Important Terms

Digital Twin Factory

Digital Twin Factory enables virtual commissioning by creating a precise digital replica of the factory floor, allowing engineers to simulate, test, and optimize manufacturing processes before physical implementation. This approach reduces downtime, minimizes errors, and accelerates production ramp-up compared to traditional factory floor commissioning methods.

Cyber-Physical Production Systems

Factory floor operations rely heavily on physical machinery and real-time human intervention within Cyber-Physical Production Systems (CPPS), while virtual commissioning enables early testing and optimization of these systems through digital twins, reducing downtime and costly errors. Integrating CPPS with virtual commissioning accelerates production scalability by simulating complex workflows, improving system responsiveness, and enhancing predictive maintenance capabilities.

Virtual FAT (Factory Acceptance Testing)

Virtual FAT (Factory Acceptance Testing) enables manufacturers to simulate and validate factory floor processes digitally, reducing physical prototyping costs and accelerating project timelines. This approach enhances early detection of design flaws and integration issues, ensuring smoother commissioning and minimizing disruptions during actual factory floor implementation.

Real-Time MES Integration

Factory floor operations rely heavily on real-time MES integration to monitor production efficiency and ensure quality control, enabling immediate adjustments based on live data streams. Virtual commissioning leverages simulated environments for pre-validated MES interactions, reducing downtime and accelerating deployment by integrating real-time data feedback before physical setup.

Emulation-Based Commissioning

Emulation-based commissioning leverages digital twins of factory floor equipment to simulate and validate control logic before physical deployment, reducing downtime and costly errors. This virtual commissioning approach enhances manufacturing efficiency by enabling early detection of faults and optimization of system integration in a risk-free environment.

PLC-in-the-Loop Simulation

PLC-in-the-Loop simulation enhances Virtual Commissioning by integrating programmable logic controllers directly into the digital model, enabling real-time testing and validation of control algorithms before physical deployment on the factory floor. This approach reduces commissioning time and minimizes costly errors by simulating actual plant behavior and control logic interactions in a virtual environment.

IIoT-enabled Floor Connectivity

IIoT-enabled floor connectivity transforms traditional factory floors by integrating real-time data from smart sensors and machines, enhancing operational efficiency and predictive maintenance. Virtual commissioning complements this by simulating production processes digitally, reducing downtime and optimizing configurations before physical deployment.

Augmented Operator Guidance

Augmented Operator Guidance enhances Factory Floor operations by overlaying real-time data and instructions, enabling immediate troubleshooting and efficiency improvements during physical manufacturing processes. Virtual Commissioning leverages digital twins to simulate production environments, allowing operators to train and optimize workflows virtually before deploying on the actual factory floor, reducing errors and downtime.

Simulation-to-Production Handoff

Factory floor processes rely on real-time adjustments and physical feedback, whereas virtual commissioning enables early detection of design flaws through digital twin simulations. Simulation-to-production handoff is optimized by seamlessly transferring validated virtual models to physical systems, reducing downtime and enhancing production accuracy.

Dynamic Layout Reconfiguration

Factory floor processes rely heavily on physical equipment rearrangement for layout changes, causing downtime and increased labor costs, whereas virtual commissioning uses digital twins to simulate and optimize dynamic layout reconfiguration without interrupting production. Implementing virtual commissioning enables manufacturers to test multiple scenarios rapidly, reduce errors, and accelerate deployment timelines while maintaining operational efficiency on the factory floor.

Factory Floor vs Virtual Commissioning Infographic

industrydif.com

industrydif.com