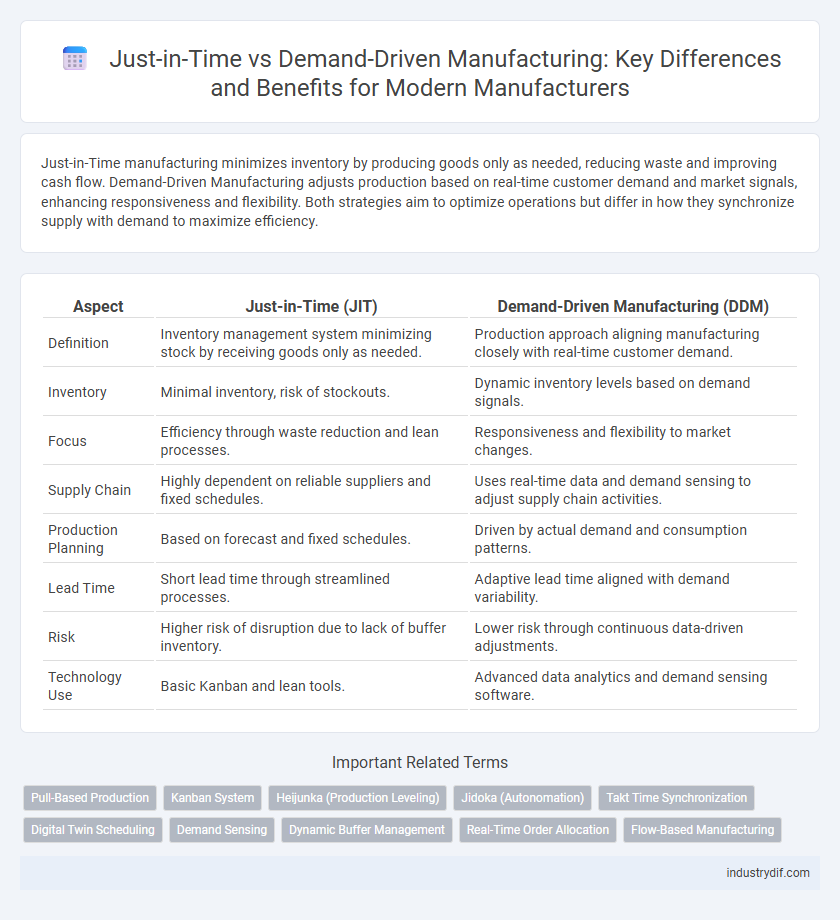

Just-in-Time manufacturing minimizes inventory by producing goods only as needed, reducing waste and improving cash flow. Demand-Driven Manufacturing adjusts production based on real-time customer demand and market signals, enhancing responsiveness and flexibility. Both strategies aim to optimize operations but differ in how they synchronize supply with demand to maximize efficiency.

Table of Comparison

| Aspect | Just-in-Time (JIT) | Demand-Driven Manufacturing (DDM) |

|---|---|---|

| Definition | Inventory management system minimizing stock by receiving goods only as needed. | Production approach aligning manufacturing closely with real-time customer demand. |

| Inventory | Minimal inventory, risk of stockouts. | Dynamic inventory levels based on demand signals. |

| Focus | Efficiency through waste reduction and lean processes. | Responsiveness and flexibility to market changes. |

| Supply Chain | Highly dependent on reliable suppliers and fixed schedules. | Uses real-time data and demand sensing to adjust supply chain activities. |

| Production Planning | Based on forecast and fixed schedules. | Driven by actual demand and consumption patterns. |

| Lead Time | Short lead time through streamlined processes. | Adaptive lead time aligned with demand variability. |

| Risk | Higher risk of disruption due to lack of buffer inventory. | Lower risk through continuous data-driven adjustments. |

| Technology Use | Basic Kanban and lean tools. | Advanced data analytics and demand sensing software. |

Overview of Just-in-Time (JIT) Manufacturing

Just-in-Time (JIT) Manufacturing minimizes inventory by producing goods solely in response to actual demand, reducing waste and improving efficiency. It relies on precise scheduling, strong supplier relationships, and continuous improvement to synchronize production with customer orders. JIT enhances cash flow and decreases storage costs but requires high reliability and agility within the supply chain.

Fundamentals of Demand-Driven Manufacturing

Demand-Driven Manufacturing centers on aligning production closely with real-time customer demand, utilizing dynamic inventory signals and advanced analytics to optimize workflow and reduce waste. Unlike Just-in-Time, which primarily focuses on minimizing inventory through scheduled deliveries, Demand-Driven Manufacturing adapts quickly to market fluctuations by synchronizing supply chain activities with actual consumption patterns. This approach enhances responsiveness, improves service levels, and supports more sustainable resource utilization in manufacturing operations.

Key Differences Between JIT and Demand-Driven Approaches

Just-in-Time (JIT) manufacturing emphasizes minimizing inventory by producing goods only as they are needed, focusing on efficiency and waste reduction through tightly controlled production schedules. Demand-Driven Manufacturing prioritizes real-time customer demand signals to dynamically adjust production and inventory levels, enhancing responsiveness and flexibility in supply chain management. The key differences lie in JIT's reliance on forecast-driven pull systems versus Demand-Driven's real-time demand sensing technology for adaptive production planning.

Inventory Management: JIT vs Demand-Driven

Just-in-Time (JIT) manufacturing minimizes inventory by receiving materials only as needed, reducing carrying costs but increasing vulnerability to supply chain disruptions. Demand-Driven Manufacturing uses real-time demand data to adjust inventory levels dynamically, balancing lean inventory with responsiveness and reducing stockouts. Effective inventory management in demand-driven systems relies on advanced analytics and flexible replenishment strategies to optimize stock levels and meet fluctuating customer demands.

Impact on Supply Chain Efficiency

Just-in-Time (JIT) manufacturing minimizes inventory by synchronizing production schedules with demand, reducing holding costs but increasing vulnerability to supply chain disruptions. Demand-Driven Manufacturing (DDM) enhances supply chain efficiency by using real-time data and demand signals to adjust production dynamically, improving responsiveness and minimizing waste. Integrating DDM strategies often results in more agile supply chains with reduced lead times and better alignment with customer requirements compared to traditional JIT approaches.

Technology Integration in Modern Manufacturing

Technology integration in modern manufacturing enables seamless synchronization of Just-in-Time (JIT) processes by utilizing IoT sensors, real-time data analytics, and automated inventory management systems to minimize waste and reduce lead times. Demand-Driven Manufacturing leverages advanced AI algorithms and cloud-based platforms that analyze market demand signals and adapt production schedules dynamically, enhancing responsiveness and flexibility. Both approaches benefit from digital twins and smart factory technologies that optimize resource allocation and improve decision-making accuracy.

Risk Management and Resilience

Just-in-Time manufacturing minimizes inventory costs by synchronizing production closely with demand, but risks supply chain disruptions due to its limited buffer stock. Demand-Driven Manufacturing enhances risk management and resilience by using real-time data to adjust production dynamically, allowing quicker responses to market fluctuations and unexpected disruptions. Firms adopting demand-driven strategies better withstand volatility through flexible workflows and diversified supplier networks.

Flexibility and Scalability in Production

Just-in-Time (JIT) manufacturing prioritizes minimizing inventory and streamlining production schedules to reduce waste, but it often lacks flexibility when demand fluctuations occur. Demand-Driven Manufacturing (DDM) enhances scalability by closely aligning production with real-time customer demand signals, allowing rapid adjustments in output volume and product mix. This responsiveness enables manufacturers to better manage supply chain disruptions and variable market conditions compared to the rigid scheduling of JIT systems.

Cost Implications and Profitability

Just-in-Time (JIT) manufacturing minimizes inventory holding costs by synchronizing production with demand, thereby reducing waste and lowering operational expenses. Demand-Driven Manufacturing (DDM) enhances profitability by using real-time market data and adaptive supply chain strategies to respond quickly to fluctuating customer needs, preventing stockouts and excess inventory. While JIT focuses on cost efficiency through lean inventory, DDM drives higher profit margins by aligning production directly with consumer demand patterns.

Future Trends in Manufacturing Methodologies

Future trends in manufacturing emphasize a shift from traditional Just-in-Time (JIT) to Demand-Driven Manufacturing (DDM) to enhance supply chain agility and responsiveness. Advanced technologies such as artificial intelligence, machine learning, and IoT enable real-time data analytics, optimizing inventory levels and production scheduling based on actual customer demand. This evolution supports sustainability goals by reducing waste and improving overall operational efficiency in smart factories.

Related Important Terms

Pull-Based Production

Pull-based production in Just-in-Time (JIT) manufacturing minimizes inventory by producing goods only as customer orders trigger demand, enhancing efficiency and reducing waste. In contrast, Demand-Driven Manufacturing integrates real-time data analytics and supply chain synchronization to dynamically adjust production schedules, further optimizing responsiveness and resource allocation.

Kanban System

The Kanban system in manufacturing optimizes inventory control by visually signaling production needs, aligning closely with Just-in-Time (JIT) principles to minimize waste and reduce lead times. Unlike traditional JIT, demand-driven manufacturing leverages real-time data and Kanban cards to dynamically adjust workflows, enhancing responsiveness to customer demand fluctuations.

Heijunka (Production Leveling)

Heijunka, a core principle in Lean Manufacturing, optimizes production leveling by distributing manufacturing orders evenly, reducing inventory waste and minimizing lead times in Just-in-Time (JIT) systems. Demand-Driven Manufacturing leverages advanced analytics and real-time data to dynamically adjust Heijunka schedules, enhancing responsiveness and aligning production closely with fluctuating customer demand.

Jidoka (Autonomation)

Jidoka, a core principle in Just-in-Time manufacturing, empowers machines and operators to detect abnormalities and halt production immediately, ensuring high-quality output with minimal waste. Unlike traditional Demand-Driven Manufacturing, which focuses on reacting to market demand fluctuations, Jidoka emphasizes built-in automation and human intervention to prevent defects and optimize efficiency at every production stage.

Takt Time Synchronization

Takt Time Synchronization in Just-in-Time manufacturing aligns production pace precisely with customer demand intervals, minimizing inventory and reducing lead times. In Demand-Driven Manufacturing, Takt Time adapts dynamically to real-time order fluctuations, enhancing responsiveness and optimizing resource allocation.

Digital Twin Scheduling

Digital Twin Scheduling enhances Demand-Driven Manufacturing by creating real-time virtual replicas of production processes, enabling precise adjustments to meet fluctuating demand and reduce waste. Unlike Just-in-Time systems that rely on fixed schedules, digital twins provide continuous data analytics for dynamic resource allocation, improving efficiency and responsiveness in manufacturing operations.

Demand Sensing

Demand sensing leverages real-time data analytics and machine learning to improve forecast accuracy by capturing short-term market demand fluctuations, thereby enhancing production responsiveness. Unlike traditional just-in-time manufacturing, demand-driven manufacturing integrates demand sensing to minimize inventory costs and reduce lead times while increasing supply chain agility.

Dynamic Buffer Management

Dynamic Buffer Management in Demand-Driven Manufacturing enhances inventory control by continuously adjusting buffer sizes based on real-time demand and supply variability, reducing stockouts and excess inventory more effectively than traditional Just-in-Time systems. This adaptive approach improves production flow and responsiveness, enabling manufacturers to better align output with fluctuating market conditions.

Real-Time Order Allocation

Real-time order allocation in demand-driven manufacturing optimizes inventory levels by synchronizing production schedules directly with actual customer demand, reducing waste compared to traditional Just-in-Time systems. Advanced analytics and IoT integration enhance responsiveness, enabling manufacturers to dynamically adjust resources and prioritize orders for increased efficiency and minimal lead times.

Flow-Based Manufacturing

Flow-based manufacturing, a key component of demand-driven manufacturing, optimizes production by continuously synchronizing workflows with real-time customer demand, minimizing inventory and lead times. Just-in-Time (JIT) emphasizes strict inventory reduction and timely supply delivery, but flow-based manufacturing enhances responsiveness and flexibility by integrating adaptive production flows and dynamic resource allocation.

Just-in-Time vs Demand-Driven Manufacturing Infographic

industrydif.com

industrydif.com