Industrial robotics offer high-speed, precision automation designed for repetitive, heavy-duty tasks in manufacturing, enhancing productivity and reducing labor costs. Collaborative robots (cobots) are engineered to work safely alongside human operators, providing flexibility and ease of programming for tasks requiring adaptability and close human-robot interaction. Both technologies drive efficiency but differ in application scope, with industrial robots suited for large-scale production and cobots excelling in environments demanding human collaboration.

Table of Comparison

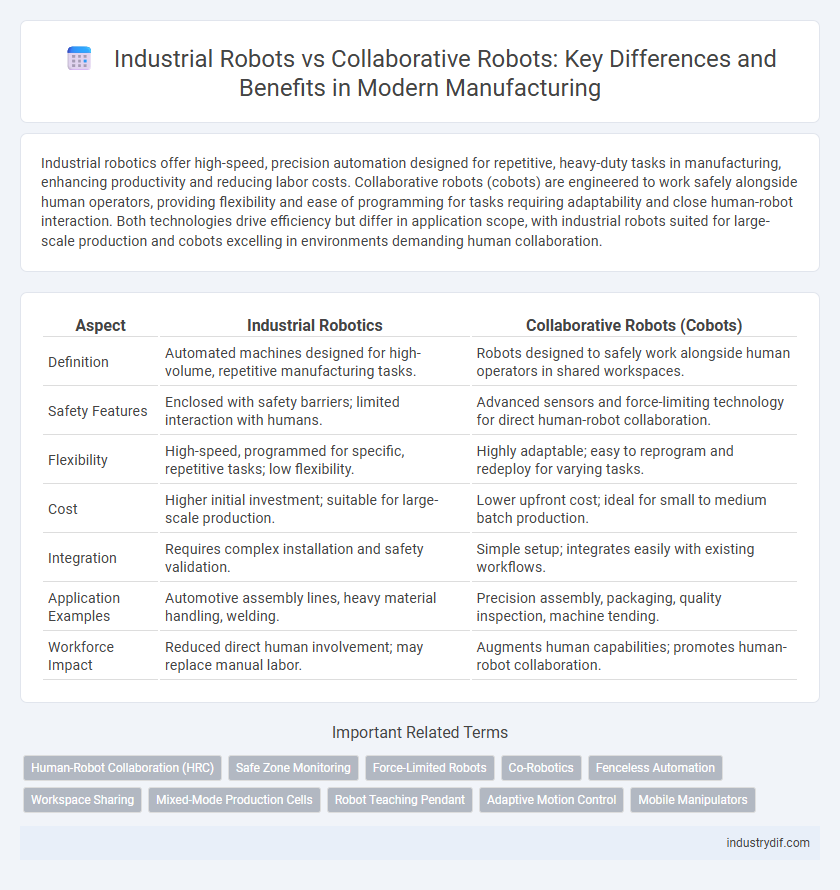

| Aspect | Industrial Robotics | Collaborative Robots (Cobots) |

|---|---|---|

| Definition | Automated machines designed for high-volume, repetitive manufacturing tasks. | Robots designed to safely work alongside human operators in shared workspaces. |

| Safety Features | Enclosed with safety barriers; limited interaction with humans. | Advanced sensors and force-limiting technology for direct human-robot collaboration. |

| Flexibility | High-speed, programmed for specific, repetitive tasks; low flexibility. | Highly adaptable; easy to reprogram and redeploy for varying tasks. |

| Cost | Higher initial investment; suitable for large-scale production. | Lower upfront cost; ideal for small to medium batch production. |

| Integration | Requires complex installation and safety validation. | Simple setup; integrates easily with existing workflows. |

| Application Examples | Automotive assembly lines, heavy material handling, welding. | Precision assembly, packaging, quality inspection, machine tending. |

| Workforce Impact | Reduced direct human involvement; may replace manual labor. | Augments human capabilities; promotes human-robot collaboration. |

Introduction to Industrial Robotics and Collaborative Robots

Industrial robotics involves automated machines designed to perform repetitive, high-precision tasks in manufacturing environments, often operating in isolated areas for safety. Collaborative robots, or cobots, are engineered to work safely alongside human operators, enhancing flexibility and productivity on assembly lines. Both technologies leverage advanced sensors and AI algorithms to optimize manufacturing processes and reduce operational costs.

Key Differences Between Industrial and Collaborative Robots

Industrial robotics excel in high-speed, heavy-duty tasks with precise repeatability in controlled environments, handling complex automation on assembly lines. Collaborative robots, or cobots, prioritize safety features and ease of use, enabling direct human interaction and flexible deployment without extensive safety barriers. Key differences include payload capacity, operating speed, programming complexity, and integration for collaborative vs. isolated applications in manufacturing.

Core Applications in Modern Manufacturing

Industrial robotics excel in high-volume, repetitive tasks such as welding, painting, and material handling, delivering precision and speed in automotive and electronics manufacturing. Collaborative robots, or cobots, are designed for direct human interaction, enhancing assembly, quality inspection, and machine tending processes by increasing flexibility and safety. Both technologies optimize production efficiency but serve distinct roles: industrial robots handle heavy-duty, continuous operations, while cobots adapt to dynamic environments requiring human-robot collaboration.

Safety Standards and Human-Robot Interaction

Industrial robotics emphasize stringent safety standards with physical barriers and safety cages to isolate robots from workers, minimizing human-robot interaction risks. Collaborative robots (cobots) integrate advanced sensors, force-limiting features, and real-time monitoring to enable safe, direct interaction with humans on shared workspaces. Compliance with ISO 10218 and ISO/TS 15066 standards is critical for both, guiding risk assessment and safe deployment in manufacturing environments.

Flexibility and Programming Ease

Industrial robotics excel in high-speed, repetitive tasks with robust, pre-programmed precision but often require specialized programming skills, making them less flexible for frequent changes. Collaborative robots (cobots) offer greater flexibility through intuitive programming interfaces, allowing operators without advanced coding expertise to quickly adapt tasks for varied production needs. This ease of programming combined with safe human-robot interaction makes cobots ideal for dynamic manufacturing environments seeking rapid deployment and customization.

Cost Analysis and ROI Considerations

Industrial robotics typically involve higher upfront costs due to complex programming and heavy-duty design, impacting initial capital expenditure. Collaborative robots (cobots) offer lower installation and maintenance costs, enhancing ROI through faster deployment and flexible integration within existing workflows. Cost analysis should consider total cost of ownership, including downtime reduction, worker safety improvements, and potential productivity gains achieved by each robot type.

Integration Challenges in Production Lines

Industrial robotics often require complex programming and specialized infrastructure, making integration into existing production lines time-consuming and costly. Collaborative robots (cobots) offer easier deployment and greater flexibility but pose challenges in ensuring safety and maintaining seamless communication with legacy systems. Both types demand careful alignment with production workflows to minimize downtime and optimize operational efficiency.

Productivity and Efficiency Comparisons

Industrial robotics deliver high-speed precision and can operate continuously in hazardous environments, significantly boosting productivity in large-scale manufacturing. Collaborative robots (cobots) enhance efficiency by working safely alongside humans, enabling flexible automation and reducing setup times for varied tasks. While industrial robots excel in volume and repeatability, cobots offer superior adaptability and ease of integration, optimizing overall operational efficiency.

Maintenance and Lifecycle Management

Industrial robotics requires specialized maintenance teams due to complex programming and high payload capacities, often involving scheduled overhauls to ensure peak performance over extended lifecycles. Collaborative robots (cobots) feature simplified maintenance protocols with self-diagnostic systems, reducing downtime and extending lifecycle through adaptive software updates. Lifecycle management in industrial settings increasingly integrates IoT sensors and predictive analytics to optimize both industrial robots and cobots for longevity and operational efficiency.

Future Trends in Robotics for Manufacturing

Industrial robotics in manufacturing are increasingly integrating advanced AI and machine learning to enhance precision and operational efficiency, while collaborative robots (cobots) emphasize safe human-robot interaction and adaptability on the production line. Future trends indicate a significant rise in the deployment of autonomous mobile robots (AMRs) combined with IoT connectivity for real-time data exchange and predictive maintenance. The shift towards smart factories will drive the convergence of industrial robots and cobots, optimizing workflows through enhanced sensor technology and adaptive automation systems.

Related Important Terms

Human-Robot Collaboration (HRC)

Industrial robotics primarily operate in isolated environments designed for high-speed, repetitive tasks, whereas collaborative robots (cobots) are engineered for safe, direct interaction with human operators, enabling seamless Human-Robot Collaboration (HRC) on manufacturing floors. HRC enhances productivity and flexibility by combining human dexterity and decision-making with robotic precision and endurance, optimizing assembly lines and quality control processes.

Safe Zone Monitoring

Safe zone monitoring in industrial robotics relies on fixed barriers and sensors to prevent human entry in hazardous areas, ensuring high safety standards in large-scale manufacturing environments. Collaborative robots integrate advanced proximity sensors and real-time monitoring systems, enabling dynamic safe zone adjustments that allow humans and robots to work closely without compromising safety.

Force-Limited Robots

Force-limited robots, a key category within collaborative robots (cobots), feature advanced sensors that limit the amount of force they exert, ensuring safe interaction with human workers on manufacturing floors. Unlike traditional industrial robots designed for high-speed, repetitive tasks with physical barriers, force-limited robots enable flexible automation by combining precision with enhanced safety protocols.

Co-Robotics

Co-robotics in manufacturing integrates collaborative robots (cobots) designed to work safely alongside human operators, enhancing productivity and flexibility on assembly lines. Unlike traditional industrial robots, which operate in isolated environments, cobots feature advanced sensors and AI-driven precision, enabling seamless human-robot interaction and real-time task adaptation.

Fenceless Automation

Industrial robotics typically operate within safeguarded environments using physical barriers, whereas collaborative robots (cobots) enable fenceless automation by safely working alongside human operators without the need for extensive safety fencing. Advances in sensor technology and real-time monitoring empower fenceless automation, increasing workspace efficiency and flexibility in manufacturing settings.

Workspace Sharing

Industrial robotics operate in segregated workspaces with safety barriers to prevent human-robot interaction, maximizing speed and precision but limiting flexibility. Collaborative robots (cobots) are designed for shared workspaces, equipped with advanced sensors and force feedback systems to safely work alongside human operators, enhancing efficiency and adaptability in manufacturing environments.

Mixed-Mode Production Cells

Mixed-mode production cells integrate industrial robotics and collaborative robots to optimize manufacturing efficiency by combining high-speed automation with flexible, human-robot interaction. Industrial robots deliver precision and endurance for repetitive tasks, while collaborative robots enhance adaptability and safety, enabling seamless workflow in dynamic production environments.

Robot Teaching Pendant

Robot teaching pendants for industrial robotics provide advanced programming capabilities with high precision controls designed for complex automation tasks in manufacturing environments. Collaborative robots utilize simplified, user-friendly teaching pendants that enable operators without extensive programming skills to quickly train robots for flexible, safe interactions on shared workspaces.

Adaptive Motion Control

Industrial robotics utilize advanced adaptive motion control to optimize high-speed, repetitive tasks with precision and stability in large-scale manufacturing environments. Collaborative robots integrate adaptive motion control for safe, flexible interactions with human operators, enabling seamless task sharing and real-time adjustments in dynamic production settings.

Mobile Manipulators

Mobile manipulators integrate advanced industrial robotics capabilities with collaborative robot safety features, enhancing flexibility and precision in manufacturing environments. Their ability to navigate dynamic workspaces autonomously while performing complex tasks optimizes production efficiency and reduces human-robot interaction risks.

Industrial Robotics vs Collaborative Robots Infographic

industrydif.com

industrydif.com